loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Grating Suppliers for Durable Solutions | FRP Micro Mesh Grating

www.zjcomposites.com

Phone: +86 15031801825 | Mobile: +86 15097380338

Email: admin@zjcomposites.com

Address: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

Fiber Reinforced Plastic (FRP) grating, sometimes referred to as Glass Reinforced Plastic (GRP) grating, has revolutionized the industrial flooring and structural applications market. With key advantages such as corrosion resistance, non-conductivity, and a high strength-to-weight ratio, FRP grating suppliers now serve virtually every continent. As cited in the CompositesWorld Industry Insights, global FRP grating demand is projected to grow at over 6% CAGR through 2030, driven by infrastructure upgrades, stricter workplace safety standards, and environmental sustainability (source).

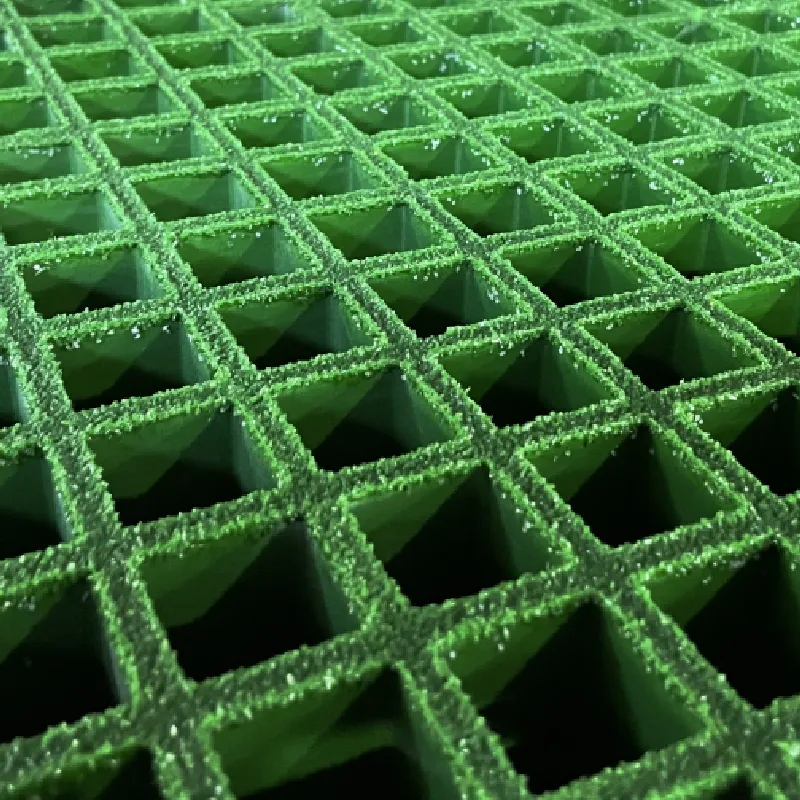

Technological Advancements: FRP Micro Mesh GratingThe evolution of FRP micro mesh grating represents a significant leap forward in addressing requirements for finer particle retention, increased anti-slip capability, and fire retardancy. Micro mesh variants offer mesh apertures typically below 13mm, ideal for environments requiring prevention of small object drop-through or added slip resistance, such as food processing, power generation, and data centers (Composites UK Technical Briefing).

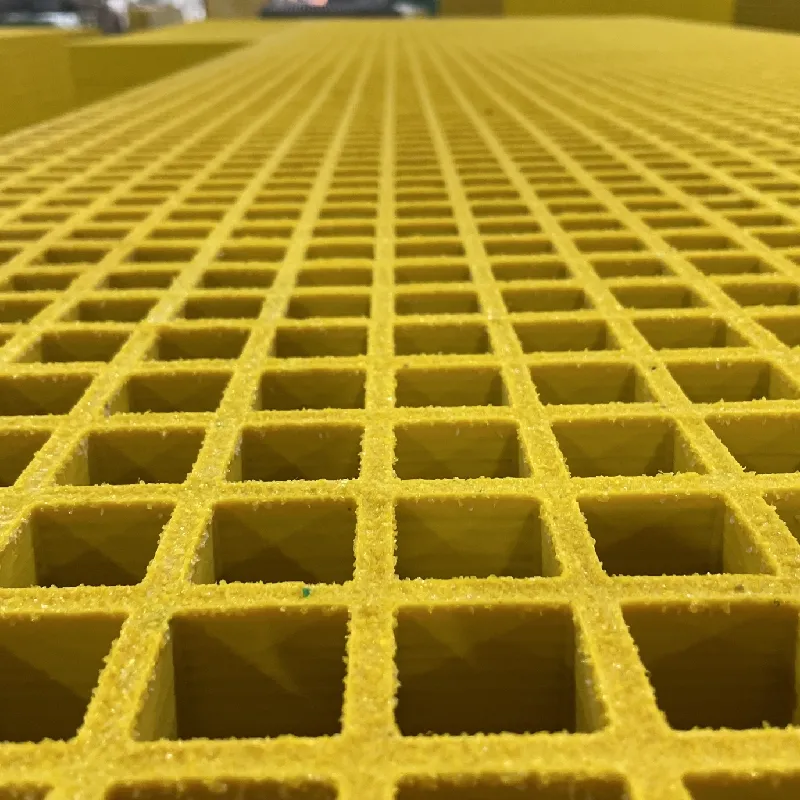

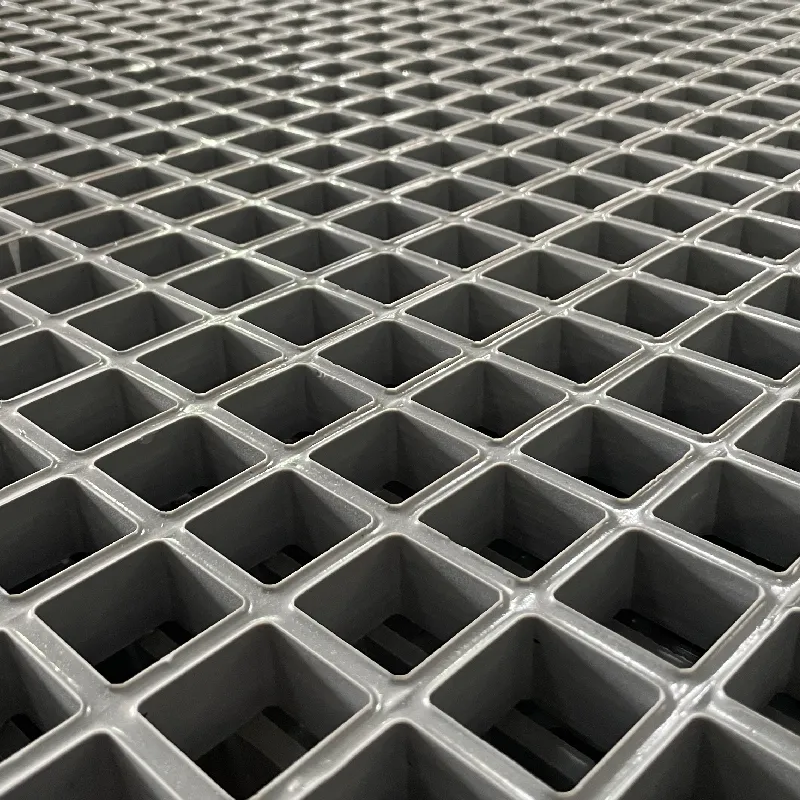

Product Spotlight: Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating- Product Name: Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating

- Product Link: Visit Product Page

- Product Introduction: FRP/GRP/Fiberglass (Fiberglass Reinforced Plastic) grating is a clear choice over steel or aluminum grating. Our featured grating is UV stable and will not crack, degrade, or deform when exposed to the elements. Being lighter in weight, it is also easier and quicker to install—requiring no special tools or hot works. Ideal for harsh, corrosive, or outdoor environments.

| Supplier | Grating Type | Standard Mesh Size | Load Capacity (KN/m²) | Corrosion Resistance | Fire Retardancy | Certification |

|---|---|---|---|---|---|---|

| Zhaojia Composites Co., Ltd | Standard/Micro Mesh FRP | 38x38mm / 13x13mm | ≥50 | Excellent | ASTM E84 Class 1 | ISO9001:2015 |

| Supplier B (Global) | Standard FRP | 30x30mm | 45 | Good | BS 476 Part 7 | CE |

| Supplier C (Asia) | Micro Mesh GRP | 13x13mm | 42 | Excellent | EN 13501-1 | ISO/CE |

| Supplier D (US) | Industrial FRP | 38x38mm | 56 | Very Good | UL 94V-0 | UL Listed |

Key Technical Specifications of Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating

| Characteristic | Specification |

|---|---|

| Material | Fiberglass Reinforced Plastic |

| Standard Mesh Size | 38mm x 38mm (also 13mm x 13mm) |

| Thickness | 25mm / 30mm / 38mm |

| Bearing Bar Height | 25~40 mm |

| Open Area | ~69% |

| Slip Resistance | Excellent (ASTM D2047 tested) |

| Fire Retardancy | ASTM E84 Class 1 (Flame Spread < 25) |

| Corrosion Resistance | Outstanding (to Chemicals/Salts/Acids) |

| Color Options | Gray, Yellow, Green, Custom |

| Certificates | ISO9001, SGS, CE |

Applications & Industry Use Cases of FRP Grating Suppliers

- Industrial walkways and platforms in corrosive environments (chemical, petrochemical, marine)

- Food/beverage processing (thanks to FRP micro mesh grating fine aperture)

- Cooling tower in-fills and rooftop grating

- Data center cable management floor

- Wastewater treatment plant walkways

- Parks and landscape pedestrian bridges

- Electrical substations & non-conductive safety zones

Major advantages such as lightweight installation, UV stability, fire/bacteria resistance, safety under wet/oily conditions, and zero requirement for welding/hot work drive the demand for FRP grating suppliers across sectors. The lightweight feature, for example, often reduces labor costs by up to 30% compared to steel installations (reference).

Professional Q&A: Technical Terms Explained- 1. What materials are used in FRP grating?

- FRP grating is constructed using E-glass or C-glass fibers and thermoset resins such as isophthalic, orthophthalic, vinyl ester, or phenolic, enhancing corrosion resistance and structural integrity (source).

- 2. What is the typical mesh size of FRP micro mesh grating?

- FRP micro mesh grating generally features 13x13mm or 19x19mm apertures, designed to prevent small object loss and maximize slip-resistance for personnel safety.

- 3. Which international certifications are important for FRP grating suppliers?

- ISO9001, CE, ASTM E84 (fire), UL94, SGS, and EN13501–1 are key certifications ensuring product quality, fire safety, and regulatory compliance.

- 4. What is the recommended installation standard for FRP grating?

- According to the American Institute of Steel Construction (AISC) and international best practices, FRP grating must be supported by appropriate structure; installation with stainless steel clips every 450mm ensures stability without the need for welding.

- 5. How do fire retardant properties of FRP gratings compare to metal?

- High-grade FRP uses fire-retardant resins and meets ASTM E84 Class 1, with flame spread index below 25, matching or exceeding most standard metals (see reference).

- 6. Are FRP grating suppliers able to provide custom colors and sizes?

- Yes, reputable FRP grating suppliers including Zhaojia Composites offer custom mesh sizes, thicknesses, colors and even extra anti-slip coatings, tailored to industrial needs.

- 7. What are typical applications where FRP micro mesh grating is superior?

- It is optimal for cleanrooms, food & beverage plants, urban landscaping, and public walkways, especially where small-object safety and slip-resistance are critical.

- Proven Industry Authority: Decades of manufacturing expertise, ISO 9001/SGS-certified output.

- Innovative Product Line: Standard mesh, micro mesh, molded and pultruded options, wide color spectrum.

- Tailored Engineering: In-house R&D, custom chemical formulas, anti-static and extra fire-retardant models.

- Factory Direct Pricing: Elimination of unnecessary markups, real factory outlet value.

- Global Shipping & Service: International logistics and dedicated technical support teams.

Tel: +86 15031801825 | Email: admin@zjcomposites.com | Address: Hengshui, Hebei, China

Conclusion: The Future of FRP Grating Suppliers

As workplace SHEQ (Safety, Health, Environment, Quality) becomes paramount, collaboration with FRP grating suppliers who maintain authoritative technical capacity, rigorous global certifications, and innovative engineering is essential. The ongoing move towards micro mesh and enhanced anti-slip technologies—alongside digital supply chain integration—solidifies the role of firms like Zhaojia Composites Co., Ltd as industry vanguards.

References:[1] CompositesWorld. “FRP Grating Market Global Forecast.” www.compositesworld.com

[2] Composites UK. "Technical Briefing: Molded & Micro Mesh Gratings." www.compositesuk.co.uk

[3] MDPI Journals - Polymers. “Fire Properties of FRP Composites.” www.mdpi.com

[4] SAGE Journals. "Glass Fibers and FRP Advanced Engineering Applications." journals.sagepub.com

[5] CompositesWorld. “Composites in Infrastructure.” www.compositesworld.com

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025