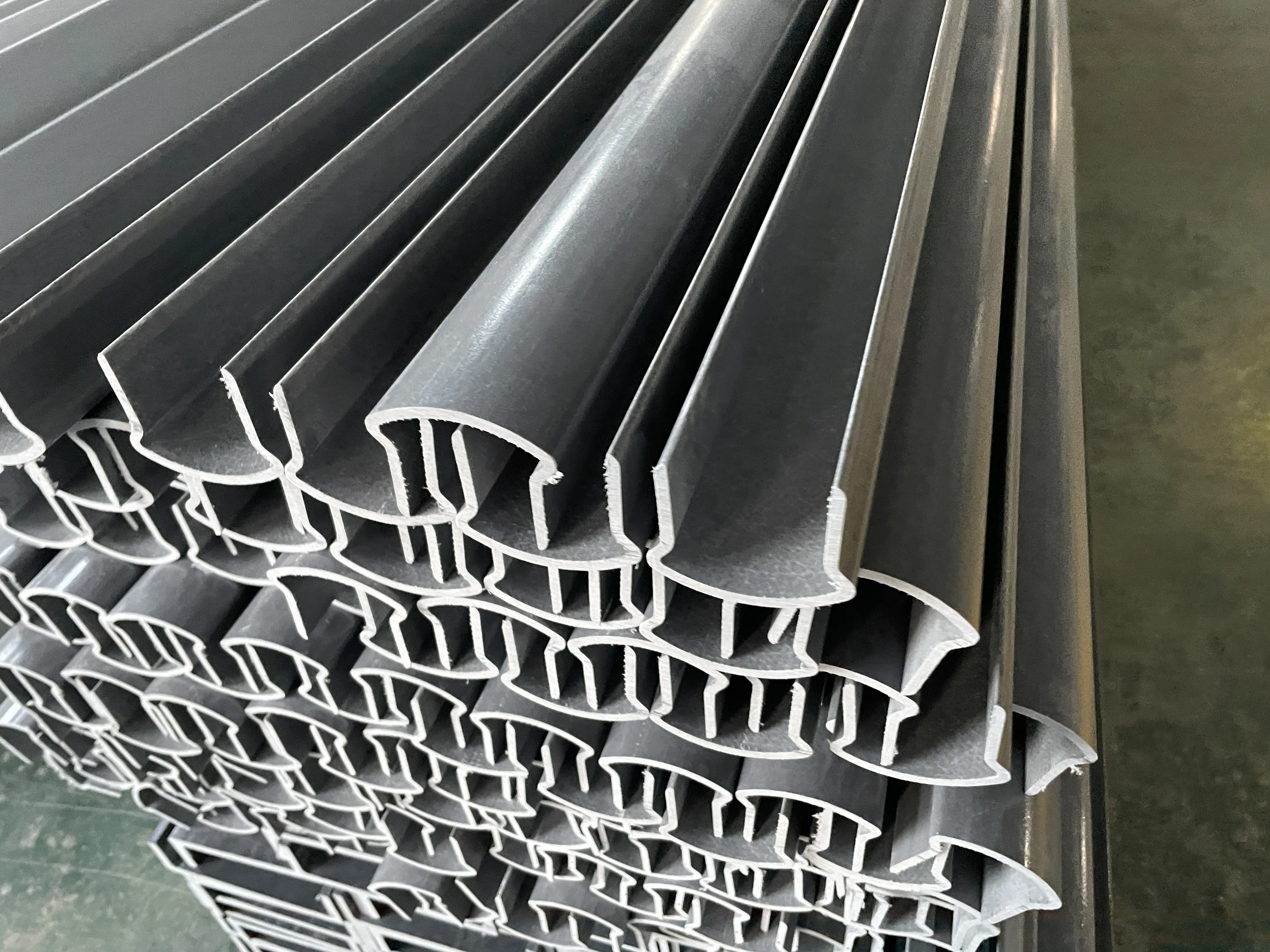

grp handrail systems

Materials used

An oil seal has two tasks: Keeping the lubricant in and keeping dirt and contaminants out of rotating components. This separation must be accomplished between surfaces in relative motion, usually a shaft or bearing inner ring and a housing. With correct installation, oil seals can also prevent seal leakage and maintain the lubricity of a bearing to ensure that the rotary shaft and its bearings remain fully functional.

Please see the following for the types of sealing devices for bearings.

How to Select the Right Bearing (Part 7): Components surrounding the bearing

Variety of Oil Seals

How Oil Seals

④

O-Rings

Installation of the oil seal

Nitrile Butadiene Rubber (NBR, nitrile)

×