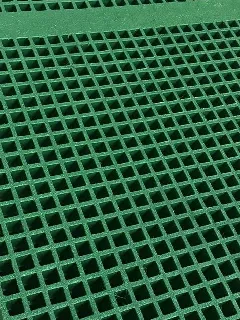

ZJ Composites frp division bar

-

One of the primary applications of floor metal grating is in industrial settings, where it is often used for walkways, platforms, and stairways

. The open design of the grating minimizes the accumulation of debris and allows for effective drainage, which is crucial in areas where liquids can spill. This feature not only enhances safety by reducing slip hazards but also ensures compliance with safety regulations....

Links

-

2. Nausea Just like humans, dogs may drool when they feel nauseous. This can occur due to motion sickness, changes in diet, or gastrointestinal issues.

-

1. Supports Immune Function Multivitamins often contain essential nutrients such as vitamins A, C, and E, which are known to enhance the immune system. A strong immune system helps puppies fend off illnesses and supports overall health, especially during their formative months when they are most vulnerable.

- - Nasal discharge Mucus may be present, often accompanying the cough.

-

Benefits of Supplementing with Multivitamins

-

2. Regular Hoof Care Schedule regular hoof trimming and inspections by a farrier. This helps identify early signs of thrush or other hoof problems before they become severe.

-

Safe Medications for Dogs A Comprehensive Guide for Pet Owners

-

When administering worming medicine, ensure that you strictly follow the instructions provided by your veterinarian or included with the product. Dosage is usually determined by the puppy’s weight, so it’s important to obtain an accurate measurement before treatment.

-

Considering the heightened nutritional needs during lactation, many pet owners opt to provide nursing dog vitamins to support their mothers’ health. These supplements are specifically designed to fill any dietary gaps and ensure that the mother dog receives the necessary nutrients in adequate amounts.

-

In recent years, the realm of veterinary science has expanded to include various forms of alternative medicine, appealing to pet owners looking for holistic approaches to their dogs' health. As the desire for natural and non-invasive treatments grows, an increasing number of canines are benefiting from modalities such as acupuncture, herbal medicine, chiropractic care, and homeopathy. This article aims to shed light on these alternative treatments, their benefits, and considerations for implementation in canine care.

-

While treatment is important, prevention is the most effective strategy to combat the spread of swine flu. Vaccination is the cornerstone of prevention efforts. The annual flu vaccine is updated each year to protect against the most prevalent strains, including H1N1. Health authorities recommend vaccination for everyone aged six months and older, especially for high-risk groups such as pregnant women, young children, and individuals with chronic health conditions.

-

Amoxicillin injection serves as an essential tool in treating various bacterial infections, particularly in acute or severe cases. Its rapid action, high bioavailability, and effectiveness make it a preferred choice in many clinical scenarios. However, careful consideration of allergies, potential interactions, and the risk of antibiotic resistance is vital in ensuring its safe and effective use. By adhering to appropriate prescribing practices, healthcare providers can harness the full potential of amoxicillin injection in the fight against bacterial infections.

-

Another aspect to consider is the importance of hydration while using expectorants. Drinking plenty of fluids is essential to maximize the effectiveness of these medications. Water intake helps to further thin mucus, enhancing the expectorant's ability to ease its expulsion from the body. Thus, patients are often advised to maintain adequate hydration throughout their treatment, which supports overall respiratory health and helps in recovery from infections.

-

Understanding Pneumonia in Cattle

-

Nutritional issues are another contributor. Abrupt changes in diet, especially the introduction of grain-heavy feeds, can upset the delicate balance of microbes in a sheep's rumen and lead to diarrhea. Overeating or consuming spoiled feed can also result in gastrointestinal upset. Moreover, environmental factors such as wet, muddy living conditions can increase the incidence of intestinal infections, further predisposing sheep to diarrhea.

-

When it comes to maintaining the health and well-being of equines, one of the most critical aspects is managing parasites. Horses are susceptible to various internal and external parasites, including worms, bots, and lice, which can lead to significant health issues if left untreated. Understanding the importance of effective horse medicine for parasites is essential for any horse owner or caregiver.

-

Before diving into treatment options, it's crucial to identify when your dog has a sore paw. Common signs include limping, favoring one paw over the others, reluctance to walk, licking or biting at the paw area, and swelling or redness. If you notice these symptoms, it’s important to examine your dog's paws closely. Look for any visible injuries, such as cuts, blisters, or foreign objects lodged between the pads.

-

3. Anti-nausea Medications Veterinarians may prescribe medications like metoclopramide or ondansetron, which can effectively alleviate nausea. Never give your dog human medications without consulting a vet.

-

In addition to medical treatments, you can promote your dog's digestive health through diet and lifestyle adjustments. Here are some tips

-

2. Ondansetron Originally developed for humans undergoing chemotherapy, ondansetron can also be effective for dogs. It works by blocking serotonin receptors in the brain that lead to nausea and vomiting. This medication is typically used in more severe cases, such as after surgery or during chemotherapy.

-

Importance of Prompt Treatment

-

Preventing lice infestations is as crucial as treating them. Maintaining proper hygiene in housing facilities, providing appropriate nutrition, and monitoring cattle for signs of pests can help minimize the risk of an infestation. Regular veterinary check-ups can also help catch and address lice problems early.

-

The 2023 edition, witnessed around 500 exhibiting companies from 50 countries, 17,500 sqm gross and 10,080 expected visitors. The show had an enriched conference program covering dairy, fish, poultry, eggs, cattle, calves, goat, and camels. More than 37 sessions, presentations and panel discussions delved into recent industry trends, challenges, and opportunities, providing invaluable insights for all attendees, in both the animal livestock production and the arable and controlled environment agriculture industry. One third of the visitors came from the UAE, with countries like Egypt, Iraq, Iran, Pakistan and Saudi Arabia ranking on top right after. At VIV MEA, suppliers and buyers from all the segments of the Feed to food chain are represented. This includes feed (ingredients) and animal health, animal husbandry, equipment for breeding, farming, slaughtering, processing and much more.

-

Amoxicillin injection is primarily utilized to treat serious bacterial infections. It is effective against a broad range of pathogens, including Streptococcus pneumoniae, Staphylococcus aureus, and Escherichia coli. Common indications for its use include

-

For chronic conditions like arthritis, weight management and physical therapy are essential components of treatment. Keeping your dog at a healthy weight reduces strain on the joints, while physical therapy can aid in rehabilitation and improve flexibility and strength.

-

2. Dietary Adjustments In some cases, changing a dog’s diet can alleviate symptoms of nausea. A bland diet, consisting of boiled chicken and rice, is often recommended temporarily until the nausea subsides. There are also specialized prescription diets that are easier on a dog's digestive system.

-

2. Infections Bacterial infections, such as salmonellosis, or viral infections like equine coronavirus, can cause significant gastrointestinal upset. Parasitic infections from worms can also lead to diarrhea.

-

In conclusion, expectorants play a vital role in respiratory care, primarily through their active ingredient, guaifenesin, and other compounds. Depending on individual patient needs, different formulations may be appropriate. Awareness and understanding of these active ingredients can empower patients and healthcare providers in making informed choices when addressing cough and mucus-related conditions. As always, consultations with healthcare professionals are crucial to ensure safe and effective treatment regimens tailored to individual health needs.

-

4. Do Not Self-Medicate While it might be tempting to use human medications to alleviate your pet's discomfort, many human drugs are toxic to dogs. Drugs like ibuprofen, acetaminophen, and other NSAIDs specifically designed for humans can be severely harmful and should not be given to dogs without veterinary approval.

-

Understanding Stiffness in Horses

-

As responsible dog owners, it is crucial to stay informed about your pet’s health. Observing any changes in behavior, appetite, or energy levels can be the first step in identifying health issues. Engaging in open communication with your veterinarian about observations and concerns can pave the way for effective treatment strategies.

-

Prevention is always better than cure. Regular veterinary check-ups, maintaining a clean living environment, and restricting contact with infected animals are essential steps in preventing mange. Moreover, certain topical preventatives can help reduce the likelihood of a mite infestation.

-

While cold laser therapy is promising, it is essential to consult with a veterinarian who is knowledgeable about the technique and its applications. They can evaluate your dog's specific condition and determine if cold laser therapy is a suitable option. Additionally, treatment protocols can vary based on the ailment, so a personalized plan is crucial for maximizing benefits.

-

The Importance of Dog Vitamins for Puppies

-

Conclusion

-

Vitamin E is a potent antioxidant that plays a crucial role in protecting cellular membranes from oxidative damage. In cattle, sufficient levels of Vitamin E contribute to immune function, muscle development, and overall growth. It is particularly important during times of stress, such as calving, transportation, or feed changes, when oxidative stress can increase. Without adequate Vitamin E, cattle may show signs of muscle degeneration, weakness, and a reduced immune response, making them more susceptible to infections and illnesses.

-

Preventing loose motion in cattle begins with good management practices. Maintaining a consistent diet, observing cattle for any signs of distress, and ensuring proper sanitation in living quarters can greatly reduce the incidence of diarrhea. Vaccination against specific viruses, such as BVDV, can also offer significant protection.

-

Caring for a pregnant or nursing dog requires special attention to her nutritional needs. Ensuring that she receives adequate vitamins and minerals is vital for her health and the health of her puppies. With the right diet and supplements, pet owners can help their mommy dogs enjoy a healthy pregnancy and provide the best start for their little ones. Always keep in mind that consulting with a veterinarian is the best way to tailor a nutrition plan that fits the individual needs of your furry friend.

-

1. Ingredients Look for supplements containing high-quality, proven ingredients. Research the benefits of each ingredient and how they work together to support joint health.

-

Traditional Chinese Medicine for Dogs A Holistic Approach to Canine Health

-

Understanding 8% in 1 Vitamins for Dogs A Comprehensive Guide

-

Gout is a significant concern in poultry medicine, with potential impacts on bird health and production levels. By understanding its causes, symptoms, and management strategies, poultry farmers can mitigate the risk of gout in their flocks. A proactive approach, focusing on nutrition, hydration, and environmental management, will not only help prevent gout but also enhance the overall welfare and productivity of poultry.

-

Veterinary medicine plays a crucial role in animal health, welfare, and management. Just like humans, animals require medical attention, which often involves the use of various drugs for treatment and prevention of diseases. Understanding the common veterinary drugs and their uses is essential for veterinarians, pet owners, and anyone involved in animal care.

-

Natural Alternatives

-

Challenges and Responsible Use

-

Over-the-counter medications are drugs that can be purchased without a prescription. For dogs, these medications can alleviate minor health issues such as mild pain, allergies, digestive problems, and more. However, just because a medication is available without a prescription does not mean it is safe for all dogs. The ideal treatment depends on various factors, including the dog’s size, breed, age, and overall health condition.

-

Conclusion

-

Frequency of Dosing

-

Poor dental health can also have systemic effects on a dog's body. Bacteria from the mouth can enter the bloodstream, potentially damaging vital organs such as the heart, liver, and kidneys. This emphasizes the need for vigilant dental care.

-

1. Aspirin In small doses, this NSAID can provide relief from pain and inflammation. However, it must be used sparingly and never for an extended period. Always consult a vet for the appropriate dosage and to ensure there are no underlying health issues.

-

Dog infection tablets are medications specifically formulated to treat bacterial, viral, or fungal infections in dogs. They contain active ingredients that work to target and eliminate the pathogens causing the infection. These tablets can be prescribed by veterinarians based on the specific needs of the dog and the nature of the infection.

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire