loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fibre reinforced plastic tanks

Fibre Reinforced Plastic Tanks A Modern Solution for Storage Needs

Fibre Reinforced Plastic (FRP) tanks have emerged as one of the most reliable and efficient solutions for storing various liquids, including water, chemicals, and even wastewater. As industries expand and environmental regulations tighten, the demand for durable, lightweight, and corrosion-resistant storage options has surged. This article will explore the benefits, applications, and innovations associated with FRP tanks, highlighting why they are becoming the preferred choice in numerous sectors.

What is Fibre Reinforced Plastic?

Fibre Reinforced Plastic is a composite material made by combining a polymer matrix with reinforcing fibres, typically glass, carbon, or aramid. This combination results in a material that is not only lightweight but also possesses enhanced mechanical strength and resistance to environmental degradation. The versatility of FRP allows it to be molded into various shapes and sizes, accommodating a wide range of applications.

Benefits of FRP Tanks

One of the foremost advantages of FRP tanks is their exceptional corrosion resistance. Traditional materials such as steel or concrete can be susceptible to damage from chemicals or prolonged exposure to moisture. In contrast, FRP tanks can withstand harsh chemical environments, making them ideal for industries that handle aggressive substances, such as petrochemicals, pharmaceuticals, and wastewater treatment.

In addition to corrosion resistance, FRP tanks are significantly lighter than their steel or concrete counterparts. This lightweight nature facilitates easier transportation and installation, reducing labor costs and time spent on setup. Furthermore, the flexibility of FRP allows for custom designs tailored to specific requirements, accommodating confined spaces or unusual site conditions.

Another notable benefit is the reduced maintenance associated with FRP tanks. Unlike traditional storage tanks, which may require periodic painting or treatment to combat corrosion, FRP tanks typically need minimal upkeep. This not only lowers operational costs but also enhances overall efficiency by minimizing downtime.

fibre reinforced plastic tanks

Applications of FRP Tanks

Given their unique properties, FRP tanks find applications across various industries. In the water treatment sector, they are often used for storing potable water, chemicals, and wastewater, thanks to their resistance to corrosion and environmental factors. In the agricultural sector, FRP tanks serve as effective solutions for storing fertilizers and pesticides, preventing contamination and ensuring safe handling.

Moreover, the oil and gas industry has adopted FRP tanks for storing crude oil, refined products, and chemicals. The lightweight nature and resistance to abrasion make these tanks suitable for storage at drilling sites and refineries. Additionally, the transportation and shipping industries utilize FRP tanks for their ability to maintain temperature stability and prevent leakage.

Innovations in FRP Tank Technology

The advancement of technology has played a crucial role in enhancing FRP tank manufacturing processes. Innovations such as automated filament winding, pultrusion, and resin transfer molding have improved the quality and consistency of FRP tanks. These methods lead to a more efficient production cycle, allowing manufacturers to meet growing market demands while maintaining high standards.

Furthermore, with the increasing focus on sustainability, many manufacturers are now exploring the use of recycled materials in the production of FRP tanks. This initiative not only reduces waste but also aligns with global efforts toward environmental conservation.

Conclusion

In conclusion, Fibre Reinforced Plastic tanks represent a significant advancement in storage technology. Their corrosion resistance, lightweight design, and low maintenance requirements make them an ideal choice for various applications across multiple industries. As technology continues to evolve, FRP tanks are poised to become an even more crucial component in the modern landscape of industrial storage solutions, paving the way for safer, more efficient, and environmentally friendly practices.

-

Revolutionary Modular Handrail Systems Redefine Safety StandardsNewsMay.15,2025

-

Innovative Water Treatment Technologies for Purer WaterNewsMay.15,2025

-

Innovative Square Water Tank SystemsNewsMay.15,2025

-

Innovative Galvanized Steel Water TanksNewsMay.15,2025

-

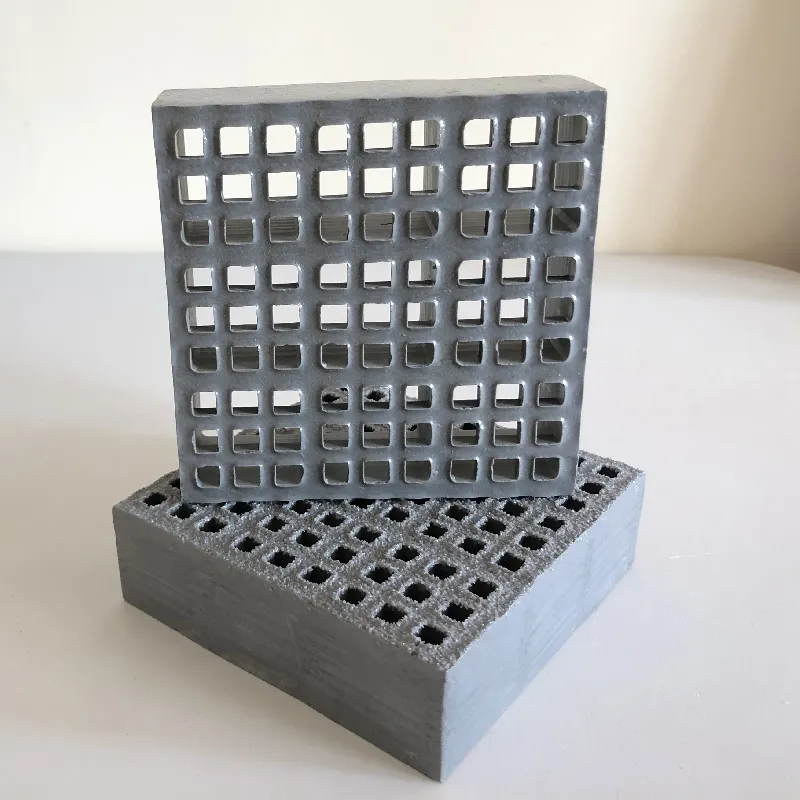

Innovative FRP Grating Products Revolutionize Industrial FlooringNewsMay.15,2025

-

Fiberglass Storage Tanks for Reliable Water SolutionsNewsMay.15,2025

-

The Benefits and Uses of Covered Grating SolutionsNewsMay.12,2025