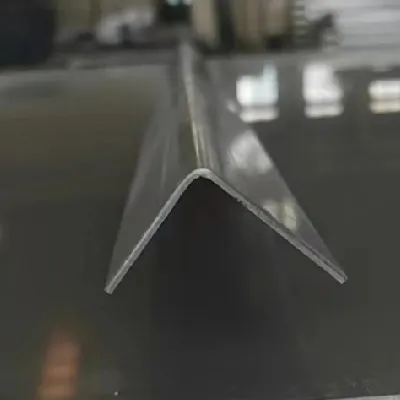

frp channel

Links

-

The impregnated hexagonal wire mesh will lose its original characteristics after corrosion, and will change in shape, color and mechanical properties, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment than dry environment easy corrosion, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated hexagonal wire mesh, prolong the service life of products.

-

According to the galvanized iron wire manufacturer, galvanized iron wire is the selection of excellent low carbon steel, through drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. The following points should be paid attention to in the use of galvanized iron wire:

-

Fence use: generally used as a fence is a plastic-impregnated welded wire mesh with a height of 1.2 meters to 2 meters. Most of the mesh holes are 6cm, and the wire diameter varies from 2mm to 3mm.

-

Therefore, when the zinc reaches saturation in the solid melt, the two elements of zinc and iron atoms are diffused with each other, and the zinc atoms diffused into (or infiltrated into) the iron matrix migrate in the lattice of the matrix and gradually form an alloy with the iron, while the iron diffused into the molten zinc liquid forms an intermetallic compound FeZn13 with the zinc and sinks into the bottom of the hot galvanized pot, that is, zinc slag. When the workpiece is removed from the zinc leaching solution, the surface of the pure zinc layer is formed, which is hexagonal crystal, and its iron content is not more than 0.003%.

-

Post time: 17-02-23 - (3) anti-freezing, residential protection, landscaping protection;

-

Post time: 18-07-22 - 3, whether positive and negative twist, whether bilateral silk is needed.

-

Now the production of stainless steel blade barbed rope unless it is a specially customized model, under normal circumstances are the use of a knife length of 22mm mold production, that is, we usually say bto-22 type. It’s not necessarily the case that there are specifications from 11mm to 65mm. Unless the customer insists on customizing the required length, the barbed rope manufacturer produces bto-22 stainless steel blade barbed rope.

- Bridge reinforcement reason is the bridge durability function is poor and aging, through the steel wire mesh reinforcement, can prolong the service life of the bridge, avoid the bridge cracks, collapse and other phenomena, steel wire mesh in bridge reinforcement anti-crack engineering can play an obvious effect, improve the construction speed of the project, enhance the concrete anti-crack function, induction of good economic benefits.

-

In general, the cost of hot dipping zinc is lower than that of other maintenance coatings. The reason is very simple. Other maintenance coatings, such as sand painting, are labor-intensive processes, whereas hot dipping zinc processes are highly mechanized and tightly controlled in-plant construction. Hot dip zinc coating can be visually and briefly tested for non-destructive coating thickness.

- The cage can be placed in a corner so that the bird can see what is going on around it and can retreat to the back of the cage without fear of being approached. The height of the cage from the ground is also important and is ideal slightly below eye level.

-

First, the tensile strength is durable

-

Post time: 24-02-23 -

Post time: 19-04-23 -

If the coating roughness is not caused by the above reasons, it may be caused by impurities in the plating solution. Can take a small amount of electroplating solution, filtration test, and then take a small amount of electroplating solution, with zinc powder treatment after the test, check the problem is solid particles or copper, lead and other foreign metal impurities caused by. One by one, it’s not hard to find the cause of the problem. Galvanized iron wire coating blister, poor adhesion.

- 2. When there are channels, ponds, lakes and other natural barriers on the side of the road, there is no need to worry about people and animals entering and illegally occupying the road land.

-

Post time: 06-04-23 - It is generally believed that the positive and negative twisting wire wire is not as durable as the thickness, common sense thinks so, but the positive and negative twisting wire wire is used in hot galvanized steel wire, which is more than 3 times the tensile strength of the iron wire, and the zinc amount is not lower than the hot plated wire

- Hook net use value is still very high, has a very good sex, and its manufacturing concise generous, beautiful, not in high temperature will fade, you can save a sum of maintenance costs, but also according to the different needs of the site to change the shape, to meet the needs of the site.

-

Post time: 14-03-23 -

The formation process of hot dip galvanized layer is between the iron matrix and the outside of the pure zinc layer, the formation of iron-zinc alloy process, the workpiece surface in hot dip plating when the formation of iron-zinc alloy layer, so that the iron and pure zinc layer is well combined. The process of large roll galvanized wire can be simply described as: when the iron workpiece is immersed in the molten zinc liquid, the first zinc and α-iron (body-centered) solid melt is formed on the interface. This is a crystal formed by the matrix metal iron dissolved with zinc atoms in the solid state. The two metal atoms are fused with each other, and the attraction between the atoms is relatively small.

-

Choose birds, raise birds before you need to choose the right birds, generally choose young birds, or minor birds, the requirements of health, strong activity, these birds are relatively easy to keep.

-

The application of electric welding net is more widely, at present it has replaced the use of other parts of the wire mesh, the cost of electric welding net is lower, the production speed is very fast, so it is very popular. Welding net galvanized before the need for processing is recrystallization annealing, because the welding net must maintain a no oxide and no other impurities of pure iron active surface, if you can not keep its surface clean will lead to a bad galvanizing effect, galvanized layer and iron material is not closely combined, so this step is necessary.

-

And high quality data and production cost and production conditions are bound, so some welding screen manufacturers did not meet the requirements of this aspect, natural in this case there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

- (5) Excellent process basis to ensure the uniformity of coating thickness, corrosion resistance is stronger;

- In addition, many luxury cat cage, dog cage, parrot cage, bird cage and flock bird cage, will use iron square tube. Luxury cage using iron square tube is generally as a cage body frame, and then on each side of the welded iron wire. Square tube cage is characterized by more beautiful shape design, cage body more solid, more surface treatment methods.

- 3, some stainless steel pet cage on the market does not use 304 or higher material, the so-called 202, 201 stainless steel is easy to rust, please users in the purchase of stainless steel pet cage as far as possible not to choose.

- Galvanized wire coating is galvanized, aluminum plated, coated with nylon or plastic, etc. Zinc is divided into thin coating of steel wire after plating and thick coating of galvanized steel wire after drawing. The mechanical properties of thick coating are reduced compared with smooth steel wire rope, which should be used in severe corrosion environment. It is more resistant to corrosion, wear and heat than galvanized wire rope, using the first plating and then drawing method of production. Coated nylon or plastic wire rope is divided into two kinds of coated rope and coated stock after the rope.

- 1. Pickling treatment: the steel wire is soaked in an acidic solution to remove the oil stains and oxidation layers on the surface to ensure the adhesion of the zinc layer.

-

Galvanized wire mesh is divided into hot dip galvanized wire mesh and cold galvanized wire mesh. Galvanized steel wire net selects the high quality low carbon steel wire, iron wire factory made by precision of automation machinery welding technology processing, smooth surface, firm structure, integrity is strong, even if the local cutting of galvanized steel wire net, or local also under pressure from loose phenomenon, after molding, wire mesh galvanized corrosion resistance good, has the advantage that the general steel mesh does not have.

-

Post time: 05-06-23 - Generally speaking, zinc is much more stable than iron, and will not rust in daily moisture or wet places. Z common galvanized iron wire equipment is usually we use the barbecue net, barbecue net generally requires to have a long service life, with galvanized iron wire equipment to wire on a layer of zinc, barbecue net is not easy to be corroded.

-

Are you familiar with galvanized wire mesh? Do you know what to pay attention to in the process of use?

-

Post time: 08-10-22 - The form of installation: in the top and the cage tied together at least should be like the stone cage net that is closely combined not easy to use bad. If the local dressing is suitable, the stability of the structure can be increased. There are a lot of mesh edge method, if the stone cage net only hook in the cage edge and not compiled in the cage edge, even in relaxation.

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire