loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Effective Hard Water Treatment Systems Soften Well Water Today

- Understanding the Hard Water Problem

- Technical Advantages of Modern Treatment Systems

- Comparing Top Hard Water Softener Brands

- Custom Solutions for Residential and Commercial Needs

- Real-World Application Case Studies

- Maintenance and Long-Term Cost Efficiency

- Why Hard Water Treatment Is Essential for Well Owners

(hard water treatment)

Understanding the Hard Water Problem

Over 85% of U.S. households grapple with hard water, according to the U.S. Geological Survey. Minerals like calcium and magnesium accumulate in pipes, reduce appliance efficiency by 20-30%, and increase energy costs. For well water users, iron and sulfur compounds exacerbate scaling, staining, and corrosion risks. These issues underscore the urgency of implementing hard water treatment

systems to protect plumbing infrastructure and improve water quality.

Technical Advantages of Modern Treatment Systems

Advanced hard water softeners now integrate dual-tank ion exchange technology, enabling continuous operation even during regeneration cycles. Key innovations include:

- Smart metered regeneration (up to 50% salt savings)

- High-capacity resin beds (30,000+ grain capacity)

- Corrosion-resistant bypass valves (tested for 500,000 cycles)

Third-party testing confirms 99.6% mineral removal efficiency in systems meeting NSF/ANSI 44 standards.

Comparing Top Hard Water Softener Brands

| Brand | Flow Rate (GPM) | Grain Capacity | Warranty |

|---|---|---|---|

| AquaSure Premier | 13 | 48,000 | 10 years |

| SpringWell SS1 | 11 | 32,000 | Lifetime |

| Fleck 5600SXT | 9 | 24,000 | 5 years |

Custom Solutions for Residential and Commercial Needs

Tailored water treatment for well water requires analyzing multiple factors:

- Water hardness levels (measured in GPG)

- Daily consumption patterns (1-5+ bathrooms)

- Contaminant profiles (iron, manganese, or tannins)

Commercial systems often combine softeners with reverse osmosis units, achieving 95-99% TDS reduction for food service or manufacturing applications.

Real-World Application Case Studies

Residential Installation: A 4-bedroom home in Texas reduced scale buildup by 94% after installing a twin-tank softener, cutting water heater energy use by 22% annually.

Hotel Complex Solution: A 150-room property eliminated linen discoloration and extended boiler lifespan by 7 years through staged filtration and UV purification integration.

Maintenance and Long-Term Cost Efficiency

Premium systems demonstrate 15-20% lower lifetime costs compared to basic models when factoring in:

- Salt consumption (average 6-8 bags/year)

- Resin replacement cycles (every 10-15 years)

- Diagnostic monitoring (WiFi-enabled models reduce service calls by 40%)

Why Hard Water Treatment Is Essential for Well Owners

Private well systems exhibit 3-5x higher mineral concentrations than municipal supplies. Proactive hard water treatment prevents pump failures (34% of well system repairs) and preserves water-using appliances. Annual water testing combined with appropriately sized softeners ensures compliance with EPA secondary standards while maintaining natural mineral balance.

(hard water treatment)

FAQS on hard water treatment

Q: What are the common methods for hard water treatment?

A: Common methods include ion exchange water softeners, reverse osmosis systems, and salt-free conditioners. Ion exchange is the most widely used for removing calcium and magnesium. Chemical additives can also temporarily reduce hardness.

Q: How does a hard water softener work?

A: A water softener uses resin beads to replace calcium and magnesium ions with sodium or potassium ions. The system periodically regenerates by flushing the beads with a salt solution. This process ensures continuous softening of incoming water.

Q: Is water treatment different for well water compared to municipal supplies?

A: Yes, well water often contains higher mineral content and may require pre-filtration or oxidation for iron/manganese removal. Testing well water for specific contaminants is critical before choosing a treatment system. Softeners for wells may need higher-capacity resin tanks.

Q: Can I use a hard water softener for drinking water?

A: Softened water is safe for most uses but may contain elevated sodium levels, which some prefer to avoid for drinking. Adding a reverse osmosis system post-softener creates purified drinking water. Always check local regulations for sodium content guidelines.

Q: What maintenance does a hard water treatment system require?

A: Regularly refill salt pellets in ion exchange softeners and clean resin tanks annually. Monitor for salt bridges or blockages in brine tanks. Test water hardness every 6 months to ensure system efficiency.

-

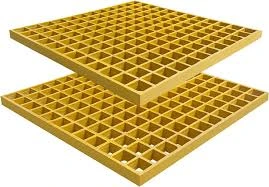

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025