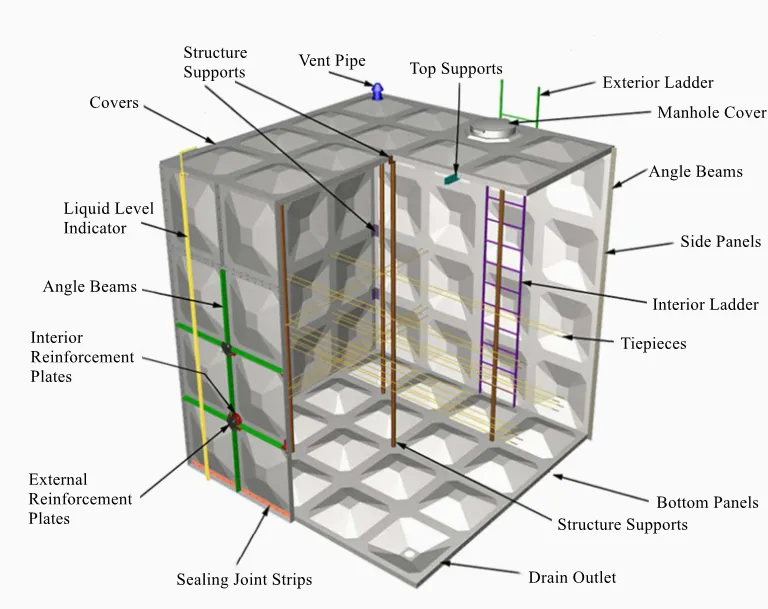

grp panel type water tank

Links

- Durable and Stylish Artificial Grass Edging Solutions for Your Outdoor Space

- athletic race track

- Choosing the Right Type of Sand for Your Artificial Grass Installation

- Benefits of Installing an Artificial Grass Sports Field for Athletes and Teams

- Durable EPDM Gym Flooring for Safe and Comfortable Workout Spaces

- erba falsa in vendita

- Cost Analysis of Synthetic Grass and Installation Expenses

- different types of artificial turf

- Eco-friendly Play Mats for Creative Outdoor Adventures and Safe Playtime Fun

- Cỏ nhân tạo ngoài trời

- Benefits of Installing Artificial Grass Around Your Pool Area for Safety and Aesthetics

- Benefits of Using Synthetic Grass for Landscape Design and Maintenance

- Choosing the Best Rubber Tiles for Safe Play Areas and Outdoor Recreation

- artificial turf high quality

- Durable Outdoor Rubber Mats for Safe and Fun Play Areas

- 20 Square Meters of Synthetic Turf for Lush Green Spaces and Easy Maintenance

- Choosing the Right Flooring Options for Your Workout Space

- Effective Solutions for Protecting Your Home Gym Flooring from Damage and Wear

- Choosing the Best Custom Weight Room Flooring for Your Gym Needs

- Affordable Gym Flooring Options for Budget-Friendly Fitness Spaces

- artificial lawn mat

- Benefits of Rubber Flooring for Weightlifting and Home Gyms

- Durable PVC Turf Mats for Sports and Outdoor Activities

- Choosing the Best Rubber Flooring Options for Playground Swing Sets and Safety

- 400 meter running track

- Durable and High-Performance Gym Flooring for Intense Workouts and Heavy Use

- Affordable Artificial Grass Carpet Options for Your Home and Outdoor Spaces

- cost to build artificial turf soccer field

- backyard turf football field

- 300 Meter Track Run Performance Analysis and Training Insights

- Choosing the Best Flooring for Professional Gym Environments and Performance Optimizations

- Designing and Maintaining an Outdoor Athletic Track for Optimal Performance and Safety

- Choosing the Best Outdoor Synthetic Grass for Your Space and Lifestyle

- 1 4 gym flooring

- artificial grass per square foot price

- Affordable Synthetic Turf Options Available for Your Landscaping Needs Today

- Choosing the Perfect Floor for Your Luxury Home Gym Experience

- artificial grass mat wholesale dealer

- EPDM Rubber Granules for Durable and Versatile Surfacing Solutions in Various Applications

- artificial grass front yard

- Best Options for Gym Flooring to Enhance Your Workout Space and Safety

- Affordable Turf Carpet Solutions for Outdoor and Indoor Spaces

- Designing the Perfect Outdoor Padel Court for Exciting Matches and Fun Gatherings

- eco friendly artificial grass

- average cost of artificial grass per square foot

- Choosing the Right Garden Matting for Swing Sets and Play Areas

- artificial lawn grass price

- Bulk Purchasing Options for Artificial Grass Solutions and Products

- Choosing the Right Mats for Olympic Weightlifting Training Sessions

- Design Ideas for Outdoor Garden Play Areas for Kids

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire