chs tube

Links

-

- Hardware

- 。、,。,。

-

Knowledge

- Overall, when it comes to aluminium window wheels, price is an important factor to consider. By doing some research, comparing prices, and weighing the cost against the quality and durability of the wheels, you can make an informed decision that will provide long-term benefits for your windows. Remember to also consider the warranty and customer service provided by the manufacturer to ensure a positive purchasing experience.

- The first step in fixing your screen door wheels is to remove the old ones. To do this, follow these instructions

-

-

At its core, basketball is played on a rectangular court, where two teams of five players each attempt to score points by shooting a ball through the opposing team’s hoop. The rules are straightforward dribble the ball, pass it to teammates, and score. Yet, the beauty of the game lies in its complexity. Players must develop a range of skills, from dribbling and shooting to defensive tactics and teamwork, to succeed. The strategic nature of the sport keeps both players and fans engaged, constantly analyzing plays and anticipating movements on the court.

How to choose aluminium windows?

Nonetheless, typical aluminum profiles for windows and doors can last for more than 10 years.

1.0mm and above, or customized - In the realm of home improvement and architecture, the choice of windows can significantly impact a building's aesthetic and energy efficiency. One innovative solution that has gained popularity in recent years is aluminium windows with a slim profile. These windows offer a sleek and modern look while also providing excellent thermal performance and durability.

Their corrosion resistance properties make them ideal for withstanding harsh weather conditions, ensuring that windows maintain their appearance and functionality over time. Additionally, aluminum profiles provide design flexibility, allowing for the creation of various window styles and configurations. Their easy installation and low maintenance requirements make them a practical choice for both residential and commercial applications.Moreover, aluminium profiles can be customized to incorporate thermal breaks, which enhance energy efficiency by reducing heat transfer between the interior and exterior of a building. This feature helps in maintaining comfortable indoor temperatures and reducing energy consumption for heating and cooling.

- In conclusion, changing rollers on a sliding screen door is a relatively simple process that can be done with basic tools and a little bit of know-how. By following the steps outlined in this article, you can ensure that your sliding screen door operates smoothly and efficiently for years to come. So if you notice that your screen door is sticking or not sliding properly, don't hesitate to change the rollers and restore its functionality.

Another advantage of sliding cabinet rollers is their ease of use. With just a gentle push or pull, the shelves slide in and out smoothly, allowing you to easily access items without any hassle. This can be particularly helpful for individuals with limited mobility or strength, as it eliminates the need to reach or bend to retrieve items from the back of the cabinet. Additionally, the smooth sliding motion of the rollers helps protect delicate items from being jostled or knocked over, ensuring that your cabinet contents remain safe and secure.

- Decorative cast iron panels were particularly popular during the Victorian era, adorning everything from building facades to household furnishings. They were often adorned with motifs inspired by nature, such as floral arrangements, animal figures, or geometric shapes, reflecting the prevalent styles and tastes of the time. Each panel tells a story, capturing the spirit and essence of the era in which it was created.

Once you’ve removed the dirt from your fence, use a stiff wire brush to get rid of any loose paint or rust spots. If that doesn’t do the trick, use some fine sandpaper to remove any remaining rust.

Make sure your fence is completely dry after this step; whether you want to leave it to air dry in the sun or thoroughly dry it with a towel.- Moreover, sliding screen wheels offer versatility in design

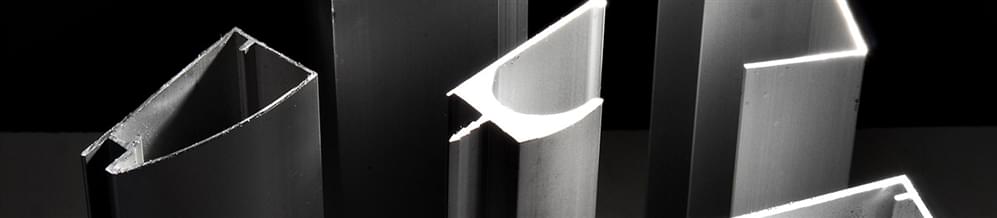

What are aluminum profiles and their uses?

- Another benefit of steel door rollers is their low maintenance requirements. Unlike other types of rollers, which may require regular lubrication or cleaning, steel rollers are designed to be low-maintenance. This means that you can enjoy hassle-free operation without having to worry about constant upkeep.

- The 600mm pull handle, a common fixture in modern architecture and industrial settings, has become a popular choice due to its robust design and functionality

- Another advantage of stainless steel barn door handles is their sleek and modern design. These handles come in a variety of styles and finishes, allowing you to find the perfect match for your home decor. From classic brushed stainless steel to modern polished chrome, there's a handle to suit every taste. Plus, the minimalist design of these handles complements the rustic charm of barn doors, creating a cohesive and stylish look throughout your home.

In addition to their aesthetic and durability benefits, cast iron picket fences provide a sense of security. Their strength deters intruders and protects children and pets within the yard. The height of the fence can be customized to meet personal security needs while still allowing for visibility. Unlike solid walls, cast iron fencing provides an open view, allowing homeowners to keep an eye on their surroundings and enhance neighborhood safety.

- Wrought iron is so long-lasting that it has earned the nickname 100-year fence. This is due to the material's ability to withstand severe weather conditions.

- One of the key benefits of sliding screen door runners is that they help to reduce friction between the door and the track. This allows the door to slide smoothly and effortlessly, making it much easier to open and close. Properly functioning runners can also help to extend the life of the door and prevent unnecessary wear and tear.

- Utilize Scrap Metal Services: Many scrap metal dealers and recycling centers will accept wrought iron because it can be melted down and reused in various applications. It’s important to call ahead and confirm that they accept wrought iron, as this will save time and ensure that the material is disposed of responsibly.

- Lastly, double-check all screws and connections to ensure they are tight and secure. A properly installed wheel replacement will not only restore the functionality of your sliding screen door but also prolong its lifespan.

The coating film should be uniform and tidy, Wrinkles, cracks, bubbles, flow marks, inclusions, stickiness and peeling off of the coating film are not allowed. However, the profile ends allow for partial filmlessness.

Both paint and powder coatings are common solutions, though powder coatings can’t be touched up on site when they chip, which makes them less practical for long term maintenance. we typically hot dip galvanize our wrought iron, which adds a zinc coating to the metal, protecting it from oxidation. We then prime and paint over it for finishing.

As a leading door and window hardware company, we take pride in our commitment to quality, innovation, and customer satisfaction. Our team of experts is dedicated to helping you find the ideal solutions for your home improvement projects, providing personalized assistance every step of the way.- Moreover, education about lock usage is as critical as having them. Family members should be taught how to properly lock doors and windows, and encouraged to adopt habits like double-checking before leaving or retiring for the night.

Recycling Wrought Iron

While at it, you should be careful not to overheat it to a melting point, often about 1200° F. An ideal heating point should be approximately 900° F.

Taps serve as control mechanisms that regulate the flow of liquids or gases. They are used in various settings, including kitchens, bathrooms, laboratories, and even manufacturing plants. While the primary function of a tap is straightforward—either to allow or restrict flow—the materials from which they are made greatly influence their performance, durability, and suitability for specific environments.

- Decorative fences made from ornamental iron are usually mass produced. Therefore, they have a more uniform look than their handcrafted counterparts.

- In the realm of home furnishings, the sliding door often takes a backseat to its more flamboyant counterparts. Yet, it is within this unassuming piece that we find an orchestra of functionality and design epitomized by the humble track wheels. These diminutive components are the silent symphony that enables the smooth glide of sliding doors, turning an otherwise cumbersome transition into a fluid dance of wood and metal.

-

For Mill Finish

- In a world increasingly driven by technology, these humble household essentials remind us of the importance of simplicity and functionality. The cosulet, with its nostalgic charm, and the bulb, symbolizing progress, coexist harmoniously in our lives, each contributing its unique essence. As we continue to innovate and advance, let us not forget the value these everyday objects hold and the roles they play in shaping our daily experiences.

-

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire