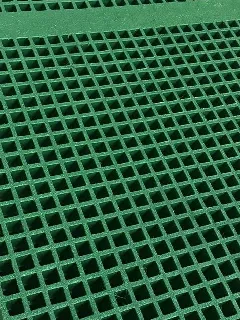

ZJ Composites frp filter tank

Links

-

-

a. Sealing Mechanisms:

-

- Mechanical Seals: Provide a tight seal and reduce leakage.

-

- Head: Calculate the total head required (static head plus friction losses).

-

Function: Seals prevent slurry from leaking out of the pump and protect the internal components.

-

-

-

Casting slurry pump parts are designed to withstand the rigors of handling abrasive materials, but they too require careful monitoring and timely replacement. The quality of the casting, the material used, and the operating conditions all influence the wear rate of these parts. By selecting high-quality casting slurry pump parts and implementing a regular inspection routine, you can better manage wear and optimize the replacement cycle. This approach ensures that your pump continues to operate efficiently, even in demanding environments, and helps to avoid costly breakdowns.

-

3. Consider Material and Design

-

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.

-

-

Wet parts in a pump, including the impeller, casing, and liners, are continuously exposed to the fluid being pumped, making them prone to wear. Monitoring the condition of these wet parts is crucial for maintaining pump performance. Regular checks and the use of wear indicators can help you determine when a pump wet end replacement is necessary. By establishing a monitoring routine and setting clear wear thresholds, you can replace these components before they fail, thus avoiding unscheduled downtime and extending the overall lifespan of the pump.