When selecting the oil seal that is right for your machine, it is important that the oil seal be appropriate for the requirements of the usage environment and that it be easily acquired for replacement.

In this month's column, How to select the right oil seal, we conveyed the following points:

1) Oil seal shape and material should be selected based on the housing, substance to be sealed, pressure, rotational speed, total eccentricity, and air-side conditions.

2) Oil seals can show good sealing performance in combination with properly designed shafts and housings.

3) Oil seal performance is affected by not only the type and material of the selected oil seal, but also a variety of other factors, such as operating conditions, total eccentricity, rotational speed, the substance to be sealed, and lubrication conditions. For this reason, diligent care is required in oil seal selection.

Put the jack and wooden spacer under the sump and raise the engine just enough to free the supports.

Many seals come with a garter spring, found within the backside of the seal. It provides contracting pressure against the sealing surface. Making sure the spring seats correctly within the seal is an excellent first step.

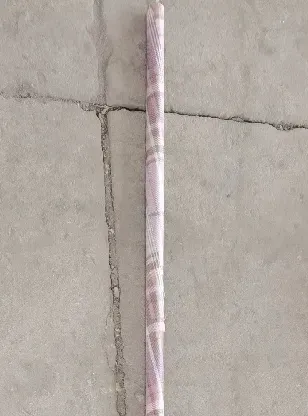

silicone rubber gasket. They can be easily deformed to fit various shapes and sizes of joints, making them suitable for use in a wide range of applications. This flexibility also allows them to compensate for minor misalignment or movement in joints, ensuring a tight seal.

silicone rubber gasket. They can be easily deformed to fit various shapes and sizes of joints, making them suitable for use in a wide range of applications. This flexibility also allows them to compensate for minor misalignment or movement in joints, ensuring a tight seal. Industrial Oil Seals: Applications and Importance

The oil seal gets its structural stability from an interior metal ring which serves as an inner skeleton. The outer skin is made of a more flexible material like nitrile rubber or other materials based on the physical environment of the seal. A spring on the lip of the seal supports the lip and keeps the lubricant from leaking. The lip construction is what blocks contaminants from outside.

How are they used?

Reconnect the battery . Start the engine and check carefully for oil or fuel leaks.

Figure 7: Recommended housing shoulder diameters

mm

sc oil seal. When lubricants are retained within the system, machines operate more efficiently, requiring less energy to perform at the same level. Over time, this reduction in energy consumption can lead to significant cost savings for businesses and reduced carbon footprints.

sc oil seal. When lubricants are retained within the system, machines operate more efficiently, requiring less energy to perform at the same level. Over time, this reduction in energy consumption can lead to significant cost savings for businesses and reduced carbon footprints.