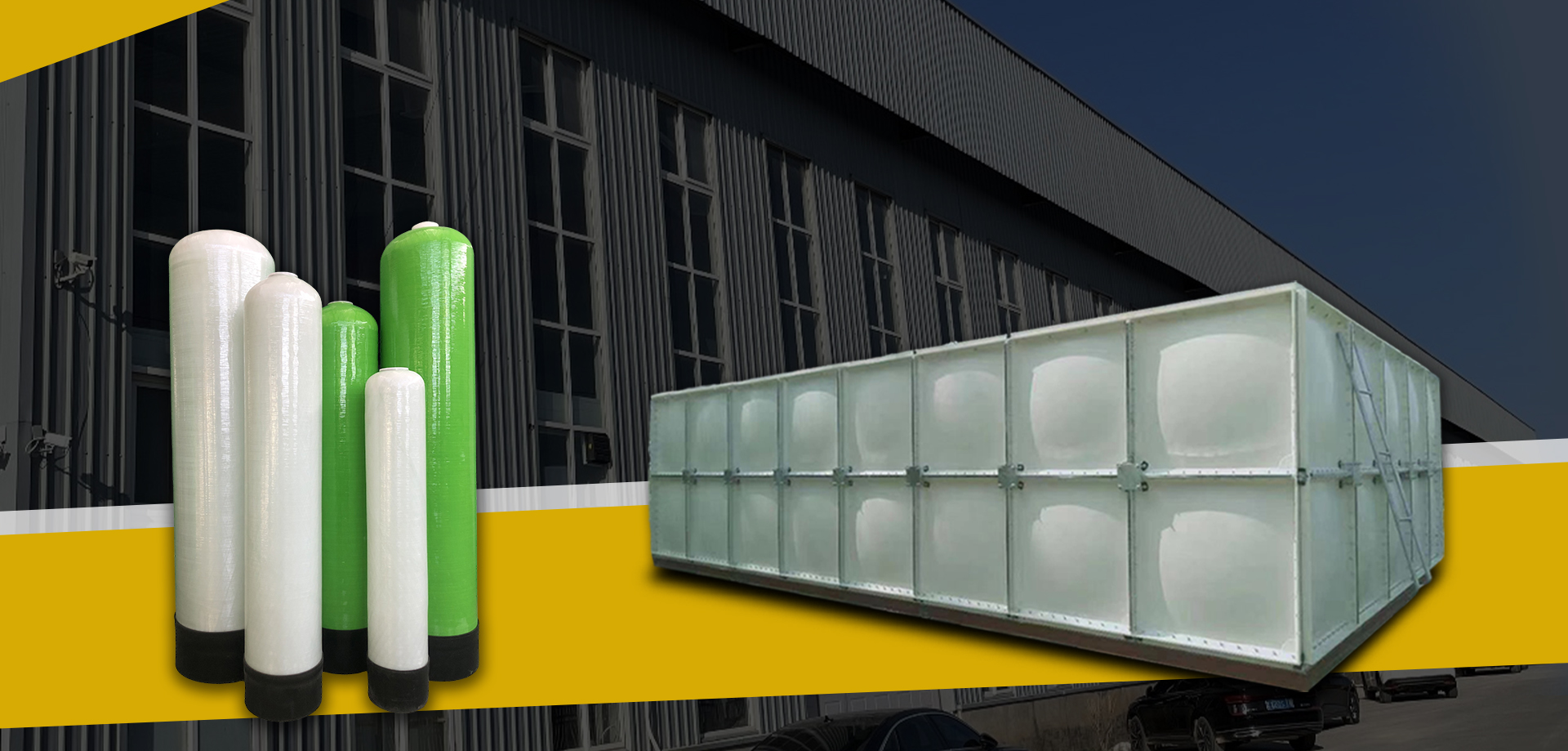

well water treatment systems

Links

For the housing stop installation technique, set the seal depth flush with the bore’s interior shoulder. This technique ensures that the seal is perfectly aligned with internal housing components. A depth gauge can be crucial here to confirm that the seal is positioned correctly.

power steering oil seal. The old seal is removed from the power steering pump, and a new seal is installed in its place. It is important to use a high-quality replacement seal to ensure that the power steering system functions properly and that leaks are prevented.

power steering oil seal. The old seal is removed from the power steering pump, and a new seal is installed in its place. It is important to use a high-quality replacement seal to ensure that the power steering system functions properly and that leaks are prevented. Oil Seals 101 – Part 1

Rotary Wheel Of Auto Parts

f7rtc spark plug. With proper maintenance and care, this spark plug will keep your engine running smoothly for years to come.

In conclusion, the 30-50-10 oil seal is a crucial component in ensuring the smooth and efficient operation of machinery and equipment. Its durability, efficiency, and ability to provide a tight seal make it an indispensable part of various applications. By investing in high-quality oil seals like the 30-50-10, businesses can minimize downtime, reduce maintenance costs, and improve overall productivity.

If the seal is being fitted to original equipment you may have some influence over the shaft and housing bore finish, but if you are replacing a worn seal you still need to take into account the condition of these 2 essential parts.

Ensure it perfectly fits the contours of the valve cover and the cylinder head Ensure it perfectly fits the contours of the valve cover and the cylinder head

Ensure it perfectly fits the contours of the valve cover and the cylinder head Ensure it perfectly fits the contours of the valve cover and the cylinder head changing a valve cover gasket. Some gaskets may require a sealer; follow the manufacturer's instructions for application. Carefully align the valve cover back onto the engine, lining up the bolt holes, and gently tighten the bolts in a crisscross pattern to prevent distortion.

changing a valve cover gasket. Some gaskets may require a sealer; follow the manufacturer's instructions for application. Carefully align the valve cover back onto the engine, lining up the bolt holes, and gently tighten the bolts in a crisscross pattern to prevent distortion. What are Oil Seals and how do they work?

Wipe the head and block absolutely clean with a cloth moistened with petrol.

Types Of Oil Seal NBC Offer

Choosing the right oil seal

silicone rubber gasket. This resistance makes them suitable for use in industries where exposure to harsh chemicals is common, such as in the chemical processing, pharmaceutical, and food and beverage industries. The inert nature of silicone rubber also prevents it from reacting with the substances it comes into contact with, ensuring a long-lasting and reliable seal.

Oil seals are used in a great many devices for steel production equipment.

Figure 7 shows the places where each seal type is used in a rolling mill.

They engage in continuous research and development to enhance spark plug technology They engage in continuous research and development to enhance spark plug technology

They engage in continuous research and development to enhance spark plug technology They engage in continuous research and development to enhance spark plug technology For example, oil seals made from high-quality materials such as silicone are likely to be more expensive than seals made from cheaper materials For example, oil seals made from high-quality materials such as silicone are likely to be more expensive than seals made from cheaper materials

For example, oil seals made from high-quality materials such as silicone are likely to be more expensive than seals made from cheaper materials For example, oil seals made from high-quality materials such as silicone are likely to be more expensive than seals made from cheaper materials