loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring CHS Hollow Sections for Structural Engineering Applications and Innovations

Understanding CHS Hollow Sections A Comprehensive Guide

Hollow sections are integral elements in modern structural design, and among these, Circular Hollow Sections (CHS) have gained immense popularity. This article delves into the applications, benefits, and structural mechanics of CHS hollow sections, offering insights into their significance in various engineering fields.

What are CHS Hollow Sections?

Circular Hollow Sections (CHS) are structural steel elements characterized by their circular cross-sections. They are manufactured from rolled or welded steel and can be used in various applications, ranging from construction to manufacturing. The distinct design of CHS provides several advantages, including aesthetic appeal, efficient material usage, and superior structural performance.

Material Efficiency

One of the primary reasons for the increased use of CHS is their ability to handle high loads while using minimal material. The hollow design allows for a significant reduction in weight compared to other solid sections while maintaining strength. This efficiency means that fewer raw materials are consumed in production, which can lead to cost savings and a lower environmental impact. The optimized strength-to-weight ratio makes CHS an ideal choice for engineers looking to design lightweight structures without compromising stability.

Structural Performance

CHS hollow sections are remarkably versatile when it comes to structural performance. Their circular geometry provides uniform distribution of stress and excellent resistance to buckling, making them suitable for various load conditions. Whether subjected to axial or moment loading, CHS columns and beams demonstrate superior load-bearing capacities, often outperforming traditional I-beams in specific applications.

Furthermore, their seamless design allows for superior resistance to torsion, which is particularly beneficial in applications where twisting forces are present. This makes CHS a favored choice in challenging structural situations, such as cantilevers and towers.

Aesthetic Appeal

chs hollow section

In addition to their mechanical properties, CHS hollow sections offer impressive aesthetic benefits. Their smooth, circular profile provides a contemporary look, making them popular in architectural applications. Structures utilizing CHS can achieve a modern appearance while benefitting from the principles of sustainable and efficient design.

Designers and architects increasingly rely on the visual appeal of CHS in their projects. They can be used both as load-bearing elements and as design features, seamlessly integrating into the architectural vision of a building. This dual functionality enhances their desirability in both commercial and residential projects.

Applications of CHS

CHS hollow sections are employed in a wide range of applications across various industries. In the construction sector, they serve as columns, beams, and trusses in buildings and bridges. Their high strength, coupled with their aesthetic qualities, makes them ideal for modern architectural designs.

In the manufacturing industry, CHS is frequently used in the production of frames for machinery, scaffoldings, and support structures. The automotive industry also utilizes CHS for the construction of car chassis due to their weight efficiencies and load-bearing capabilities.

Moreover, in the context of infrastructure, CHS sections provide exceptional support in telecommunications towers and wind turbine structures, where strength and durability are paramount under varying environmental conditions.

Connection Techniques

The effectiveness of CHS hollow sections is further enhanced by the variety of connection techniques available. From welding to bolted connections, the choice of method influences the overall performance of the structure. Careful consideration must be given to the connection design to ensure that the full strength of the CHS is utilized. Specialized connection methods, such as grouted connections and splice connectors, have also been developed to address unique challenges.

Conclusion

In conclusion, Circular Hollow Sections represent a critical component of modern construction and manufacturing. Their combination of strength, aesthetic versatility, and material efficiency makes them an attractive option for engineers and architects alike. As innovation in design continues to evolve, the application and development of CHS hollow sections will undoubtedly expand, reinforcing their role as a cornerstone in the realm of structural engineering. Their ability to meet diverse design requirements while maintaining robust performance solidifies their status as a fundamental choice for future construction projects.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

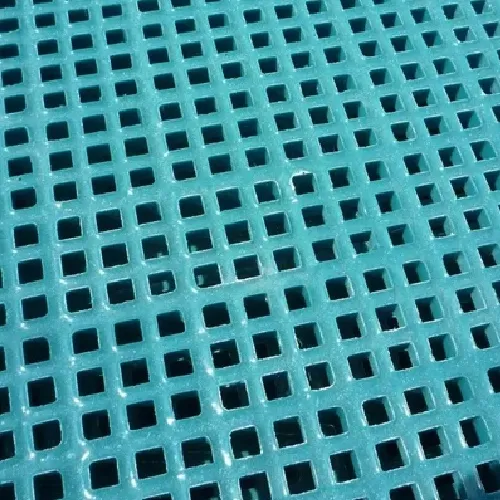

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025