frp grating walkway

-

Safety is another critical advantage of fiberglass stairs. Many fiberglass staircases are designed with non-slip surfaces, which significantly reduces the risk of falls, especially in wet or slippery conditions. This feature is particularly important in outdoor settings, such as pool areas or exterior entrances, where water accumulation can create hazardous situations.

...

Links

-

Multi needle quilting machines are inherently versatile, providing quilters with the ability to explore a wide array of designs and techniques. With multiple needle systems, quilters can easily switch between different thread colors and types within a single project. This allows for complex designs, intricate motifs, and personalized embellishments that would typically be challenging to achieve by hand. Additionally, many multi needle machines come with built-in design software that offers a library of patterns, enabling users to choose and customize designs at their fingertips.

-

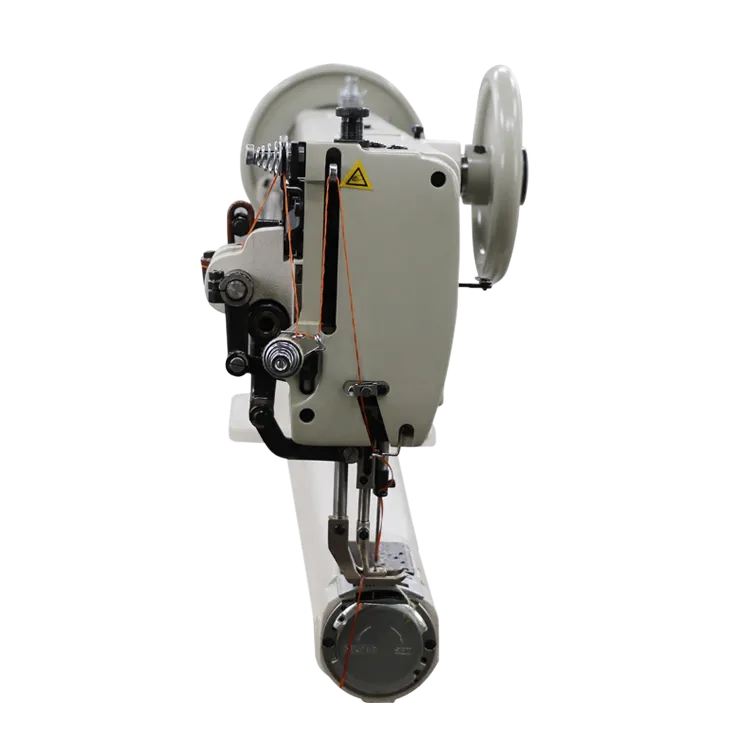

The Importance of Industrial Leather Sewing Machines

-

The Advancements and Applications of CNC Stitching Machines

Key Features to Look For

Understanding Auto Sewing Machines

3. Test Stitching Before starting the actual project, make a test run with scrap fabric to ensure you're comfortable with the sewing machine settings and stitch types.

These machines are equipped with multiple needles and thread options, enabling them to work with a variety of materials, from leather to synthetics. Some models even possess the capability to perform specialized stitching techniques that were traditionally challenging to execute, thereby expanding the possibilities for shoe design.

A heavy-duty post bed sewing machine is a powerful and versatile tool that is designed for use in industrial settings

. With its sturdy construction and high-performance capabilities, this type of sewing machine is perfect for tackling tough sewing projects and handling heavy fabrics with ease.The Walking Foot A Game Changer for Thick Fabrics

When it comes to sewing heavy materials like canvas, having the right equipment can make all the difference. Heavy-duty sewing machines are designed to handle the thickness and toughness of materials such as canvas, leather, and denim. These machines are not only built to withstand the rigorous demands of heavy fabrics but also provide the precision and efficiency needed for a variety of sewing projects.