filter vessels

Links

-

Wall Mounted Control Box - Reflective floor tape is a highly visible material that is applied to floors to create a safe and visible pathway. It consists of a layer of reflective material, usually in the form of beads or microprisms, which reflects light in all directions. This makes it highly visible even in low-light conditions, such as at night or during foggy weather.

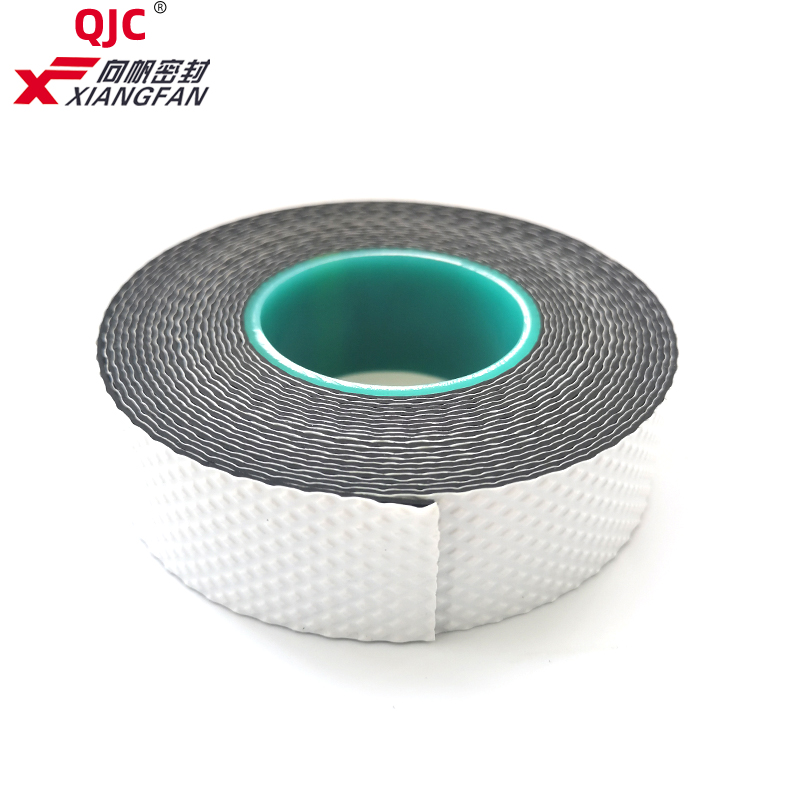

butyl rubber tape manufacturers. Their butyl rubber tape is known for its high strength and resistance to oil, fuel, and other harsh chemicals. It is commonly used for sealing body panels, windows, and other components on race cars.

Polyethylene Tape, or PE Tape, is a type of adhesive tape made from polyethylene, a durable and versatile thermoplastic polymer. It finds a wide range of applications due to its various properties and benefits.

Butyl rubber tape is also incredibly flexible and easy to apply. It can be cut to size and shaped to fit various contours and surfaces. This adaptability makes it a favorite among DIY enthusiasts and professionals alike. Applying the tape typically requires no special tools; even those with minimal experience can achieve a reliable seal by simply cleaning the surface and pressing the tape into place.

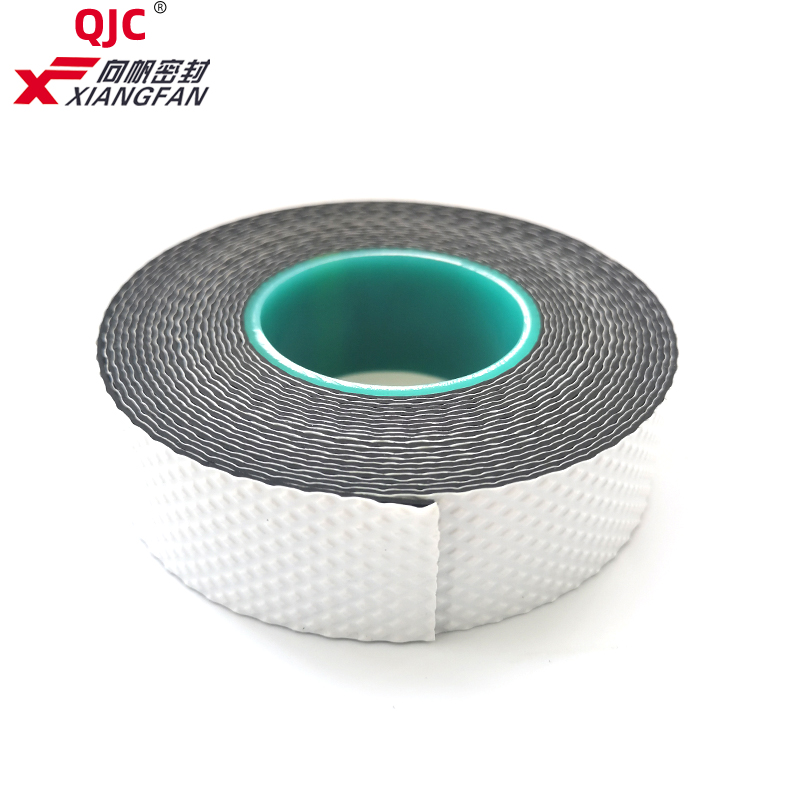

One of the key advantages of using 130C linerless rubber splicing tape is its ability to provide a tight and secure seal. This makes it perfect for applications where a leak-proof bond is essential, such as in plumbing or automotive industries. The tape is also resistant to chemicals and oils, further enhancing its durability and reliability.

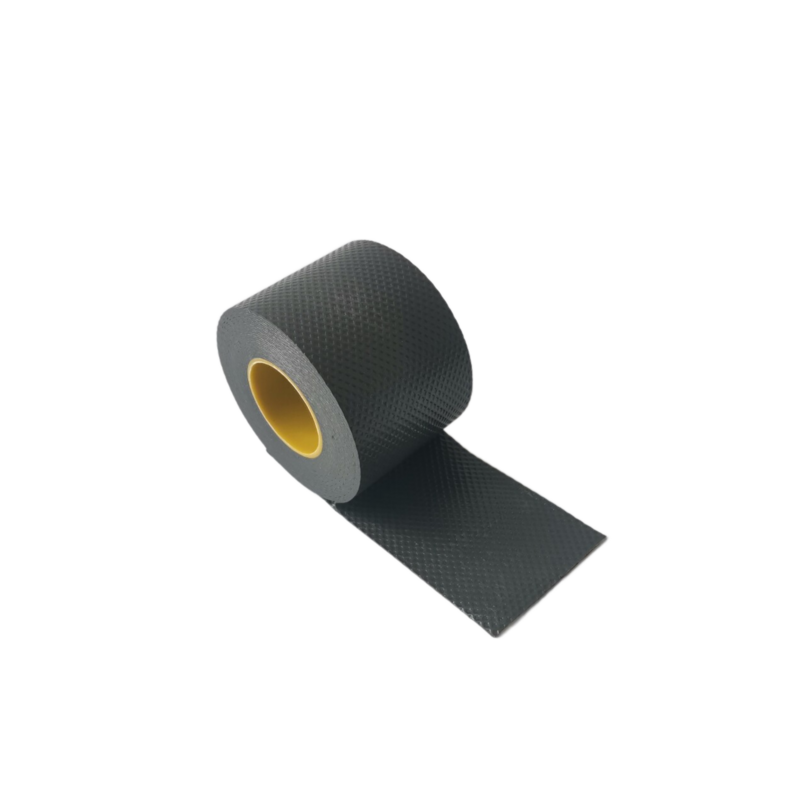

130c linerless rubber splicing tape

butyl tape rubber.

Types of Control Boxes

Material: Self-fusing silicone rubber

Properties of Butyl Rubber

Moreover, butyl rubber tape is non-toxic and safe for use in various applications, including food-related contexts. This makes it a great choice for sealing appliances, packaging, or other areas where food safety is a concern. Its versatility extends to a range of industries, including automotive, construction, electronics, and more.

Applications of Red and White Floor Marking Tape

(2) Withstand voltage 27KV / mm; What are the advantages of silicone rubber self-adhesive tape

Thickness

black floor marking tape. It can be used to section off pet areas, create play zones for children, or even outline a home gym setup. Its durability and easy application make it an ideal solution for temporary or permanent floor markings.

black floor marking tape. It can be used to section off pet areas, create play zones for children, or even outline a home gym setup. Its durability and easy application make it an ideal solution for temporary or permanent floor markings. Peel off the plastic backing and wrap it around the object that needs repairing. Make sure you lap it over itself three to five times to make it secure

Water and Solvent Based Acrylics

When designing a control box, you should not take it lightly irrespective of the simplicity of the box you intend to build. Here are three factors that will help you design a functional, reliable, and safe control box.

Butyl rubber, a synthetic rubber derived from isobutylene and isoprene, is known for its excellent impermeability to gases and moisture. This unique property makes it an ideal choice for various applications across multiple industries. Butyl rubber rolls, specifically, are widely utilized due to their versatility and high performance.

It also has heat resistance, which makes it suitable for applications requiring exposure to moderate heat levels It also has heat resistance, which makes it suitable for applications requiring exposure to moderate heat levels

It also has heat resistance, which makes it suitable for applications requiring exposure to moderate heat levels It also has heat resistance, which makes it suitable for applications requiring exposure to moderate heat levels pvc electrical tape.

pvc electrical tape.  It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run.

pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run. The rubber adhesive used in Polyethylene Rubber Tape offers several advantages that contribute to its performance and effectiveness.