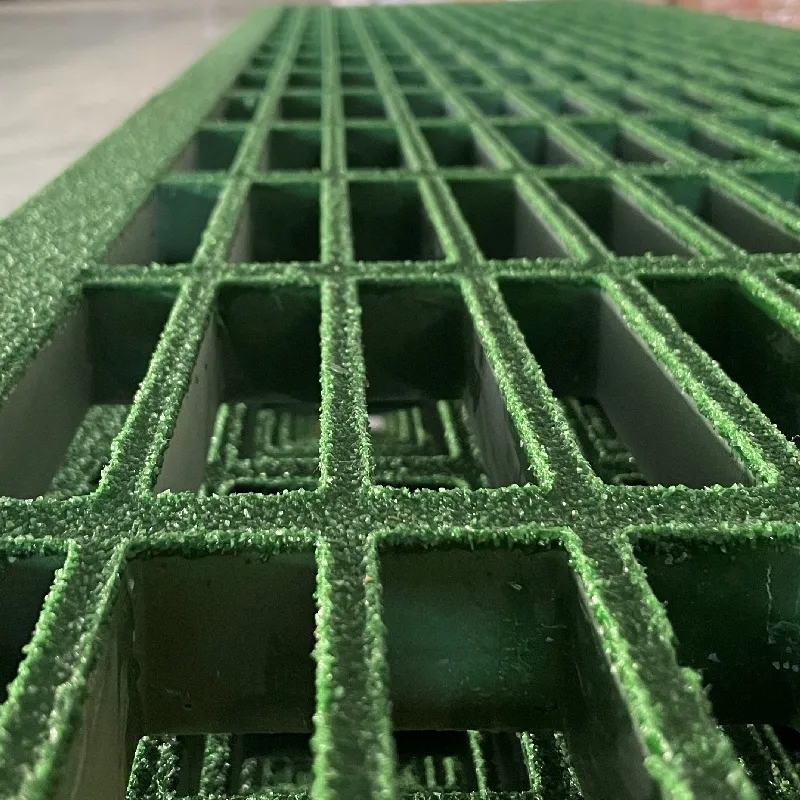

swimming pool grating

Links

-

Materials: Made from wear-resistant materials like high-chrome alloys or stainless steel.

-

Function: Bearing assemblies support the pump shaft and ensure smooth operation.

-

-

Understanding the Role of Propeller Pumps in Various Applications

-

In the world of fluid handling, the choice between a vertical inline pump and a centrifugal pump can significantly impact system efficiency, maintenance, and overall performance. Both types of pumps are widely used in various industries, but they have distinct characteristics that make them suitable for different applications.

-

Sewage pump impellers play a crucial role in the effective management of wastewater systems

. These specialized components are designed to transport sewage and wastewater from lower to higher elevations, ensuring that sewage is directed away from residential and commercial properties to treatment facilities. Understanding the functionality and types of sewage pump impellers can help in selecting the right pump for specific applications.

-

6. Consult with Experts

-

The performance and efficiency of a horizontal centrifugal slurry pump are crucial for ensuring its optimal operation in various industrial applications. Accurate assessment of these factors involves detailed testing of flow rate, head, and efficiency. This article explores the essential performance indicators and how they are measured to ensure that the centrifugal slurry pump operates according to expected standards.

-

Horizontal Inline Centrifugal Pumps: Versatility and Reliability

-

Selecting the appropriate slurry pump model quickly involves understanding your application's specific requirements and matching them with the pump's capabilities.

-

- Mechanical Seals: Provide a tight seal and reduce leakage.

-

-

- Throat Bush: Protects the area around the impeller eye where the slurry first enters.

-

Efficiency Testing for AH Slurry Pump Parts

-

-

Maintenance of sewage pump impellers is also vital for ensuring their longevity and functionality. Regular inspection can help identify wear or damage, and timely replacement of worn-out impellers can prevent pump failures and costly repairs. Moreover, keeping the impeller clean from debris buildup ensures optimal performance.

-

-

-

6. Bearing Assemblies

-

Enhancing Durability with High Pressure Vertical Pumps

-

-

Slurry pumps are essential components in various industries, particularly in mining, mineral processing, and wastewater treatment. They are specifically designed to handle abrasive and viscous materials, which makes understanding their components crucial for optimal performance and longevity. One of the most critical aspects of a slurry pump is its wet end, which refers to the parts that come into direct contact with the slurry. In this article, we will explore the key wet end parts of a slurry pump, their functions, and their importance.

-

8. Pump Backplate

-

4. Suction and Discharge Flanges

-

-

Flow Rate Measurement in Horizontal Centrifugal Slurry Pump

-

Horizontal inline centrifugal pumps are among the most versatile pumps available, widely used across industries for their reliability and ease of maintenance. Unlike vertical pumps, these pumps are installed horizontally, which typically makes them easier to service and maintain. The horizontal design allows for more straightforward access to the pump’s internal components, which can be a significant advantage in applications where regular maintenance is required. Additionally, horizontal inline centrifugal pumps are capable of handling a wide range of fluid viscosities and flow rates, making them suitable for various industrial processes. Their versatility and robust construction make them a popular choice for many fluid handling applications.

-

In quarrying, the separation of sand and gravel is a vital process that requires reliable equipment. Horizontal slurry pumps are particularly well-suited for this task, as they can efficiently handle the slurry mixture of sand, gravel, and water. The centrifugal slurry pump design ensures that these materials are separated and transported to their respective storage or processing areas with minimal energy consumption. By utilizing OEM horizontal slurry pumps, quarry operations can streamline their processes, reduce operational costs, and improve the quality of the final product. The durability and efficiency of these pumps make them a cost-effective solution for handling the abrasive and coarse materials commonly found in quarries.

-

In firefighting systems, propeller pumps also play a crucial role. They provide the necessary pressure and volume of water needed to combat fires effectively. Their capability to move large quantities of water quickly makes them a reliable choice for fire departments, particularly in high-risk areas where rapid response is critical.

-

Understanding Sewage Pump Impellers A Key Component in Waste Management

-

-

- Reach out to the pump manufacturer’s technical support team for assistance in confirming your selection.

-

- Concentration: Measure the percentage of solids by weight or volume in the slurry.

-

-

-

-

-

2. Liners

-

-

b. NPSH (Net Positive Suction Head):

-

The Importance of Wholesale Slurry Pumps in Industrial Applications

-

-

Function: Seals prevent slurry from leaking out of the pump and protect the internal components.

-

Wear Factors: Bearings can wear out due to the mechanical loads and need periodic lubrication and replacement.

-

- Consider the type of seal (e.g., mechanical seals, packing) based on the slurry's properties and operating conditions.

-

-

- Mechanical Seals: Provide a tight seal and reduce leakage.

-

When designing pumps for deep pit applications, structural engineering plays a crucial role in ensuring reliability and efficiency. The vertical orientation of these pumps must be supported by a sturdy framework that can handle the stresses associated with deep pit operations. This includes ensuring that the pump’s foundation is secure and that the piping system is properly aligned to prevent vibrations and other operational issues. Additionally, the materials used in constructing vertical multistage centrifugal pumps must be carefully selected to resist corrosion and wear. By considering these structural engineering factors, designers can optimize the performance and durability of vertical slurry pumps in deep pit applications.

-

-

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire