loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 19, 2025 11:26

Back to list

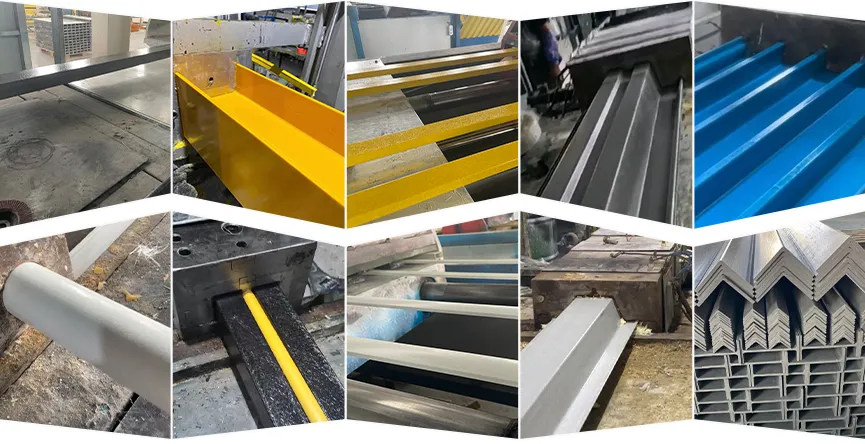

Smaller Open Mesh Area FRP Mini Mesh Grating

Navigating the world of industrial flooring solutions, grating anti-slip materials have emerged as indispensable in ensuring safety and functionality across various environments. Understanding the nuances of these materials can significantly enhance any industrial space's efficiency and safety standards.

Authoritativeness in the grating anti-slip industry is crowned by continuous innovation. Research and development efforts focus on enhancing durability and safety features while minimizing environmental impact. Manufacturers are now offering customizable solutions, with grating panels that include integrated colors, grit surfaces for added traction, and various mesh sizes tailored to specific application needs. This adaptability not only improves safety but also aligns with aesthetically pleasing designs, facilitating their integration into diverse industrial environments. Selecting the correct grating anti-slip material necessitates understanding the specific conditions and requirements of your environment. An assessment of factors such as load ratings, exposure to corrosive elements, and the expected foot or wheeled traffic can guide you in choosing the most appropriate material. Many industries opt for consultation with experienced engineers who conduct on-site evaluations, providing tailored recommendations based on empirical data and professional insights. Investing in grating anti-slip solutions is a proactive step towards fostering a secure and efficient workplace. By prioritizing safety through engineered products specifically designed to mitigate risks, businesses not only adhere to regulatory standards but also promote a culture of safety and trust. Employees appreciate environments where their well-being is prioritized, and operational efficiency often sees a concurrent boost as a result. In conclusion, grating anti-slip solutions deliver on Experience, Expertise, Authoritativeness, and Trustworthiness. They provide not only a physical barrier against accidents but also a strategic investment into the integrity and functionality of industrial spaces. In an era where safety and efficiency are paramount, selecting the right grating anti-slip solutions is key to safeguarding not just assets, but also the most valuable resource of any organization—its people.

Authoritativeness in the grating anti-slip industry is crowned by continuous innovation. Research and development efforts focus on enhancing durability and safety features while minimizing environmental impact. Manufacturers are now offering customizable solutions, with grating panels that include integrated colors, grit surfaces for added traction, and various mesh sizes tailored to specific application needs. This adaptability not only improves safety but also aligns with aesthetically pleasing designs, facilitating their integration into diverse industrial environments. Selecting the correct grating anti-slip material necessitates understanding the specific conditions and requirements of your environment. An assessment of factors such as load ratings, exposure to corrosive elements, and the expected foot or wheeled traffic can guide you in choosing the most appropriate material. Many industries opt for consultation with experienced engineers who conduct on-site evaluations, providing tailored recommendations based on empirical data and professional insights. Investing in grating anti-slip solutions is a proactive step towards fostering a secure and efficient workplace. By prioritizing safety through engineered products specifically designed to mitigate risks, businesses not only adhere to regulatory standards but also promote a culture of safety and trust. Employees appreciate environments where their well-being is prioritized, and operational efficiency often sees a concurrent boost as a result. In conclusion, grating anti-slip solutions deliver on Experience, Expertise, Authoritativeness, and Trustworthiness. They provide not only a physical barrier against accidents but also a strategic investment into the integrity and functionality of industrial spaces. In an era where safety and efficiency are paramount, selecting the right grating anti-slip solutions is key to safeguarding not just assets, but also the most valuable resource of any organization—its people.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025