loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

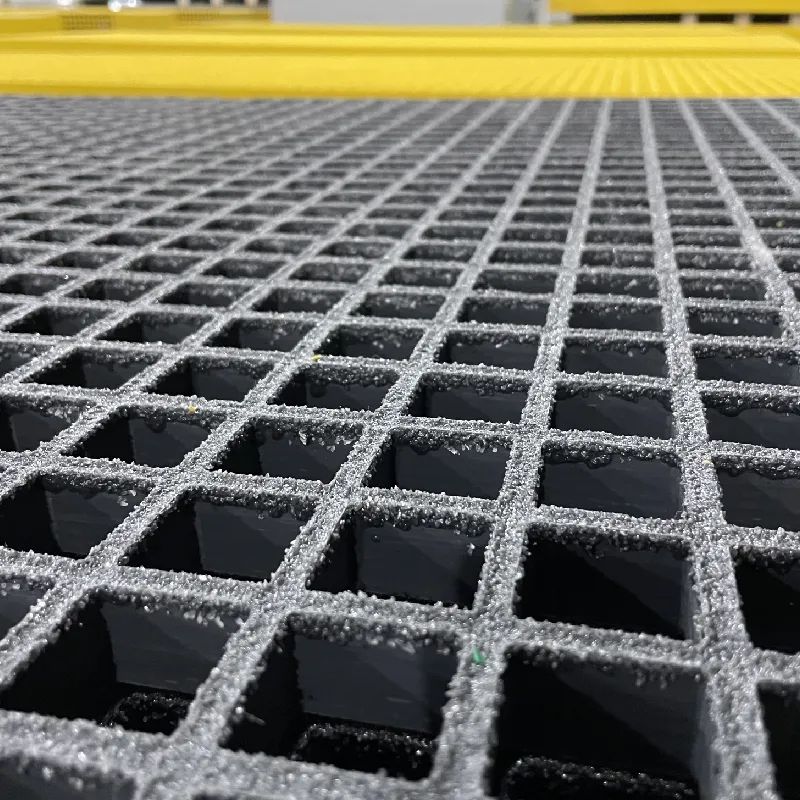

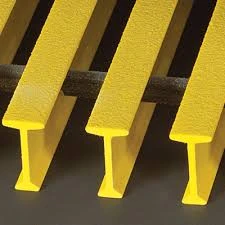

frp mesh grating

In the rapidly evolving world of industrial manufacturing and construction, the choice of materials can significantly impact performance, safety, and maintenance costs. One such material that has garnered attention for its remarkable properties is FRP (Fiber Reinforced Plastic) mesh grating. Offering a unique blend of durability, versatility, and safety, FRP mesh grating is becoming an increasingly popular choice across various sectors.

Experience with FRP mesh grating often reveals its unrivaled resilience in harsh environments. Unlike traditional materials such as steel or aluminum, FRP does not corrode, making it ideal for facilities exposed to moisture and chemicals. A plant maintenance manager from a leading chemical processing company remarked how transitioning to FRP mesh gratings eliminated constant repairs caused by rusting metal gratings, resulting in significant cost savings and increased operational efficiency.

The expertise inherent in FRP production processes ensures each grating panel meets the rigorous demands of its intended application. Engineers emphasize the lightweight nature of FRP mesh grating, which simplifies installation and reduces the structural load. This feature not only enhances safety during installation but also cuts down on labor costs. Furthermore, the intrinsic flexibility of FRP materials enables manufacturers to customize grating patterns and sizes, accommodating diverse design specifications without compromising structural integrity.

Authoritativeness in the field of construction materials is underpinned by rigorous testing and compliance with industry standards. FRP mesh grating products are often certified to meet or exceed specifications set forth by organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). This compliance ensures that FRP gratings are not just theoretically robust but proven to withstand real-world challenges. Industry leaders continue to advocate for the integration of FRP materials into safety-critical applications such as walkways and platforms in offshore drilling units, underscoring their trust in these advanced materials.

The trustworthiness of FRP mesh grating as a reliable solution is further reinforced by a track record of successful implementation across multiple industries. In wastewater treatment plants, for instance, the non-conductive nature of FRP gratings addresses safety concerns where electrical hazards are prevalent. Facilities using FRP mesh grating report fewer workplace incidents related to slips and falls due to the product's excellent slip-resistance, enhancing overall workplace safety.

In conclusion, FRP mesh grating stands out as a formidable contender in the selection of materials for modern construction and industrial facilities. Its combination of durability, flexibility, and safety features makes it a smart investment for businesses seeking to elevate their operational standards while reducing long-term costs. As industries evolve and face new challenges, the demand for innovative materials like FRP is likely to rise, offering further advancements and applications that tap into its full potential. Whether in the corrosive environment of a chemical plant or the hazardous conditions of an oil rig, FRP mesh grating demonstrates a commitment to safety and efficiency that modern industries cannot afford to overlook.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025