In conclusion, while steel is generally stronger than iron, both metals have their own unique advantages and disadvantages. Steel is preferred for its superior strength, durability, and resistance to corrosion, making it a versatile and widely used material in various industries. On the other hand, iron still has its place in certain applications where its unique properties, such as ductility and wear resistance, are more desirable.

Wrought iron: It is made from the raw element of iron. Professional workmanship with hammer marks and other signs of blacksmith techniques. Wrought iron will bend under extreme heat and does not dent, dimple, or collapse.

It is suitable for a wide range of door types and sizes, making it an ideal choice for both residential and commercial applications It is suitable for a wide range of door types and sizes, making it an ideal choice for both residential and commercial applications

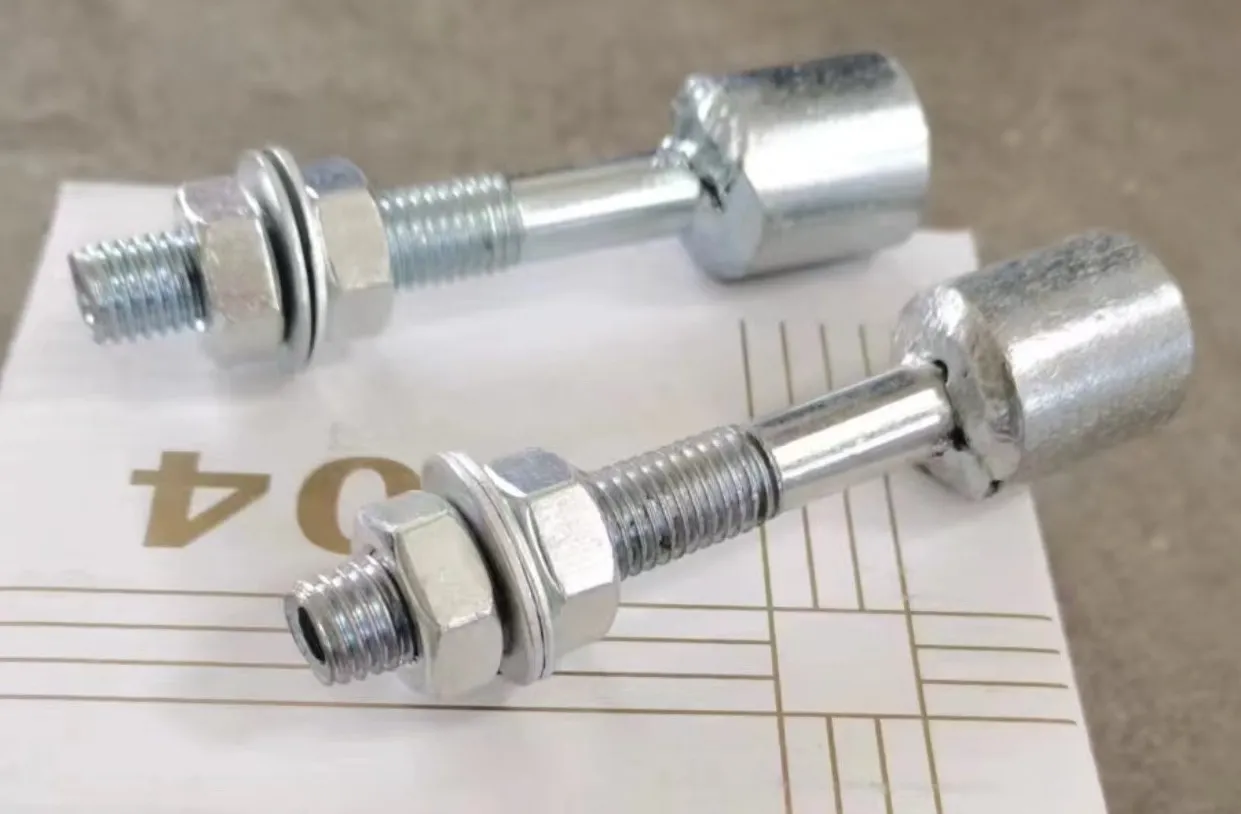

It is suitable for a wide range of door types and sizes, making it an ideal choice for both residential and commercial applications It is suitable for a wide range of door types and sizes, making it an ideal choice for both residential and commercial applications new rollers for sliding door. Whether you're updating your home or designing a new commercial space, this roller system offers a versatile solution that can be tailored to meet your specific needs.

new rollers for sliding door. Whether you're updating your home or designing a new commercial space, this roller system offers a versatile solution that can be tailored to meet your specific needs.  They provide a secure barrier while maintaining an open and airy feel, perfect for both residential and commercial properties They provide a secure barrier while maintaining an open and airy feel, perfect for both residential and commercial properties

They provide a secure barrier while maintaining an open and airy feel, perfect for both residential and commercial properties They provide a secure barrier while maintaining an open and airy feel, perfect for both residential and commercial properties ornamental iron post.

ornamental iron post. Hand-forged ornamental iron was the first type of steel fencing dating back to the early 1800’s. Individual parts were hand-forged in iron shops, where the steel was heated at high temperatures and formed into shape by a black smith. Forged metal is extremely durable but due to the process involved of forging each part takes a considerable amount of time to make which drives the cost up. Today, this type of fencing is extremely rare with very few craftsmen making this type of ornamental fencing.

Moreover, a secure fit also prevents any potential tampering, adding an extra line of defense against burglars Moreover, a secure fit also prevents any potential tampering, adding an extra line of defense against burglars

Moreover, a secure fit also prevents any potential tampering, adding an extra line of defense against burglars Moreover, a secure fit also prevents any potential tampering, adding an extra line of defense against burglars security screen door rollers.

security screen door rollers. Speaking from personal experience as a welder, steel is a lot easier to work with than iron. If someone manages to break a piece of steel (which isn’t easy), repairing it is a simple matter of properly positioning the pieces and welding them together. In contrast, repairing a cracked or damaged piece of iron means heating the whole piece back up to nearly molten temperatures, then carefully welding it in stages--with pauses to reheat the piece--while sometimes giving it a whack with a hammer and hoping you don’t hear the tell-tale ping of a crack forming somewhere else. Iron is a finicky material.

small metal box with latch. Its sturdy latch provides security, ensuring that its contents remain safe and protected. Perhaps you use it to store your most precious belongings, knowing that they are always close at hand and secure from prying eyes.