composite grating

Links

-

4. Capacity to Handle Heavy Materials Leather is known for its resistance and thickness, which can be a challenge for many sewing machines. Manual leather sewing machines are often designed with robust mechanisms that can handle the heft of leather without jamming or breaking needles. This capability makes them ideal for crafting a wide range of leather products.

-

2. Better Stitch Quality The chain stitch produced is often more aesthetically pleasing and provides a flatter finish compared to traditional stitches, enhancing the overall appearance of the garment.

-

The applications of the walking needle sewing machine are vast and diverse. In the fashion industry, it is commonly used for constructing garments, as it allows for precise seams and finishes. Craftspeople appreciate its utility in creating bags, upholstery, and home decor items. Quilters especially favor walking needle machines for their ability to handle layered fabrics without compromising accuracy.

-

Furthermore, the community surrounding sewing is vibrant and supportive. Online forums and local sewing groups are filled with enthusiasts sharing tips, patterns, and inspiration. Many often share their projects made with Zig Zag machines, showcasing the machine's capabilities and inspiring others on their sewing journey. This camaraderie fosters learning and development in skills while celebrating the art of sewing.

- - Hems finish the edges of your fabric and can be done by folding the fabric twice (about 1/4 inch each time) and sewing along the edge.

-

The bobbin shuttle hook is an essential part of sewing machines, particularly in the context of industrial and domestic textile manufacturing. Understanding its function and significance can provide valuable insights into the evolution of sewing technology and the precision required in the art of stitching.

-

One of the primary functions of an overlocker is to finish raw edges of fabric. This is particularly useful for knit fabrics, which tend to stretch and curl. Overlocking edges with a serger provides a professional finish that is both durable and visually appealing. The machine utilizes multiple threads to create a strong seam, making it ideal for garments that require flexibility, such as t-shirts, leggings, and activewear.

-

Sewing, a craft steeped in tradition and art, has evolved over centuries into a diverse array of specialized techniques. Each method offers unique possibilities, allowing artisans to express creativity and precision. The term special sewing encompasses a range of advanced techniques designed for various applications, from bespoke garments to intricate home decor. In this article, we will delve into the world of special sewing, exploring its techniques, tools, and the joy it brings to both hobbyists and professionals.

-

When it comes to sewing, having the right machine is crucial. For both beginners and experienced seamstresses alike, a heavy-duty home sewing machine is an invaluable asset that can elevate your craft to new heights. These machines are specifically designed to handle a variety of fabrics and projects, making them a popular choice for anyone looking to tackle larger or more complex sewing tasks.

-

Advantages

The Impact on the Textile Industry

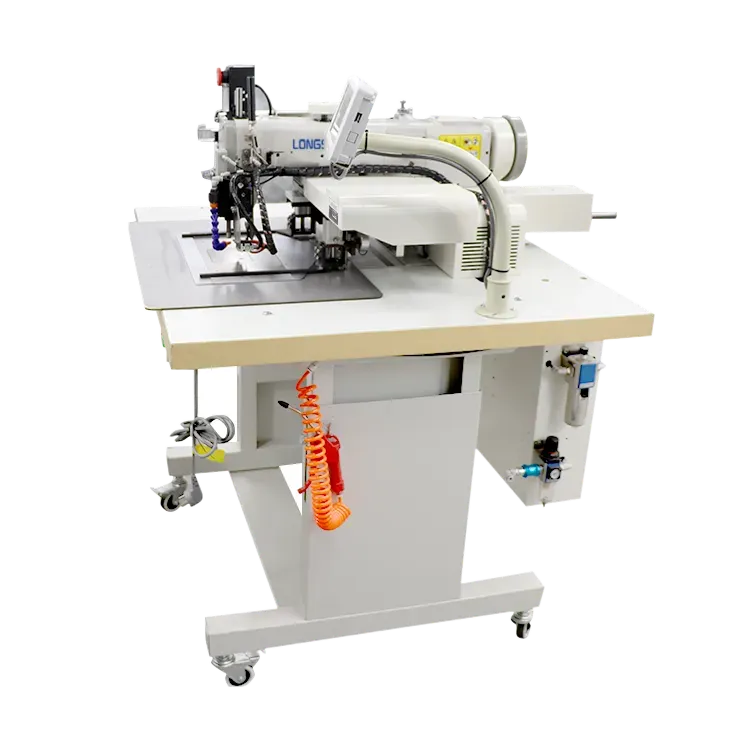

The double needle walking foot industrial sewing machine is a remarkable piece of equipment that has gained prominence in the textile and garment manufacturing sector. This machine stands out for its ability to sew two parallel lines of stitches simultaneously, which is ideal for various applications, such as quilting, garment construction, and upholstery work. Here, we will explore the mechanics, benefits, and applications of this versatile industrial sewing machine.

