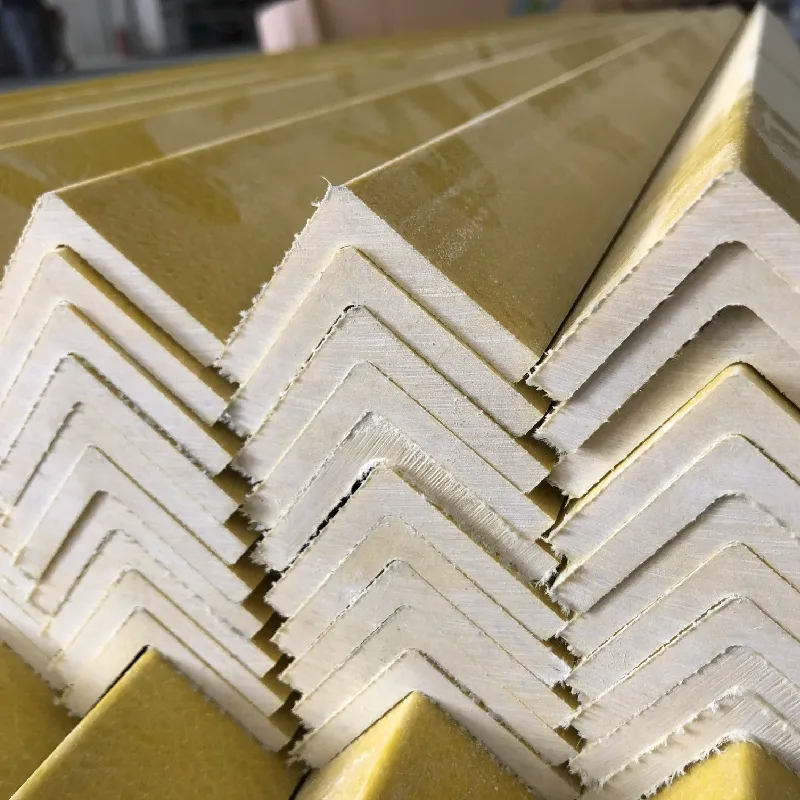

grp platform steps

Links

-

5. Global Reach The RDP market is global, and manufacturers often expand their operations to various regions. This not only helps them tap into new markets but also allows them to source raw materials more efficiently and respond to local industry demands. A global presence can enhance collaboration and knowledge transfer, benefiting clients worldwide.

-

The key to HPMC Company’s success is its unwavering focus on research and development. The company invests significantly in technological advancements and innovative processes to enhance product quality and performance. With a team of skilled scientists and industry experts, HPMC Company continuously explores new applications for HPMC, expanding its horizons and offering tailored solutions to its clients.

-

In conclusion, Hydroxypropyl Methylcellulose powder is an essential ingredient across various industries due to its outstanding properties and functionality. From construction to food, pharmaceuticals, and cosmetics, HPMC continues to prove its worth as a vital component that enhances product quality and performance. As industries evolve and sustainability becomes a priority, HPMC stands out as a natural choice for innovative formulations that meet both consumer and regulatory demands.

-

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether that plays a significant role in various industries, particularly in pharmaceuticals. With its unique properties and functionalities, HPMC is widely used as an excipient in drug formulations, making it an essential component in the modern pharmaceutical landscape.

-

30 -

- Tablet Coating HPMC serves as an excellent film-forming agent in tablet coatings, providing taste masking and protecting sensitive ingredients from environmental factors. This enhances the stability and appeal of the final product.

-

Moreover, HPMC has been instrumental in the construction industry. When added to cement-based products, it improves workability, water retention, and adhesion. These properties are vital for achieving stronger and more durable construction materials. HPMC-modified mortars and plasters have been associated with enhanced performance characteristics, making them preferable choices for modern construction applications.

-

1. Raw Material Selection

HPMC powder is also known for its thermoplastic behavior, which enables it to retain its properties under heat. This thermal stability makes HPMC an ideal component in formulations that require processing at elevated temperatures. Furthermore, HPMC is resistant to oil, grease, and many solvents, enhancing its utility in various environments.

-

Beyond construction material, redispersible polymer powders are widely used in the formulation of adhesives and sealants. The inclusion of RDP enhances the adhesion properties, allowing for stronger bonds to be formed on a variety of surfaces, including wood, metal, and plastics. This makes RDP particularly valuable in industries such as woodworking, furniture manufacturing, and automotive production.

-

What is Gelation Temperature?

-

Hydroxypropyl Methylcellulose (HPMC), a cellulose ether, has gained significant attention in various industries due to its unique properties and versatility. This polymer is derived from natural cellulose, which is modified to enhance its functional capabilities. One of the most appealing aspects of HPMC is its ability to form thick solutions and gels, making it an essential ingredient in pharmaceuticals, food products, construction materials, and personal care items. In this article, we will explore the characteristics, benefits, and applications of HPMC.

-

The Role of HPMC Importers

- Hydroxypropyl methylcellulose (HPMC) is a versatile additive that finds a wide range of applications in various industries. This compound, also known as hypromellose, is derived from cellulose and is used for its thickening, stabilizing, and emulsifying properties. Its chemical structure allows for a high level of control over viscosity, making it a valuable ingredient in many products. Let's explore some of the key uses of hydroxypropyl methylcellulose in different industries

- In the construction industry, HPMC is used as a thickener and water retention agent in cement-based mortars, plasters, and tile adhesives. It improves the workability of the mixture, allowing for easier application and better adhesion to surfaces. HPMC also acts as a dispersant, reducing the amount of water needed in the formulation, which in turn improves the strength and durability of the final product.

-

Conclusion

- HPMC manufacturers play a crucial role in supplying raw materials to a wide range of industries. In the construction industry, HPMC is commonly used as a thickener and water retention agent in cement-based products such as mortar, grouts, and tile adhesives. It improves the workability of these products and enhances their strength and durability.

-

Understanding HPMC Composition, Properties, and Applications

- In the food industry, HPMC viscosity grades are often used as thickeners, stabilizers, and emulsifiers in a wide range of products, including sauces, dressings, dairy alternatives, and gluten-free baked goods. The viscosity of HPMC can help improve the texture, mouthfeel, and shelf stability of food products, as well as enhance their appearance and flavor release. Higher viscosity grades of HPMC are typically used in products that require a thicker consistency or greater stability, whereas lower viscosity grades may be preferred for products that need to maintain a smooth and creamy texture.

2. Manufacturing Process The complexity and scale of the manufacturing process influence overall costs. Innovations in production technology that improve efficiency can lower prices, while outdated methods may increase production costs.

Applications of Dispersible Polymer Powder

While HPMC boasts numerous benefits, it's important to consider sustainability. Derived from renewable resources, such as wood pulp, HPMC production offers an environmentally friendly alternative to petroleum-based polymers. With increasing emphasis on sustainability in various sectors, the demand for natural derivatives like HPMC is expected to rise.

Quality control is paramount in the manufacturing of HEC since even minor deviations can significantly impact the properties of the final product. Manufacturers adhere to strict guidelines to ensure that HEC meets the necessary specifications required for its intended applications.

Hydroxypropyl Methylcellulose, commonly known as HPMC, is a versatile and essential additive used in the production of mortar. It plays a crucial role in improving the performance and workability of mortar, making it a popular choice among construction professionals.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose. It is widely used in various industries due to its unique properties, including its ability to form gels, its thickening capability, and its water-retention characteristics. Understanding the structure of hydroxyethyl cellulose is crucial for grasping how these properties come about and where they can be effectively applied.

1. Tile Adhesives In tile adhesives, RDPs improve the bond strength and shear resistance, allowing tiles to adhere more effectively to the underlying surface. This is crucial in ensuring that tiles remain firmly in place, particularly in areas exposed to moisture.

redispersible polymer powder wiki

The production of HPMC begins with the natural polymer cellulose, which is sourced from wood pulp or cotton. The cellulose is first treated with a series of chemical reactions involving methylation and hydroxypropylation. This process modifies the molecular structure of cellulose, enhancing its solubility in water and improving its functional properties.

Why Buy Hydroxyethyl Cellulose?

RDPs are also widely utilized in decorative plasters and texture coatings. They improve adhesion to various substrates, facilitate better workability, and contribute to water resistance. As a result, buildings can maintain their aesthetic appeal and structural integrity for longer periods, even in adverse environmental conditions.

The Uses of HPMC A Versatile Hydroxypropyl Methylcellulose

HPMC is also gaining traction in the construction industry, particularly as an additive in cement and plaster formulations. When added to mortars and tile adhesives, HPMC improves workability and provides better adhesion to surfaces. Its water retention properties help prevent the premature drying of cementitious mixtures, which can lead to cracking and reduced mechanical strength.

Quality control is paramount in the manufacturing of HEC since even minor deviations can significantly impact the properties of the final product. Manufacturers adhere to strict guidelines to ensure that HEC meets the necessary specifications required for its intended applications.

hydroxypropyl methyl cellulose manufacturer. HPMC is added to improve workability, water retention, and adhesion of these products. Our HPMC is designed to meet the specific requirements of construction materials, providing enhanced performance and durability.

Use of hypromellose in hydrophilic matrices has broad regulatory approval, is easy to use, has an excellent safety record, and has been extensively studied. This makes HPMC an excellent choice for pharmaceutical companies to develop and manufacture controlled release tablets.

Before modification can occur, the cellulose must be activated. This activation involves dissolving cellulose in a suitable solvent or suspending it in an alkaline solution. A common method is to mix cellulose with sodium hydroxide (NaOH), which swells the cellulose fibers and prepares them for chemical reaction. By increasing the surface area and accessibility of the cellulose, this pretreatment step is crucial to achieve effective substitution during the subsequent hydroxethylation process.

Cosmetic Uses

Environmental Aspect