Since most of the material in your aluminum fence is made up of this abundant metal, you may be thinking, why is it so expensive in the first place? After all, isn’t most of it recycled aluminum anyway?

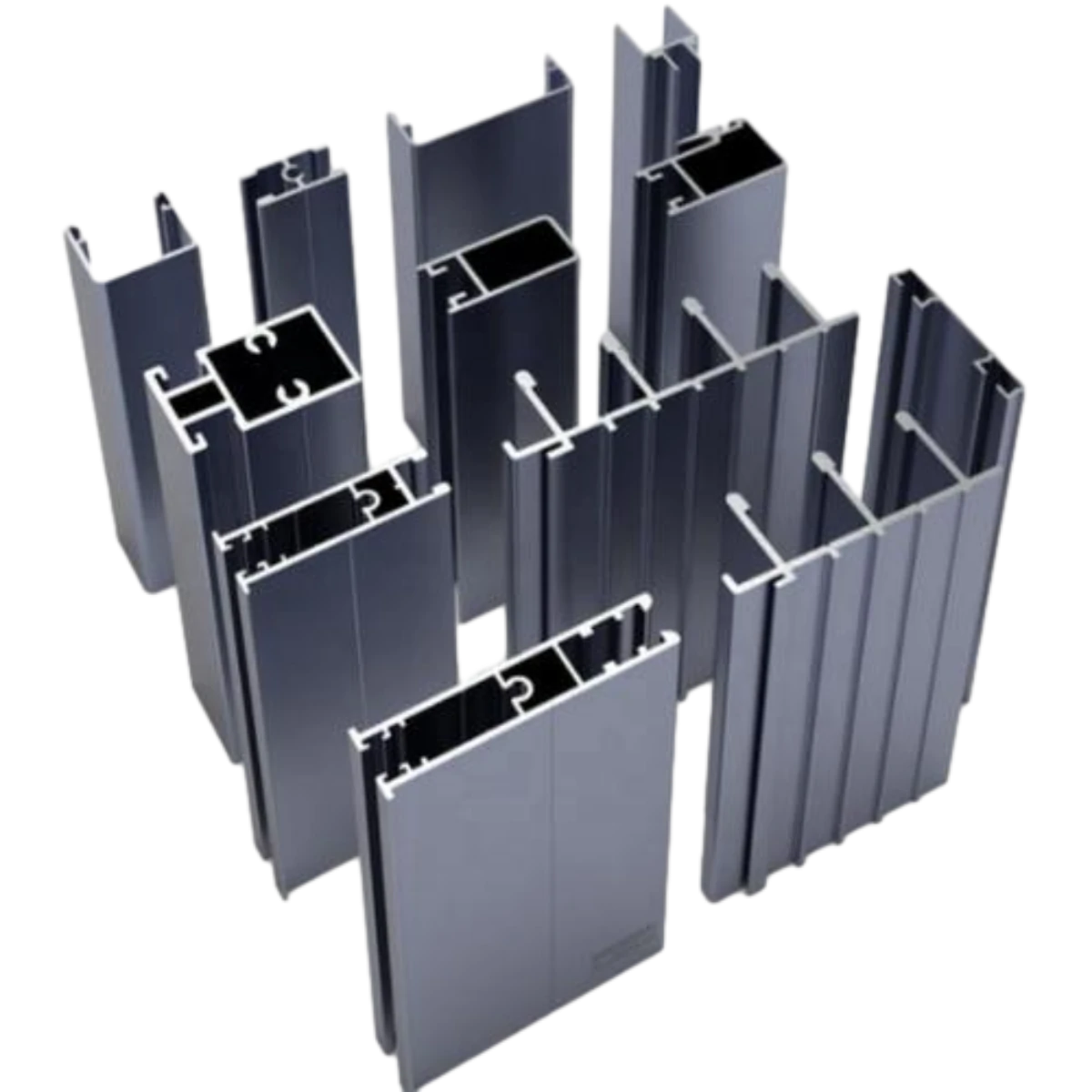

In essence, it is the natural finish the extruded aluminum profiles have the moment they emerge from the extruder die.

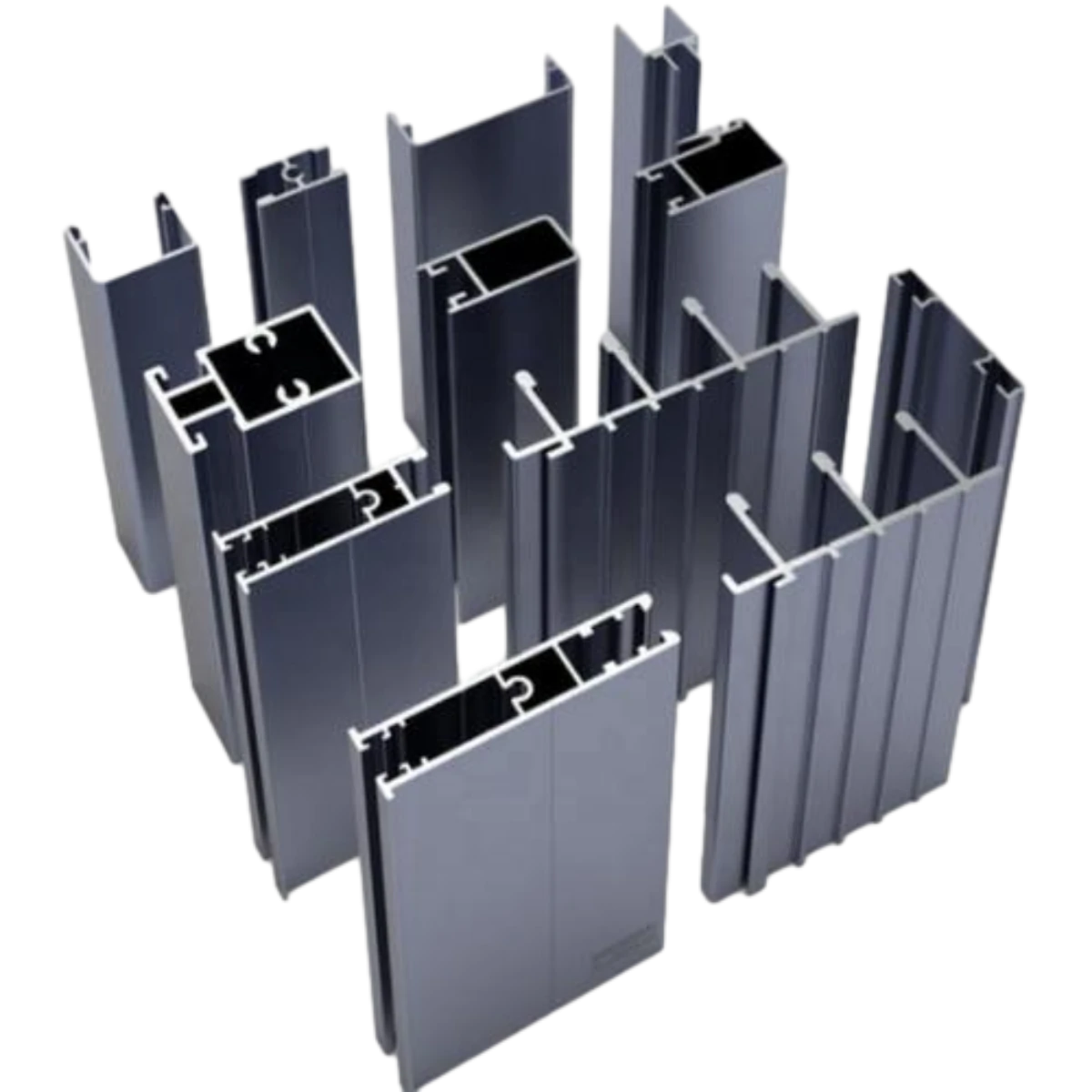

Direct Extrusion

As the emphasis on sustainable design grows, stainless steel rises to the forefront as an eco-friendly option. Its longevity means that fewer replacements are needed over time, reducing waste. Moreover, stainless steel is 100% recyclable, contributing to a lower environmental impact compared to materials that may require more resources to produce and dispose of.

Decorative items, often seen as mere embellishments, play a pivotal role in defining the character and ambiance of our living spaces. From the charming knick-knacks on a shelf to the statement art pieces adorning our walls, decorative items are essential in creating an environment that reflects our personal style and enhances our daily lives.

Sliding doors are an attractive and functional addition to any home, offering a seamless transition between indoor and outdoor spaces. However, like all moving parts, the rollers on sliding doors can wear out or become misaligned over time. If you're experiencing difficulty in opening or closing your sliding door, it might be time to adjust the rollers. In this guide, we will explore the steps necessary to adjust sliding door rollers, ensuring smooth operation and extending the lifespan of your door.

Also known as Hardcoat, it is relatively thick and denser than both chromic and sulfuric acid anodize.

After weighing the factors like aesthetic appeal, cost considerations, durability, security, and maintenance, it’s clear that wrought iron fencing rises to the top. It offers unparalleled beauty, stands the test of time, and brings a level of security that few other materials can match.

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.

aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection. In addition to their strength, metal taps are aesthetically pleasing, often featuring polished finishes that can enhance the overall look of fixtures in homes and commercial spaces. They are also typically more resistant to wear and tear, which contributes to a longer lifespan compared to plastic taps.