machine guarding systems

Links

- Reverse twisting of the barbed rope: first wrap the barbed wire around the main wire (that is, a single piece of iron wire) and then add an iron wire and twist together to form a double strand of barbed rope.

-

3, pay attention to the width of the cage seam

-

In general, the hardness of a metal is often considered to be the resistance of the material to plastic deformation, scratches, wear, or cutting. In the debugging of zinc wire dipping distance, keep the original speed unchanged, according to the time of dipping zinc, the diameter of steel wire, and then estimate the dipping distance. By adjusting the zinc immersion distance, the zinc immersion time of steel wire of various specifications is shortened by 5s on average compared with that before debugging, so that the zinc consumption per ton of steel wire is reduced from 61kg to 59.4kg.

-

Steel mesh galvanized: galvanized refers to the surface of metal, alloy or other materials coated with a layer of zinc to play a beautiful, rust prevention and other surface disposal technology. Now the first choice of method is hot dip galvanized, galvanized solution has cyanide bath and cyanide-free bath two categories. Cyanide bath bisects micro cyanide, low cyanide, medium cyanide, and high cyanide.

- Core diameter: according to customer requirements (mm)

- There are generally PVC plastic coating on the cattle net is in the original galvanized steel wire on the cover of a layer of dark green or gray plastic mold, to avoid the corrosion of wire diameter, is conducive to the progress of the anti-rust function of wire diameter. So the better the raw material, the higher the price. Zinc aluminum alloy cattle net is the best metal net on the market, the price is higher than hot dip galvanized raw materials. The service life is about 80-90 years, with excellent anti-corrosion function.

-

Post time: 24-03-23 -

Post time: 29-04-22 -

Post time: 31-10-22 - Hexagonal guardrail network custom structure is closely combined, the appearance is not concave and convex, with satisfactory corrosion resistance, oxygen resistance and other capabilities. Construction without a lot of manpower and material resources, can be operated on site.

- Galvanized iron wire is divided into hot galvanized wire and cold galvanized wire, using low carbon steel wire processing, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. It has good toughness and elasticity, and the amount of zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Galvanized iron wire can be cut off in the construction of the tie wire, the length of 20cm, 30cm and 40cm, can be cut off according to requirements.

-

It’s not clear why friends would want to use building nets for floor heating. What are its advantages in the floor heating project, the role of steel wire mesh is convenient for construction. Building mesh can better fix the pipe, conducive to the construction of the floor, improve efficiency. Anti crack function. The building network can improve the bearing capacity of the foundation of the thermal insulation board, the thicker the diameter of the steel wire of the building, the greater the bearing capacity, effectively prevent the appearance of cracks and cracks of steel wire mesh can improve the thermal shrinkage and contraction of cement, strengthen the tensile strength of cement, improve the quality of the heating project.

-

Galvanized wire coating is galvanized, aluminum plated, coated with nylon or plastic, etc. Zinc is divided into thin coating of steel wire after plating and thick coating of galvanized steel wire after drawing. The mechanical properties of thick coating are reduced compared with smooth steel wire rope, which should be used in severe corrosion environment. It is more resistant to corrosion, wear and heat than galvanized wire rope, using the first plating and then drawing method of production. Coated nylon or plastic wire rope is divided into two kinds of coated rope and coated stock after the rope.

- 3. When you travel with your dog, it will not cause anxiety to some friends because the dog is scattered in the car, or it will affect safe driving and bring risks.

-

Post time: 12-06-24 -

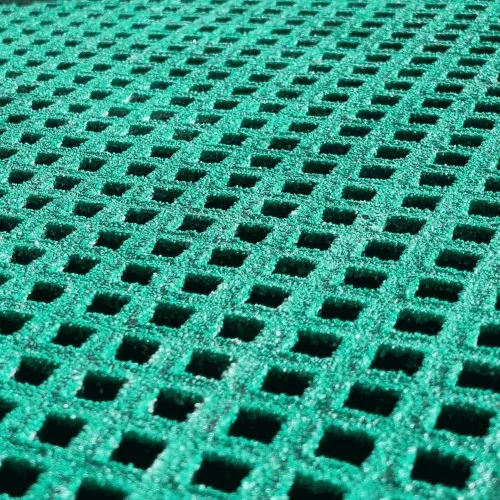

Fence use: generally used as a fence is a plastic-impregnated welded wire mesh with a height of 1.2 meters to 2 meters. Most of the mesh holes are 6cm, and the wire diameter varies from 2mm to 3mm.

-

The weight calculation method of hexagonal net is: the weight calculation method of hexagonal net: silk meridian.× silk meridian.× base x length x width ÷2=kg base: 1/2′=2.151′=1.273/4′=1.65/8′=1.875/4′=1.091′x1/2′ : 3′=0.4 silk warp. x silk warp. X 2x length x width ÷8×3=kg

- Hard black galvanized iron wire is made of low carbon steel wire by wire drawing machine. Hard black galvanized iron wire is the first feature of high hardness, bright appearance. It is mainly used for welding clothes hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawing. Soft black galvanized iron wire is the first feature of good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving technology, welding net, process products of welding.

- Steel mesh benefits: Compared with traditional handmade steel mesh, steel mesh has better elasticity and even spacing. When pouring concrete, the steel mesh is not easy to bend, and the thickness of concrete protective layer is easy to control and even. In bridge deck surfacing, measure the protective layer of steel mesh. The pass rate is 95 percent.

-

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

- After a long time of use, it will not rust like the corrosion layer on the surface of hot dip galvanized barbed rope, because the internal material of stainless steel barbed rope is the same as the material on the surface.

-

Post time: 20-06-22 - wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire