Can Electrical Tape Catch Fire?

tape for marking floors. Unlike other methods of floor marking such as paint, tape can be quickly laid down without the need for drying time. This is especially beneficial for businesses that need to make temporary markings or frequently change their floor layout. Additionally, when it comes time to remove the tape, it can be peeled off easily without leaving behind any residue or damage to the floor surface.

Silicone tape can function effectively within a wide temperature range, from freezing cold to scorching heat. This adaptability makes it an excellent choice for various climates and applications.

In addition to its practical uses, insulating tape is also popular for creative projects and crafts. Its flexibility and adhesive properties make it a versatile material for various DIY projects. From decorating phone chargers to making colorful bookmarks, insulating tape can add a fun and unique touch to everyday items.

3. Durability and Longevity Fireproof gasket tape is engineered to stand the test of time. It is resistant to degradation caused by UV light, moisture, and extreme temperatures, ensuring a long-lasting seal that minimizes the need for frequent replacements. This durability is particularly beneficial in harsh industrial environments, where traditional tapes may fail prematurely.

In the realm of home repairs and DIY projects, having the right tools and materials at your disposal can make all the difference. One product that has gained significant popularity for its versatility and reliability is Flex Seal Flex Tape. Among its various sizes, the Flex Tape Black 4 x 5 version stands out for its utility in addressing a myriad of household needs.

Conclusion

As described in the article “How Polyimide Tapes are Made“, tapes are composed of two distinct layers, each of which is critical to the properties of the final product. The first layer is the backing material, and whether this is polyimide film (the generic verison of DuPont’s Kapton), polyvinyl chloride (PVC), Polyethylene terephthalate (PET), or some other plastic, cloth or paper material, this layer is selected to provide half of the tape’s final properties. The other half is determined by the adhesive layer applied to this backing layer.

Advantages of Polyethylene:

One of the most common uses of heat tape is in plumbing systems. During winter months, exposed pipes are at risk of freezing, which can lead to ruptures and significant water damage. By applying heat tape directly to the pipes, homeowners can ensure that the water remains at a safe temperature, protecting their property from costly repairs.

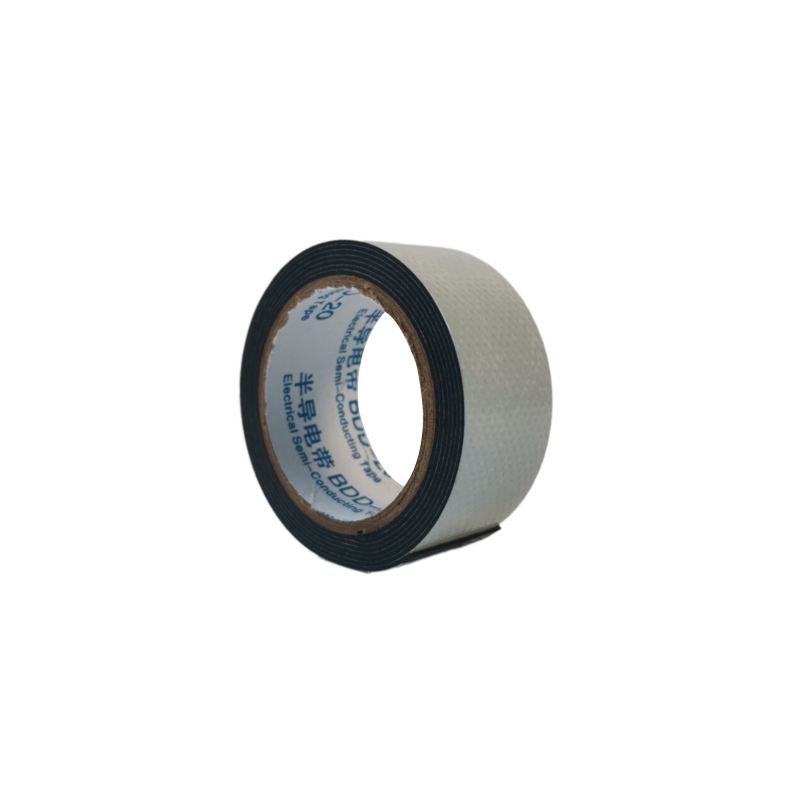

PVC Electrical Tape

Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings

Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings silicone insulation tape.

silicone insulation tape. Measure and Cut: Cut the desired length of silicone tape. Make sure it's slightly longer than the area you need to cover.

Features of self-amalgamating tape

Wire Sizing and Component Types

In plumbing repairs, amalgamating rubber tape is often used to fix leaks and reinforce pipe joints

. The tape can be applied to the damaged area and wrapped tightly to create a waterproof seal. Its flexibility and strength make it an ideal solution for emergency repairs or as a temporary fix until a permanent solution can be implemented.amalgamating rubber tape

Another important feature of Flex Tape 4 is its strength. The tape is rated to hold up to 50 pounds of weight per square inch, making it suitable for a wide range of applications. Whether you need to repair a leaky pipe, patch up a hole in your roof, or fix a broken garden hose, Flex Tape 4 is up to the task.

flex tape 4

The advantages of incorporating fire-resistant electrical tape in electrical work are manifold. First and foremost, it enhances safety. By using fire-resistant materials, the risk of electrical fires can be significantly reduced. This is particularly vital in environments with high heat sources or where electrical systems are overloaded.