grp grating manufacturer

Links

- In conclusion, aluminum window extrusion profiles represent a significant advancement in modern architecture. With their exceptional strength, durability, customizability, and thermal performance, these profiles offer numerous benefits over traditional materials. While they may come with a higher price tag, the long-term benefits they provide make them a worthwhile investment for any project seeking to maximize functionality, efficiency, and aesthetic appeal.

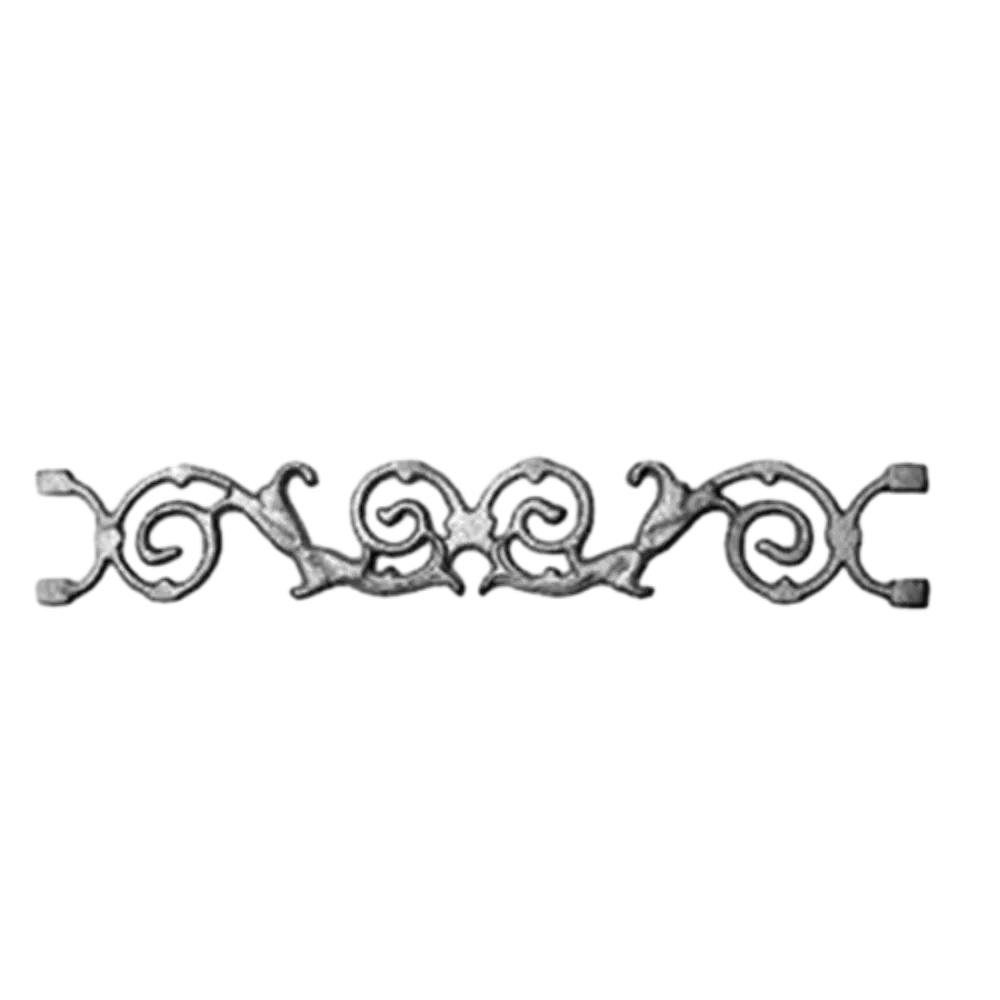

cast iron square collar. Its timeless design makes it easy to incorporate into any design scheme, and it can be paired with other decorative elements to create a cohesive and visually appealing space.

For instance, a fence adorned with ornate, curvaceous scrolls might enhance the charm of a historic building, while clean lines and minimalist designs could perfectly accentuate a contemporary structure For instance, a fence adorned with ornate, curvaceous scrolls might enhance the charm of a historic building, while clean lines and minimalist designs could perfectly accentuate a contemporary structure

For instance, a fence adorned with ornate, curvaceous scrolls might enhance the charm of a historic building, while clean lines and minimalist designs could perfectly accentuate a contemporary structure For instance, a fence adorned with ornate, curvaceous scrolls might enhance the charm of a historic building, while clean lines and minimalist designs could perfectly accentuate a contemporary structure wrought iron fence ornaments.

wrought iron fence ornaments. Various manufacturers price their specific aluminum profiles for windows and doors differently.

Thermal insulation aluminum extruded profiles for window frames

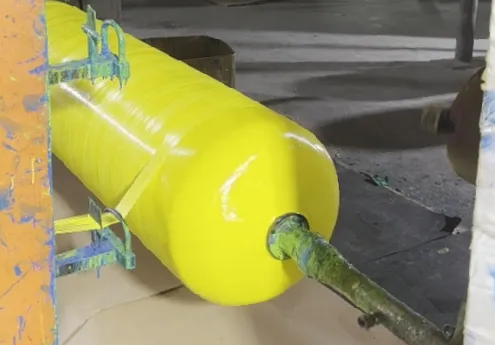

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility. Some steel and iron fence manufacturers will cut corners here. Especially in the rail-to-picket connection (the rail is the horizontal piece and the picket is the upright one). The worst ones we’ve seen is companies using rivets or screws to connect the pickets to the rails. While this works fine on a lighter aluminum fence, it does not work as well on an iron or steel fence. Not only does a weaker connection result in a ‘loose’ feeling panel, but the rivets can allow movement which can scratch down to bare metal and create rust spots.

Aluminum vs Wrought Iron Fence: What are the Differences and Which is Better?

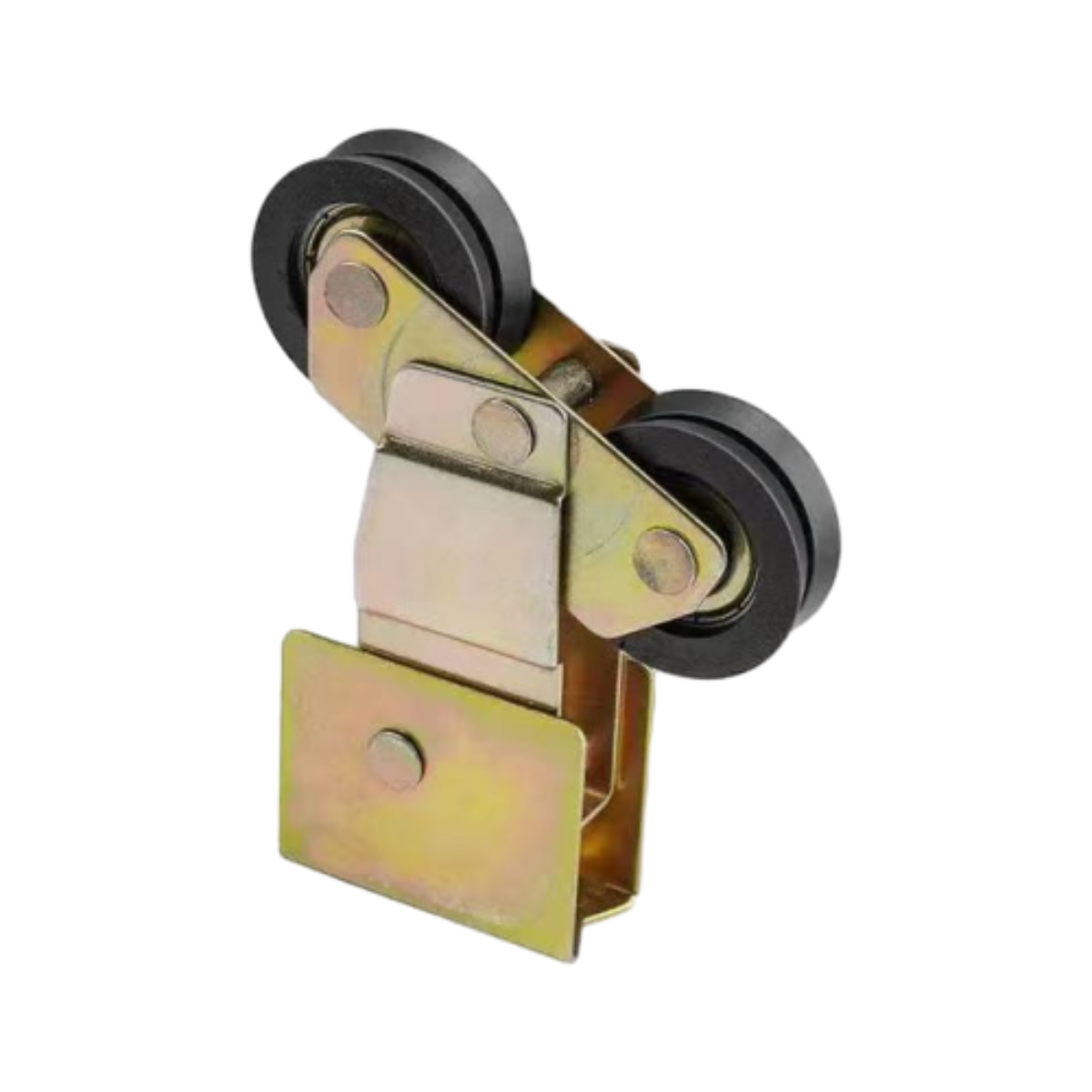

Type III Hard Anodize

In conclusion, choosing the right wheels for your sliding door track is crucial for ensuring smooth operation and a long lifespan for your door. By considering the materials, weight, environmental factors, and maintenance practices, you can keep your sliding doors in top condition, providing both functionality and aesthetics to your space.

Custom manufacturing

Check the available prices for these panels. Galvanized and powder coated. Fully Welded.

The most common component of contemporary wrought iron fences is the tubing made of iron or steel. The tubes are worked into forms by machines, and the manufacturers also utilize devices to produce the decoration traditionally used with a wrought iron fence. The lines are welded together to form wall panels, resulting in a robust iron fence.