Self-threading sewing machines represent a fantastic advancement in the world of sewing, making it easier and more enjoyable for users of all skill levels. By reducing the difficulty of threading and enhancing efficiency, these machines have transformed how individuals approach their sewing projects. Whether you’re a beginner or a seasoned pro, investing in a self-threading sewing machine can streamline your workflow and elevate your crafting experience. So, explore the options and find the perfect machine for you today!

Finally, the environmental impact of auto sewing is worth noting. With increased efficiency and reduced fabric waste, automated systems can contribute positively to sustainability efforts in the textile sector. As the demand for eco-friendly practices rises among consumers, companies that embrace auto sewing technology may also align better with green initiatives and enhance their brand appeal.

In conclusion, sofa upholstery sewing machines play an integral role in enhancing the quality and efficiency of furniture design. Their ability to work with heavy fabrics, execute intricate stitching, and streamline production processes makes them an essential tool for upholstery professionals. Furthermore, the technological advancements in sewing machines contribute to sustainability efforts within the industry. As furniture designs continue to evolve, the importance of specialized sewing machines will only grow, ensuring that the artistry of upholstery remains at the forefront of furniture manufacturing.

The Significance of a Threader for Needlework A Seamstress's Best Friend

While both spent $1000 over six years, Jane had the advantage of a machine that could handle more complex projects, ensuring she didn’t turn down work or compromise on quality.

2. Use the Right Tools Invest in high-quality needles and thread suitable for the fabric being used. The right tools make a significant difference in the outcome and efficiency of the work.

The primary advantage of using a walking foot is the improved fabric control it provides. When working with thick fabrics, the risk of uneven sewing increases due to the bulk of the material. A walking foot helps to maintain an even stitch length, minimizing the risk of puckering or distortion that can occur when multiple layers are sewn together.

2. Local Sewing Shops Many local fabric and sewing supply stores offer sales on machinery, especially if they are introducing new models. Shopping local not only supports your community but also provides the opportunity to test machines in person.

double sewing machine. The two spools of thread can be easily switched out to accommodate different colors or types of thread, giving you even more flexibility in your sewing projects.

heavy duty bag making machine. They are designed to withstand the rigors of continuous use in demanding industrial environments, ensuring dependable performance and minimal downtime. This durability not only reduces maintenance and repair costs but also prolongs the lifespan of the machine, providing a good return on investment for manufacturers.

Automatic button sewing machines are not limited to traditional clothing applications. They can also be utilized in creating custom crafts, upholstery work, and even in the production of accessories. With the ability to handle various button sizes and styles, from basic plastic to decorative metal buttons, these machines can cater to a wide range of projects.

Moreover, the integration of technology into these machines often includes features like computerized stitching, real-time monitoring, and customizable settings. Users can adjust parameters such as stitch length and width, and some machines even come with Wi-Fi connectivity that allows for software updates and pattern downloads directly from online resources. This level of customization ensures that users can adapt to various projects and materials, promoting creativity and innovation in design.

The Art of Single Needle Stitch A Timeless Technique

Applications of Lock Stitch

Moreover, weather resistance is paramount in tent making. The stitching must be strong and secure to prevent leaks during rainy days. Consequently, the sewing machine should have options for various types of stitches, including straight, zigzag, and reinforced stitching.

In the modern automotive industry, where precision and efficiency are paramount, the role of specialized machinery cannot be overstated. Among these, automotive sewing machines stand out as critical tools in the production of vehicle interiors, particularly in the crafting of seats, upholstery, and various textile components. This article explores the evolution, functionality, and significance of automotive sewing machines in the automotive sector.

D. Outdoor Gear and Bags:

Readers will find inspiration for sewing outdoor gear like backpacks, tents, and camping accessories that require the durability and strength provided by heavy duty machines.

Moreover, with the rise of sustainability in fashion, automatic button sewing machines can play a significant role. By enhancing efficiency and reducing waste, they allow businesses to operate more sustainably. For instance, fewer mistakes in button placement mean less fabric scrapping and reduced resource consumption overall. This aligns with the growing consumer demand for eco-friendly production practices, ultimately benefiting the environment.

As the name suggests, a double needle long arm sewing machine features two needles that allow for the simultaneous sewing of two parallel lines of stitches. This capability is particularly useful for decorative stitching or creating intricate patterns, often seen in quilting projects. The long arm design provides extra workspace, making it ideal for handling larger fabrics or bulky quilts without the headache of fabric bunching or wrinkling.

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality cnc sewing machine upholstery.

cnc sewing machine upholstery. Sewing Through Leather Techniques, Tools, and Tips

When your machine is not in use, you should keep it covered or packed away to prolong its lifespan of the machine. You will also want to have an authorized dealer service your machine yearly. And of course, always check and follow the manufacturer's instructions in your manual to ensure that you maintain your machine according to manufacturer specifications.