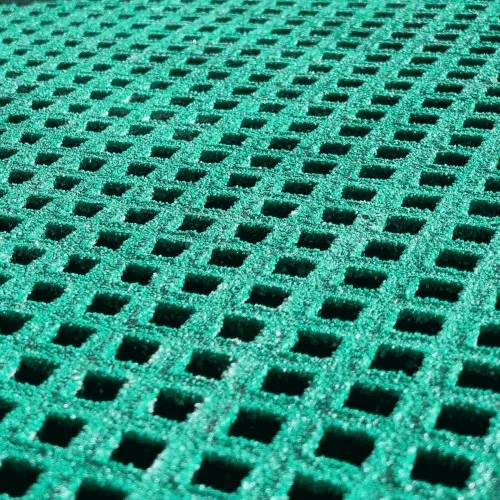

floor grating price

-

3. Customizable Fibre Reinforced Plastic can be molded into various shapes and sizes, making it easy to customize according to specific industry requirements. This flexibility allows manufacturers to produce tanks that fit perfectly within existing infrastructure, optimizing space and efficiency.

...

Links

-

4. Check Pump Performance Curves

-

-

-

The choice between a vertical inline pump and a centrifugal pump depends on various factors, including space constraints, pressure requirements, and maintenance considerations. By carefully evaluating your system's needs and the specific advantages of each pump type, you can select the right pump that meets your operational requirements and ensures long-term reliability.

-

Sand and Gravel Separation in Quarrying with Horizontal Slurry Pumps

-

The shaft transmits power from the motor to the impeller, while the bearing assembly supports the shaft and allows it to rotate smoothly. The durability of these components is essential, as they must endure continual mechanical stress and the harsh conditions present within the slurry.

-

-

By continuously increasing investment in new product research and development, as well as product upgrades , MineMaxx aim to further enhance the technical reserves of new ceramic desulfurization pumps and effectively extend their service life. In response to the current high wear and corrosion working environment in the desulfurization market, MineMaxx has completed the technical reserve work for more than 10 new ceramic desulfurization pumps, produced 2 complete machines, and fully provided customers with higher quality and more innovative products and services, saving user product spare parts procurement costs, improving user economic benefits, and providing strong support for subsequent market breakthroughs. Recently, the MM700D-A90 ceramic desulfurization pump has been successfully delivered to a user site in Inner Mongolia.

Selecting the right type of impeller is essential for the pump's performance. For instance, if a pump is expected to handle a high volume of sewage containing large solids, an open impeller would be more effective. Conversely, if the pump is mainly handling gray water with minimal solids, a semi-open or enclosed impeller would suffice.

Efficient pump operation is critical for many industrial processes, and the maintenance of pump wear parts plays a vital role in ensuring reliability and reducing downtime. Properly managing the replacement cycle of components is essential for maintaining optimal pump performance. This article explores how to determine the best replacement cycle for these critical components, focusing on wear assessment, runtime tracking, and performance monitoring.

Simplified Installation with Vertical Inline Centrifugal Pumps

Function: The expeller and expeller rings work together to reduce the pressure and minimize leakage from the pump.

One of the most significant advantages of vertical multistage centrifugal pumps is their compact footprint. In deep pit applications, space is often at a premium, and the vertical design allows for efficient use of limited space. These pumps are designed to handle high pressures while occupying minimal horizontal space, making them ideal for applications where surface area is restricted. The multistage configuration also enables these pumps to deliver high pressure over long distances, which is particularly useful in deep pit environments where the pump needs to lift slurry from significant depths. By optimizing the design of vertical multistage centrifugal pumps, engineers can ensure that these pumps provide reliable performance in even the most confined spaces.

In the world of fluid handling, the choice between a vertical inline pump and a centrifugal pump can significantly impact system efficiency, maintenance, and overall performance. Both types of pumps are widely used in various industries, but they have distinct characteristics that make them suitable for different applications.

- **Particle Size: Identify the maximum particle size in the slurry.

Expand product application areas and shorten the conversion cycle of new product contracts. With the successful development of the company's first 300FMM-B90 froth slurry pump, combined with the results of market research, so far, MineMaxx has again completed the technical reserve of three new products of froth slurry pump, and completed the design of 65MZJ froth slurry pump, realizing the full coverage of conventional pump types. Recently, MineMaxx signed a contract with a company in Hangzhou for two sets of 100FZJ-B50 froth slurry pumps. The products involved in the contract are the new products of the company's technical reserve project. After receiving the contract, the relevant departments of the company quickly carried out work, and completed the technical transformation of all new product contracts in only three days, providing strong technical support for the delivery of subsequent new product contracts.