What Is the Purpose of Using FRP Manhole Covers?

Sustainability Considerations

After installation, it is vital to conduct a final inspection. Ensure that the cover opens and closes smoothly and that there are no misalignments. Regular maintenance checks should be scheduled to monitor the condition of the manhole cover and frame, particularly in high-traffic areas.

Types of Bathroom Grating

Gully drain covers are protective grates placed over drainage systems to allow water to enter while keeping debris, leaves, and larger objects from clogging the drains. They are typically situated in streets, parking lots, and other public areas where heavy rainfall can lead to water accumulation. The cover’s primary function is to facilitate proper drainage while ensuring pedestrian safety.

Scrap steel is melted in a crucible, induction, electric arc or reverberator furnace at 1500° C or 2700°F. The required alloys carbon and silicon, and flux to bind to impurities to create slag are added to the molten iron. The slag is lighter than iron and floats to the top from where it is removed. The molten iron is then poured into a metal ladle with a long handle which is then carried to the sand molds contained in the metal frames and poured through the riser. Green sand has a lower auto-ignition temperature than the temperature of the molten iron allowing the organic material present in the sand to use up all the oxygen present in the mold, preventing oxidation of the manhole cover. Trapped gasses can cause bubbles in the casting.

The durability aspect is crucial, as bollards are subject to constant impact and environmental challenges. With a protective sleeve, the lifespan of a bollard is significantly extended, which translates to lower long-term maintenance costs for municipalities. Easy to install and replace, these sleeves minimize the downtime of street features, ensuring that public spaces remain safe and functional.

Biking is not only a great form of exercise and transportation, but it is also an eco-friendly way to get around. As more and more people choose to bike instead of drive, the need for proper bicycle storage solutions has become increasingly important. One such solution that is gaining popularity is the wooden bicycle rack.

Conclusion

Space Efficiency

1. Smooth Edges The edges of the grate should be flush with the surrounding pavement to prevent tripping hazards. All transitions from the pavement to the grate should be seamless.

4. Versatility Cast iron gully grids can be customized to fit various applications, including residential, commercial, and industrial environments.

Challenges and Solutions

Gate valves are fundamental components in various industrial processes, known for their ability to provide a reliable seal and efficient flow control. Among the different materials used in their construction, SS316 (Stainless Steel 316) has gained prominence due to its outstanding properties and versatility. This article delves into the significance of SS316 gate valves, exploring their advantages, applications, and reasons for preference in various industries.

Conclusion

Furthermore, by ensuring the efficient operation of underground utilities, cities can promote a healthier environment. For example, regular maintenance of sewage systems helps prevent overflow and contamination, contributing to public health and environmental conservation.

Understanding Gate Valves with Handwheels Essential Components in Fluid Control

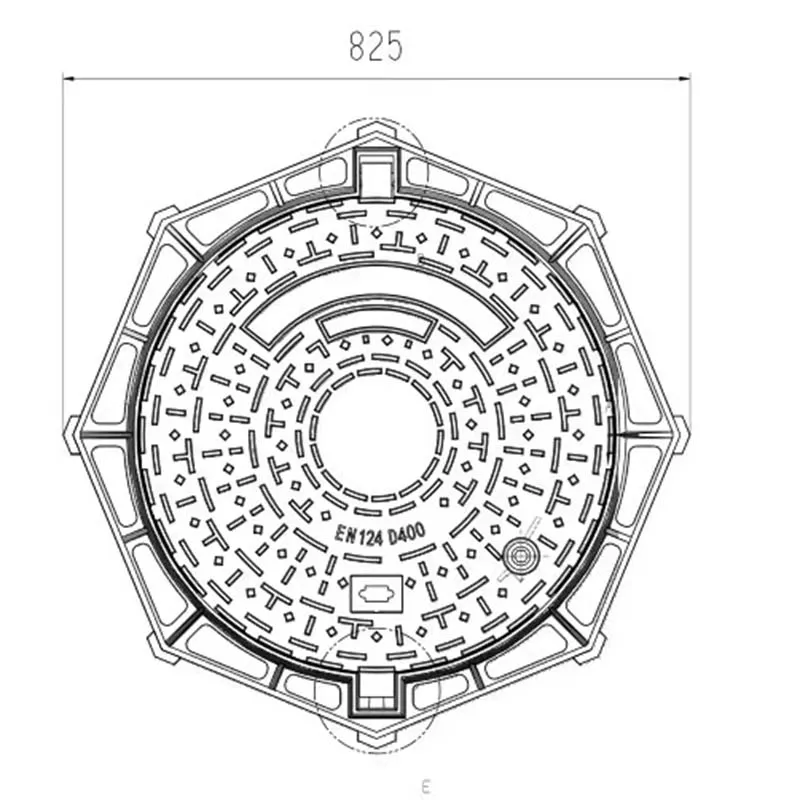

Cast Iron Manhole Cover is cast out of gray cast iron. As ductile cast iron is higher in strength, it is used for manholes that are supposed to take heavy loads ( Airport areas). The gray cast iron used for manhole cover manufacture is a combination of carbon and silicon. The carbon gives strength and durability to the element. The addition of manganese to the molten iron gives ductile cast iron.

Conclusion

A pipe dismantling joint is a unique type of pipe fitting designed to facilitate the removal and replacement of pipes without the need for extensive disruption to the surrounding infrastructure. It acts as a connection point between two sections of a pipeline while incorporating features that allow for quick disassembly. Typically, these joints allow for axial movement, enabling technicians to withdraw one pipe section from another safely and efficiently.