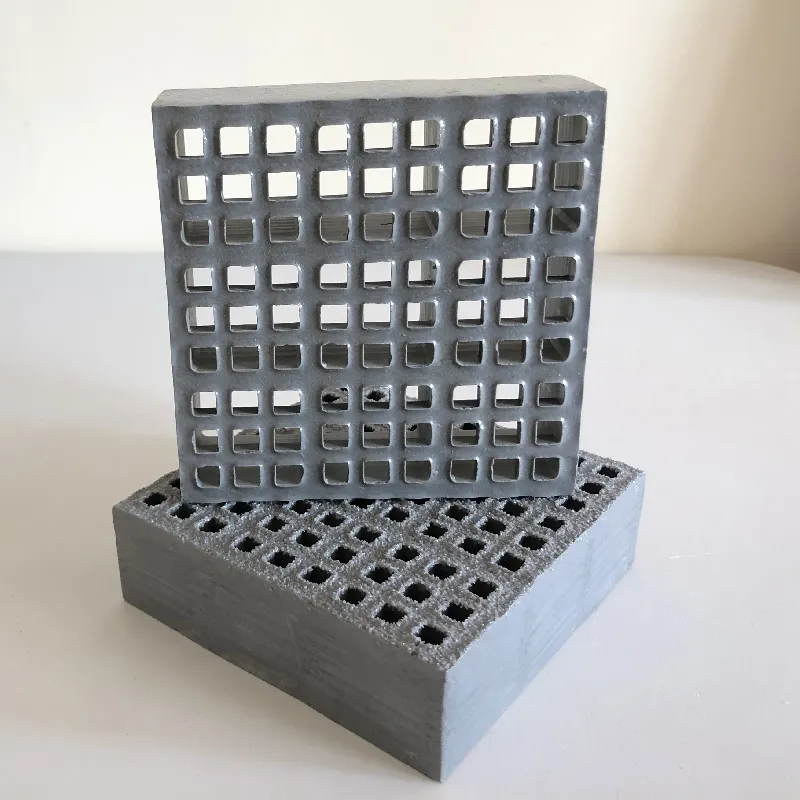

galvanised floor grating

Links

- Durable Rubber Flooring Solutions for Your Weight Room and Fitness Area

- 10 x 10 outdoor grass carpet

- Choosing the Best Flooring for Your Weight Lifting Area at Home

- Cost Analysis of Materials for Running Track Construction and Maintenance

- Choosing Acrylic Flooring Options for Your Basketball Court Setup and Performance

- epdm granules manufacturer

- Enhance Your Backyard with Premium Soccer Turf for Ultimate Play Experience

- Creative Ideas for Soft Play Playground Flooring Solutions

- cheap rubber mats for playground

- Different Varieties of Artificial Turf and Their Applications

- Dark Green Synthetic Turf for Eco-Friendly Landscapes and Sports Applications

- different types of fake grass

- artificial grass cost per sq ft

- cheap gym mat flooring

- epdm granules suppliers

- Durable Rubber Mats Designed for Safe and Efficient Lifting Operations

- 5% Wide Artificial Grass for Enhanced Outdoor Spaces and Aesthetic Appeal

- Durable and Comfortable Soft Gym Flooring for Ultimate Workout Experience

- Benefits of Installing Artificial Grass Around Your Pool Area for Safety and Aesthetics

- Durable Artificial Turf Rugs Perfect for Camping and Outdoor Activities

- Affordable Synthetic Grass Rolls for Budget-Friendly Landscaping Solutions

- Durable and Reliable Heavy-Duty Gym Mats for Maximum Workout Comfort and Support

- Cost Analysis of Football Turf Installation and Maintenance

- commercial playground swing mats

- Cost Analysis of Artificial Grass per Square Meter for Various Applications

- Essential Supplies Required for Installing Artificial Turf in Your Outdoor Spaces

- Affordable Options for Synthetic Grass Mats and Their Pricing Guide

- Durable Non-Slip Gym Mats for Effective Workout Sessions and Enhanced Safety

- Affordable Artificial Grass Options for Your Lawn and Landscape Needs

- Affordable Flooring Options for Your Home Gym Setup and Comfort

- 20mm artificial grass

- Choosing the Best Flooring Material for Running Tracks

- 1m x 1m gym flooring

- Benefits of Using Artificial Grass Rolls for Your Outdoor Spaces

- Durable Waterproof Flooring Solutions for Your Home Gym Essentials

- Durable Playground Rubber Grass Mats for Safe Outdoor Play Areas

- Costs Associated with Artificial Turf per Square Meter for Various Applications

- Benefits of Artificial Grass for Eco-Friendly Landscaping Solutions

- Durable Rubber Flooring Solutions for Gyms and Fitness Centers

- Durable Rubber Mats for Enhanced Lifting Performance and Safety in Workspaces

- black rubber workout mats

- Durable and Safe Outdoor Playground Mats for Kids' Active Play Adventures

- artificial grass per square meter

- Choosing the Best Protective Mats for Your Gym Flooring Needs

- Choosing the Best Flooring for Indoor Play Areas and Recreation Spaces

- aziende produttrici di erba erbosa

- Durable and Comfortable Flooring Solutions for Your Gym and Fitness Space

- Durable Rubber Mats for Protecting Exercise Equipment and Flooring During Workouts

- artificial lawn grass carpet

- Benefits of Installing Synthetic Grass in Your Outdoor Space

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire