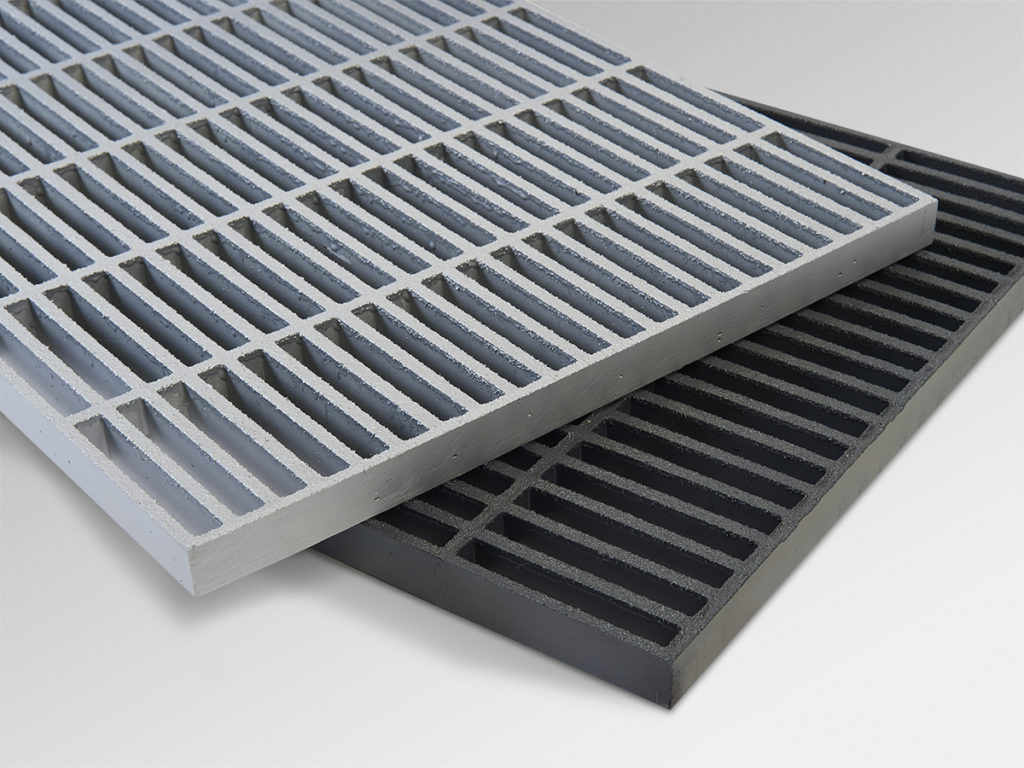

heavy duty fiberglass grating

Links

- At its core, a button bit represents the digital manifestation of a physical button press. It is a binary code, typically a sequence of zeros and ones, that instructs a device to perform a specific action when activated. This could be as simple as playing a video game or as complex as initiating a software program's operation. Despite its small size and simple concept, the button bit carries immense power, acting as the bridge between human intent and machine execution.

-

- Durability is another key advantage of fiberglass pipe insulation fittings. The material is resilient against corrosion, weathering, and mechanical stresses that often plague piping systems. This resilience translates into less frequent maintenance and longer service life for the insulation, offering cost savings over time. Furthermore, the non-combustible nature of fiberglass adds an extra layer of safety, making it suitable for applications where fire resistance is a priority.

- CPVC FRP Tanks Revolutionizing Storage Solutions

- In conclusion, cutting drill bits offer a convenient solution for those looking to streamline their drilling and cutting processes. By combining these two functions into one tool, they provide increased efficiency and versatility. Whether you're a professional contractor or a weekend hobbyist, investing in high-quality cutting drill bits can significantly improve your workflow and results.

Fiberglass Grating

It is also non-slip, making it safer for walking spaces. It is also non-magnetic and non-sparking, creating a safer environment.

This can help to simplify the application process and reduce the risk of over-application, which can have negative environmental impacts This can help to simplify the application process and reduce the risk of over-application, which can have negative environmental impacts

This can help to simplify the application process and reduce the risk of over-application, which can have negative environmental impacts This can help to simplify the application process and reduce the risk of over-application, which can have negative environmental impacts grp storage tank.

grp storage tank.  thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.

thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.

thread rod extension.

Construction Sites

MF Drill Rod Revolutionizing the Mining Industry The mining industry has undergone significant changes in recent years, with advanced technology playing a crucial role in enhancing efficiency and productivity. One such innovation is the MF drill rod, which has revolutionized the way drilling operations are conducted in mines around the world. MF drill rods are made from high-strength materials, such as alloy steel or titanium, which provide superior strength and durability compared to traditional steel drill rods. This makes them ideal for use in harsh mining environments, where conditions can be extreme and drilling requirements demanding. One of the key advantages of MF drill rods is their ability to reduce downtime and increase productivity. Traditional steel drill rods are prone to wear and tear, which can lead to frequent replacement and downtime. MF drill rods, on the other hand, have a longer lifespan and require less maintenance, resulting in significant cost savings for mine operators. Another significant advantage of MF drill rods is their ability to improve hole quality. The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality

The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality The superior strength and durability of these rods allow for higher drilling speeds and greater penetration depth, resulting in cleaner holes with better quality mf drill rod. This is particularly important in the mining industry, where accurate hole placement is critical for efficient ore extraction. In addition to their technical benefits, MF drill rods also offer environmental advantages. Traditional steel drill rods can generate significant amounts of scrap during the manufacturing process, which can have a negative impact on the environment. MF drill rods, on the other hand, are made from recycled materials and have a lower carbon footprint, making them an environmentally friendly alternative to traditional steel drill rods. Overall, the introduction of MF drill rods has had a profound impact on the mining industry, offering significant improvements in terms of efficiency, productivity, and environmental performance. As the demand for minerals continues to grow, it is likely that we will see further advancements in drill rod technology, leading to even more efficient and sustainable mining practices in the future.

mf drill rod. This is particularly important in the mining industry, where accurate hole placement is critical for efficient ore extraction. In addition to their technical benefits, MF drill rods also offer environmental advantages. Traditional steel drill rods can generate significant amounts of scrap during the manufacturing process, which can have a negative impact on the environment. MF drill rods, on the other hand, are made from recycled materials and have a lower carbon footprint, making them an environmentally friendly alternative to traditional steel drill rods. Overall, the introduction of MF drill rods has had a profound impact on the mining industry, offering significant improvements in terms of efficiency, productivity, and environmental performance. As the demand for minerals continues to grow, it is likely that we will see further advancements in drill rod technology, leading to even more efficient and sustainable mining practices in the future.

The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels

The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels 75mm drill bit.

75mm drill bit.

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure anchoring drilling rod and bits.

anchoring drilling rod and bits.