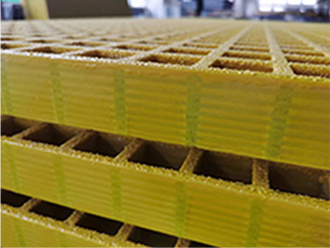

heavy duty bar grating

-

One of the most compelling advantages of prefabricated handrails is their cost-effectiveness. Traditional handrail systems often require extensive onsite labor, resulting in higher labor costs and potential delays. In contrast, prefabricated handrails are manufactured offsite and delivered ready to install. This significantly reduces the time and labor required at the construction site, which translates to lower overall project costs. Moreover, the prefabrication process allows for bulk production, which can also lead to amenable pricing, making these systems an attractive option for budget-conscious projects.

...

Links

-

The main factors causing metal rust: relative humidity of the atmosphere at the same temperature, the percentage of water vapor content and water vapor saturation content in the atmosphere, known as relative humidity. Under certain relative humidity, the corrosion rate of metal antirust oil is very small, but higher than the relative humidity, the corrosion rate increases suddenly. This relative humidity is called the critical humidity. When the humidity in the atmosphere is higher than the critical humidity, the metal surface will appear water film or water droplets, if the atmosphere contains harmful impurities, dissolved in the water film, water droplets, electrolytes and aggravate corrosion.

-

Hot dip galvanized wire is used in carbon structural steel, which is processed by drawing and hot dip galvanized. It is widely used in the manufacture of wire mesh, highway guardrail and construction projects. Electro galvanized wire is a kind of metal conforming material made of low carbon steel as core wire by wire drawing and electro galvanized process. Mainly used in wire mesh, highway guardrail and construction projects.

- Powder coating color is divided into: blade thorn rope blue, grass green, dark green, yellow. Spray blade gill net is made of hot-dip galvanized steel plate or stainless steel sheet stamped out of sharp knife sheet, high tension galvanized steel wire or stainless steel wire as core wire combination of blocking devices. Because the shape of the thorn rope is not easy to contact, so it can reach excellent protective barrier effect. The primary raw materials of products are galvanized sheet, stainless steel plate, high quality low carbon steel wire (electric galvanized, hot galvanized, coated plastic, plastic spray) wire, blue, green, yellow and other colors.

- The wire mesh is finished by fine welding of active welding equipment. The material can be divided into cold drawing wire, hot dip galvanized, cold galvanized, dip plastic and so on. To be used for bridge reinforcement, deck paving, building reinforcement, etc.

-

Now the production of stainless steel blade barbed rope unless it is a specially customized model, under normal circumstances are the use of a knife length of 22mm mold production, that is, we usually say bto-22 type. It’s not necessarily the case that there are specifications from 11mm to 65mm. Unless the customer insists on customizing the required length, the barbed rope manufacturer produces bto-22 stainless steel blade barbed rope.

-

Galvanized electric welding mesh refers to the mesh made of zinc alloy material, because of its high strength, high hardness, beautiful appearance, bright color and other advantages, become used in residential communities. Traditional electric welding mesh using iron bars, aluminum alloy materials, need to use welding and other technology, and the texture is soft, easy to rust, single color.

-

The wire used for wire mesh is made of low carbon steel wire, medium carbon steel wire, high carbon steel wire, stainless steel wire and other materials woven or welded. Production technology: general braid, embossed braid and spot welding type. If the steel wire as the material, after the equipment processing into a network, so called wire mesh.

- Determine the size of the crate based on the actual size of the dog as an adult. In general, the cage should be three times the size of the dog’s body, so that the dog has enough room to turn around and so on.

- 6, passivation to remove hydrogen parts should be passivation after the removal of hydrogen, passivation before the application of 1%H2SO4 or 1% hydrochloric acid activation 5~15s. Passivation shall be treated with colored chromate unless otherwise specified in the design drawings.

-

Nestor rolling cage, high-speed railway Nestor rolling cage and railway Nestor rolling cage are all produced, sold and installed in accordance with the technical requirements of the reference drawing of railway line 2012-8001. Nestor rolling cage is a kind of protective equipment emerging in railway in recent years. Nestor rolling cage is connected by Nestor connecting clip on the longitudinal tensile rib fixed on the bracket. The longitudinal tension and the support are connected with the Φ2.5mm cold-drawn galvanized steel wire around 2 laps and then tightened. The support is set in the column and the middle of the span of the protective fence of 3m. The other spans are only set with the upper column, and the support and the protective fence are connected with the bracket hoop. For the protective fence that has been installed with metal mesh, the Nestor roller cage is directly fixed on the transverse sheet and wire of the metal mesh with the cold-drawn galvanized steel wire of 2.5mm or the Nestor connection fastener.

-

Defects such as surface film and surface inclusions can be found and treated by conventional techniques in order to remove them locally from the surface of the deposition layer. Excess foam is formed when soap and surfactants such as saponified fats are brought into the tank.

- Plastic coated electric welding net: PVC plastic coated electric welding net is a kind of tall welding net, plastic coated electric welding net picture on the upper part of the protective barbed net, network cable is galvanized steel wire, plus PVC plastic treatment, in the protection of beautiful at the same time, ensure the firm and durable. Material: low carbon steel wire, PVC plastic coating manufacturing process: steel wire after welding plastic coating, can also be separate electroplating, hot plating and plastic coating. PVC plastic coated electric welding net use: industrial, agricultural, municipal, transportation and other industries of fence, decoration, protection and other facilities. PVC plastic coated electric welding mesh features: good corrosion resistance, strong weather resistance, anti-aging, beautiful and generous. Installation is simple and quick.

-

Heavy duty hexagonal mesh made of steel wire by special machinery woven into a hexagonal mesh net. This kind of mesh can be cut and assembled into fence mesh, mountain hanging mesh, vegetation three-dimensional mesh, composite, etc. Aliases: Gabion mesh, heavy hexagonal mesh, ecological mesh, wire mesh, etc.

-

Post time: 28-09-22 - Suitable for general engineering building wall, pouring concrete, multi-storey building, etc., in the structure of heat preservation and heat insulation system plays an important role, when the construction will be hot dip galvanized welded wire rack together wall of heat preservation and heat insulation board placement will be concrete pouring mold inside, outside the wall heat preservation and heat insulation board and one kind of live, after ripping into heat preservation and heat insulation board and wall body. The coating on the surface of the welding core is called the coating.

- The cage should be strong so that the bars cannot be bent or damaged by the parrot, and weak bars can be bent or damaged by the parrot and injure the parrot. Cages made of plastic coated railings can cause parrots to eat the coating and are not suitable. Quality cages are made of stainless steel, especially those made of colorful mild steel railings. Railing spacing is very important for the parrot’s safety, and the railing should always be small enough to prevent the parrot from poking its head out between the railing gaps. For small parrot species, column spacing of 1/2 inch (1.3 cm) is necessary. Medium parrot species such as grey parrots and Amazons require a 1 inch (2.5 cm) pitch, while great macaws can reach a pitch of more than 1 by inch (3.8 cm).

-

If the coating roughness is not caused by the above reasons, it may be caused by impurities in the plating solution. Can take a small amount of electroplating solution, after filtration test, then take a small amount of electroplating solution, after zinc powder treatment test, check the problem is caused by solid particles or copper, lead and other foreign metal impurities. Test them one by one and it’s not hard to find the cause of the problem. Galvanized iron wire coating foaming, binding force is not good.

-

The quantity should be the same as the contract, cold drawing, carefully record the quantity of each specification and packing method. If there is a label, check whether the label is correct and take a photo to confirm. Each roll of iron wire is fastened with galvanized packing tape, and then tied with a very strong transparent plastic bag. The coated iron wire is wrapped with white braided cloth, and the galvanized iron wire is wrapped with green braided cloth, so as to ensure that the packaging will not be lax in the transportation process.

-

2. Check the stabbing rope of the blade on time

-

Post time: 21-07-22 - Galvanized iron wire is divided into hot galvanized wire and cold galvanized wire (electric galvanized wire) is made of low carbon steel, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. Galvanized iron wire has good toughness and elasticity, zinc content can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. The products are widely used in construction, handicrafts, wire mesh, galvanized hook mesh, spackle mesh, highway fence, product packaging and daily civilian and other fields.

- The wide application of galvanized wire has brought great convenience to people’s production and life, but the production process of iron wire is also not to be underestimated. In industrial production, the production process of galvanized wire should be strictly controlled to ensure the quality of galvanized wire.

- Two, cold galvanized wire production process of galvanized. Galvanizing is the core process in the production of cold galvanized wire, mainly by soaking the steel wire in a molten zinc solution to form a zinc layer on its surface.

-

Post time: 24-03-23 -

Post time: 22-07-22 - 3, the external environment, the climate is dry and ventilated environment is not easy to rust.

- 2.25*2.25mm 10 meters per kilogram

- Cages are more often used to contain large dogs, which have a lot of strength. So the choice of dog cage must be strong, otherwise the dog is easy to break out of the dog cage.

-

For the specification of galvanized wire, the galvanized wire produced by our factory can range from No.8 to No.22, which refers to the BWG standard, that is, from about 4mm to 0.7mm, which can basically cover the type required by the customer. As for the raw material of galvanized wire, normally, we use Q195 mild steel, and some factories will also use SAE1006 or SAE1008. The following is the zinc coating, for galvanized wire, this is very important, the general zinc coating is about 50g/m2 to 80g/m2, some customers need high zinc galvanized wire, zinc coating can reach 200g/m2 to 360g/m2. The tensile strength of galvanized wire is usually 350n/m2 to 800n/m2. Then there is the packaging specification of galvanized wire. The specifications of small rolls of galvanized wire are 50kg/ roll, 100kg/ roll and 200kg/ roll. Of course, there are large rolls of galvanized wire, the weight can reach 300kg/ roll or 800kg/ roll.

- The policy of wire mesh mesh size, wire, square meter steel content, galvanized amount, etc., to consider the corrosion resistance of wire mesh ability and system safety! Wire mesh galvanized is more fierce than wire diameter, galvanized amount is very important, must be hot plating, welding after plating is better than the first plating after welding, as for wire diameter, summed up to consider the site construction and meet the needs of safety.

- In use, it can be well used in the annealing process to control its degree of hardness, mainly used in the construction industry for binding silk and tying. Its use is certainly not limited to arts and crafts. It is also widely used in the construction industry. Earlier woven lanterns were made of wire, and inside were placed suitable candles, which were hung in front of the door. It was very beautiful to go up at night.

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire