loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Grating Suppliers: Corrosion-Resistant, Custom, Fast

What to Know Before Choosing FRP Grating Suppliers (From Someone Who’s Toured the Factories)

If you’re shopping around for frp grating suppliers, here’s a field note: the best vendors aren’t just selling panels—they’re shipping reliability, test data, and predictable lead times. I’ve walked shop floors that smell like styrene and watched moulds being de-moulded at 5 a.m. It’s surprisingly methodical, and yes, small differences in resin and glass content change everything.

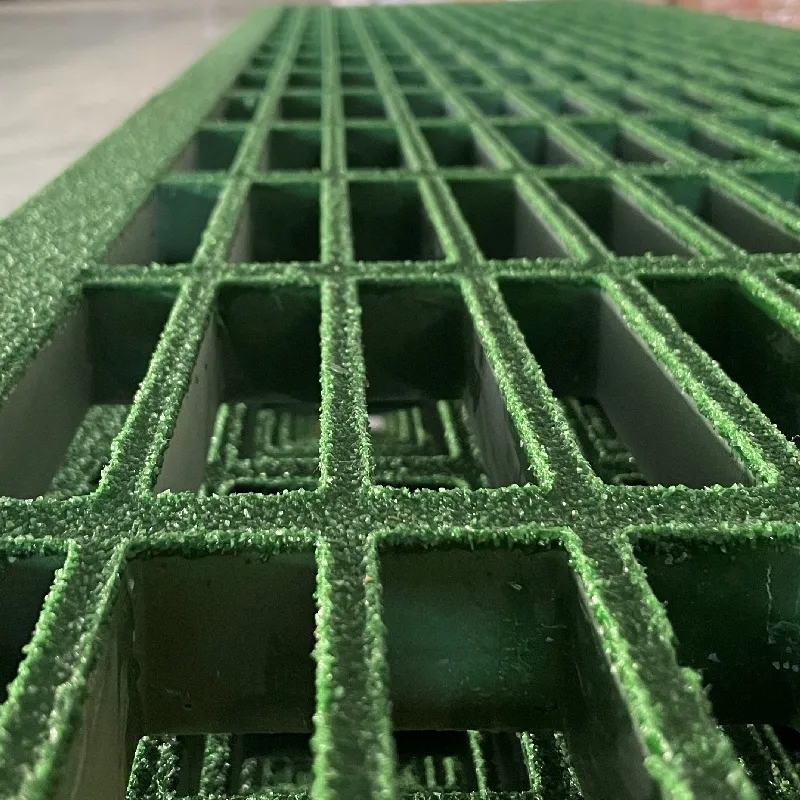

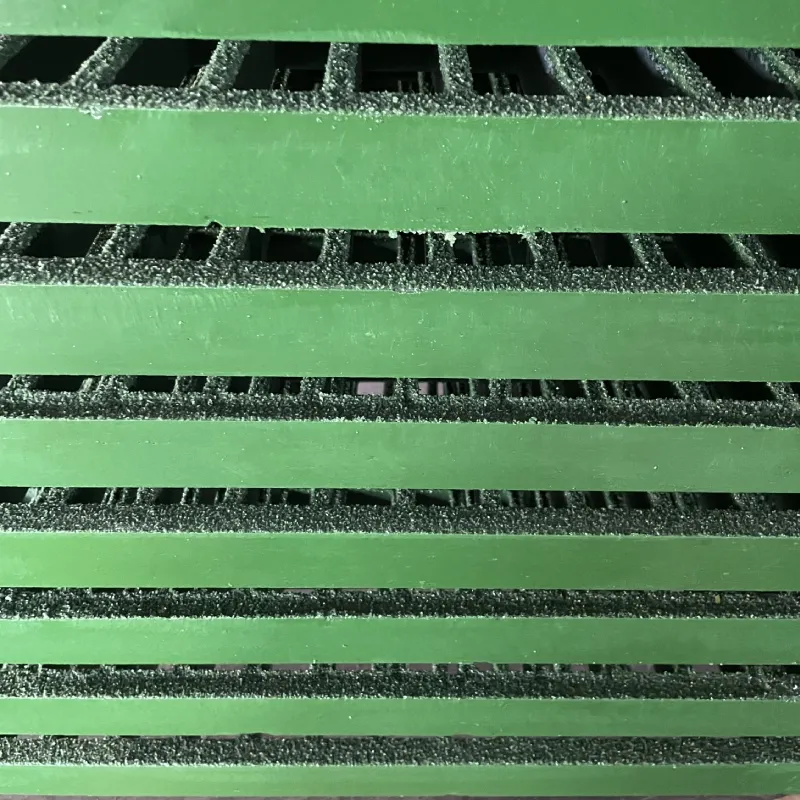

Product snapshot: Moulded Fiberglass Rectangular Mesh Grating

This rectangular mesh blends the “open area” of traditional square grating with the finer foot-friendly profile of mini mesh. In practice, that means brighter decks, better drainage, and fewer lost bolts rolling around. You’ll see it on marine walkways, aquaculture platforms, urban access ways, mineral processing lines, and farm flooring. The manufacturer I visited is based at No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China—hard to pronounce, easy to remember for consistent quality.

Specs that actually matter

| Parameter | Typical value (≈) | Notes |

|---|---|---|

| Thickness / Mesh | 25–38 mm / rectangular mesh | Panel size and span affect load |

| Resin systems | Orthophthalic, Isophthalic, Vinyl ester | Phenolic on request for fire-critical areas |

| Flexural strength (ASTM D790) | 200–350 MPa | Real-world use may vary with temperature |

| Modulus (ASTM D790) | 7–10 GPa | Span/deflection check is essential |

| Slip resistance (ASTM D2047) | Static COF ≥ 0.6 (gritted top) | Wet areas benefit from extra grit |

| Fire test (ASTM E84) | Flame spread ≤ 25 with VE/phenolic | Specify when needed for code |

Service life? In marine and chemical splash zones, I usually pencil in 20–30 years, provided UV topcoat is intact and supports are well detailed. Many customers say the maintenance delta vs. galvanized steel pays back faster than expected—no rust creep, fewer shutdowns.

Process flow (why consistency wins)

- Materials: E-glass roving + mat, resin (ISO/VE), pigments, UV and fire-retardant additives.

- Moulding: Wet lay-up into heated moulds; curing and controlled demould; edge finishing.

- Testing: ASTM D638/D790 mechanicals, ASTM E84/D635 fire/flammability, ASTM G154 UV, load/deflection on span charts.

- QC: Barcol hardness checks, fiber volume fraction sampling, gel-coat thickness, dimensional tolerance.

- Certs: ISO 9001; some projects request ABS/DNV marine approvals depending on region.

Where it’s being used (and holding up)

- Marine piers and ferry terminals: brighter decks, less corrosion.

- Aquaculture and farming: drainage plus easy wash-down.

- Urban/public access ways: non-spark, slip-resistant surfaces.

- Mineral processing and chemical plants: corrosion resistance around acids/alkalis.

Quick case notes: a coastal wastewater upgrade switched to rectangular mesh for open area and reported 15% faster inspections (more light under platforms). Another plant in hot, briny air saw zero rust-related rework after two monsoon seasons—anecdotal, but telling.

Comparing frp grating suppliers (what I actually ask)

| Supplier | Certifications | Resin options | Lead time (≈) | Notes |

|---|---|---|---|---|

| ZJ Composites (Hengshui, CN) | ISO 9001; ASTM reports | Ortho/ISO/VE; phenolic on request | 2–4 weeks | Strong rectangular mesh program |

| Regional Supplier A | ISO 9001 | Ortho/ISO | 3–6 weeks | Good for small MOQs |

| EU Supplier B | ISO 9001; CE docs | ISO/VE | 2–5 weeks | Tight tolerance, higher price |

Customization checklist

- Panel size, thickness, span; cut-outs for penetrations.

- Grit level and color (safety yellow/grey/green popular).

- UV topcoat, fire-retardant package, conductive options.

- Clips and supports: stainless or FRP fixings to match corrosion class.

Bottom line: shortlist frp grating suppliers who publish test data, offer span/load charts, and can talk intelligently about resin choice for your environment. Sounds obvious, but it filters the field fast.

References

- ASTM D790 – Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics.

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials.

- ASTM D2047 – Standard Test Method for Static Coefficient of Friction of Polish-Coated Flooring Surfaces.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025