4. Labor Labor costs can vary widely depending on the region and the complexity of the project. Skilled labor is essential for ensuring that the steel framework is erected safely and correctly, and the availability of skilled workers can affect the timeline and overall cost of construction.

steel warehouse building cost

In the context of sustainable farming, agricultural sheds can also play a role in the adoption of environmentally friendly practices. For instance, using materials like recycled metal or wood in construction can lessen the ecological footprint of the farming operation. Additionally, modern sheds can integrate renewable energy sources, such as solar panels, to reduce energy consumption.

With environmental sustainability becoming an integral part of the construction industry, metal buildings offer an eco-friendly alternative. Metal can be recycled, reducing the environmental impact associated with traditional materials. Moreover, by choosing energy-efficient insulation and solar panel options, homeowners can reduce energy costs and minimize their carbon footprint.

In recent years, metal garage kits have become increasingly popular among homeowners and businesses alike. The versatility and durability of these structures make them an excellent investment for anyone in need of additional storage or workspace. One of the most appealing aspects of metal garage kits is their affordability, with many options available at prices that reflect a 30% to 40% savings compared to traditional construction methods. This article will explore the various benefits of choosing a metal garage kit, focusing on their cost-effectiveness, durability, and ease of installation.

On average, prefab metal buildings can cost anywhere from $10 to $50 per square foot, depending on the factors mentioned above. For instance, a simple carport might cost between $2,000 to $5,000, while a larger commercial building could range from $20,000 to $100,000 or more. It’s essential for buyers to get quotes from multiple manufacturers and contractors to find the best deal.

Distribution centers function as vital hubs in the supply chain. They serve to consolidate and redistribute goods, acting as a bridge between manufacturers and retailers or consumers. Unlike warehouses, distribution centers focus on rapid processing and sorting of products for quick delivery. These buildings are often strategically located near major transportation routes or urban areas to enhance efficiency. Advanced logistics and technology, such as robotics and AI, are increasingly integrated into the design of distribution centers to streamline operations and reduce handling time.

industrial building types

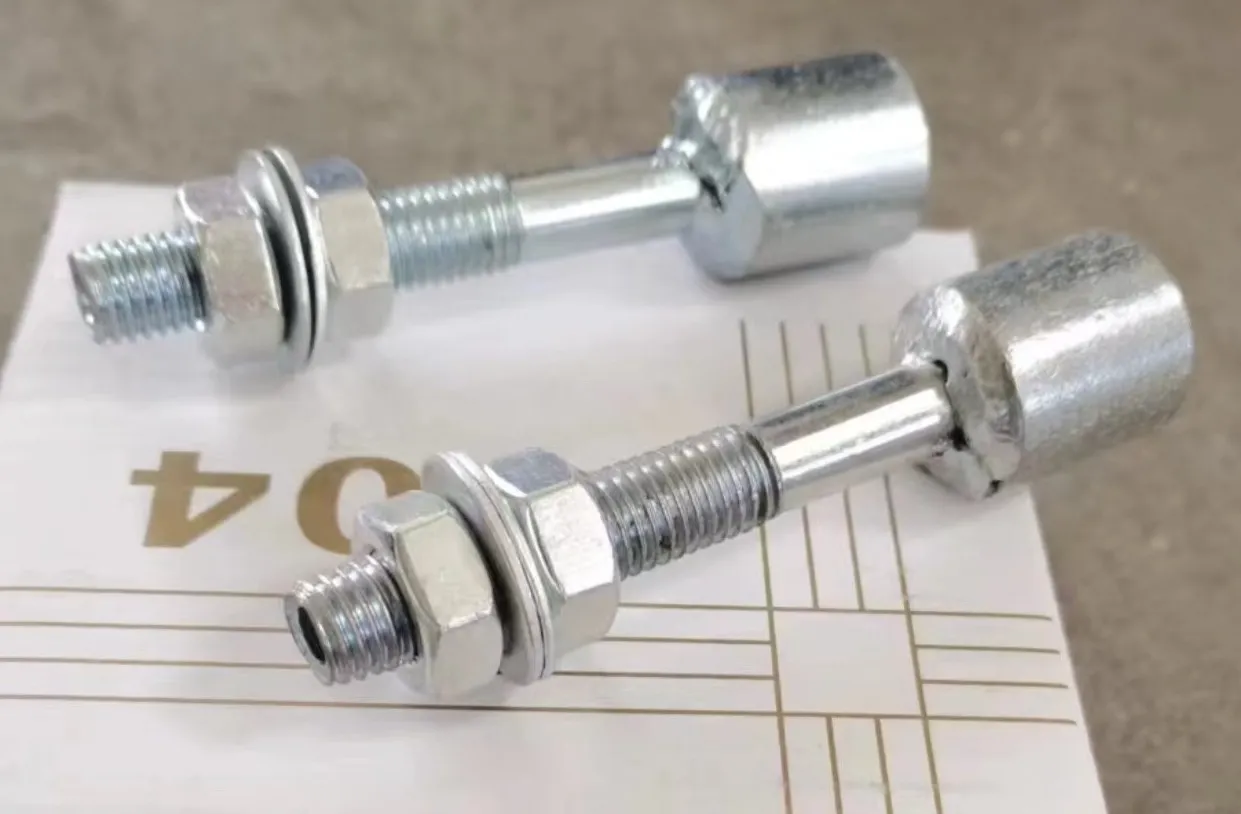

Industrial building suppliers are companies that provide materials, equipment, and services necessary for the construction of industrial facilities. Their offerings typically include structural components such as steel beams, concrete blocks, and prefabricated panels, along with essential tools and machinery. Additionally, these suppliers may also offer logistical support, project management services, and even consultation on design and compliance with industry standards.

- Ventilation When storing equipment or using the garage as a workshop, proper ventilation is essential to prevent heat buildup and moisture accumulation. Look for kits designed with ventilation features.

However, converting agricultural buildings is not without challenges. Local zoning laws and building codes may restrict how these structures can be repurposed. Furthermore, maintaining the integrity and character of the original building while upgrading it to meet modern standards can be complicated and costly. Owners must navigate the delicate balance between preserving historical aspects and incorporating contemporary functionality. Collaborating with architects and designers who understand both the historical significance and practical needs of these projects is crucial for success.