loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating: Anti-Slip, Corrosion-Resistant FRP Panels

Covered Grating is a key solution in the manufacturing industry, specifically within Manufacturing of building materials and other building components and Manufacturing of non-metallic structural components for construction. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Covered Grating Overview

- Benefits & Use Cases of Covered Grating in Manufacturing of non-metallic structural components for construction

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Covered Grating from Zhaojia Composites Co., Ltd

Covered Grating Overview

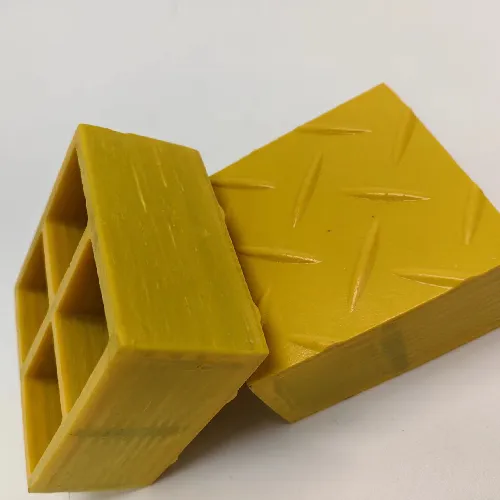

Covered grating—often called a grating cover or solid-top FRP grating—is a composite flooring and decking solution that combines a molded or pultruded fiberglass grating base with a bonded or integrally molded solid plate. The result is a closed, slip-resistant surface that prevents debris drop-through, blocks splash, and improves walking comfort while maintaining excellent load-bearing performance. In the context of Manufacturing of building materials and other building components, covered grating enables cleanable, non-conductive, and corrosion-resistant platforms, mezzanines, and trench covers. For Manufacturing of non-metallic structural components for construction, it offers long-term durability without the recurrent maintenance of painted steel.

- Typical specifications include panel thicknesses from 25–38 mm with 3–5 mm solid plates, silica-grit anti-slip surfaces, and resin options (isophthalic or vinyl ester) for enhanced chemical resistance and UV stability.

- Common formats include cut-to-size trench covers, machine-access platforms, and walkways, engineered to meet project load and deflection criteria while minimizing weight.

- Zhaojia Composites Co., Ltd, an experienced FRP grating manufacturer, provides quality-controlled production, precise fabrication, and reliable delivery for industrial users seeking robust covered grating systems.

Benefits & Use Cases of Covered Grating in Manufacturing of non-metallic structural components for construction

In construction-centric manufacturing environments—chemical processing equipment shops, precast component plants, and modular building factories—covered grating serves as a versatile, high-performance surface. It functions as a sealed grating cover for trenches and cable pits, prevents tools and aggregates from falling through in batching areas, and offers a comfortable walking surface on mezzanines and catwalks. Its non-sparking, non-conductive properties add safety in electrically sensitive zones and near flammable vapors.

- Competitive advantages include corrosion resistance versus steel, reduced noise, integrated slip resistance, and lighter weight for faster installation and easier retrofits.

- Use cases range from wastewater treatment skids and chemical dosing platforms to mixing stations, curing rooms, and outdoor access ways where closed surfaces are preferred.

- Zhaojia Composites Co., Ltd leverages deep fabrication know-how—cut-to-size panels, edge banding, fastening kits, and tailored resin systems—so B2B decision makers receive made-to-spec covered grating that accelerates projects and minimizes field rework.

Cost, Maintenance & User Experience

Total cost of ownership is where covered grating excels. Because FRP is inherently corrosion resistant, owners avoid recurrent painting, galvanizing touch-ups, and shutdowns for rust remediation. Lightweight panels reduce lifting equipment needs and speed installation, cutting downtime costs. Over the lifecycle, these savings translate into strong ROI compared with traditional steel plate on bar grating—especially in corrosive, wet, or hygienic environments common to building-material and component manufacturing.

- Durability: Grit-top surfaces maintain slip resistance; closed tops keep lines cleaner, reducing housekeeping labor. FRP’s dielectric nature adds operator safety.

- Customer feedback: Plants report fewer surface-related slip incidents, easier spill containment, and cleaner production zones versus open grating; maintenance teams appreciate simple wash-down and minimal corrosion checks.

Sustainability & Market Trends in manufacturing

Sustainability targets in industrial construction favor materials that last longer, reduce maintenance chemicals, and lower transport emissions. Covered grating supports these goals through extended service life, no need for solvent-based coatings, and reduced weight compared to metallic alternatives. As safety and compliance standards elevate expectations for slip resistance and worker protection, demand is expanding in both greenfield and retrofit projects across global manufacturing hubs.

- Regulatory momentum around safe walking-working surfaces and chemical exposure control continues to raise the bar for platforms and access systems—areas where covered grating’s closed, anti-slip design performs strongly.

- Positioned as a forward-thinking FRP grating manufacturer, Zhaojia Composites Co., Ltd emphasizes quality resins, precise layups, and fabrication efficiency to deliver durable components that align with modern ESG and safety priorities.

Conclusion on Covered Grating from Zhaojia Composites Co., Ltd

Covered grating provides a reliable, closed-top, slip-resistant surface engineered for the realities of modern manufacturing—especially within building materials production and non-metallic structural components for construction. By combining corrosion resistance, easy maintenance, and fast installation, it helps B2B teams improve uptime and safety while lowering lifecycle costs. As a specialized FRP grating manufacturer, Zhaojia Composites Co., Ltd delivers consistent quality and project-ready fabrication that simplifies execution.

- Explore how a tailored grating cover can elevate your next project’s performance and safety.

- Contact us: email: admin@zjcomposites.com - Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025