loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp grating installation

Installation of FRP Grating A Comprehensive Guide

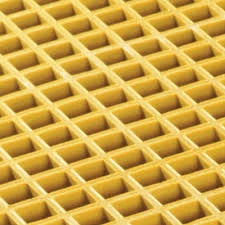

FRP (Fiber Reinforced Polymer) grating is widely recognized for its strength, durability, and resistance to corrosive environments. It is an ideal choice for various applications, including walkways, industrial flooring, and platforms. The installation of FRP grating requires careful planning and execution to ensure maximum performance and longevity. This article provides a detailed guide to installing FRP grating, highlighting essential steps and considerations.

Preparation and Planning

Before beginning the installation, it is vital to assess the site and gather all necessary materials and tools. The first step is to examine the location where the grating will be installed. Check for any obstacles, uneven surfaces, or existing infrastructure that may impact the installation process. Taking accurate measurements is crucial to determine the quantity of FRP grating needed.

Additionally, select the appropriate type of grating for your specific application. FRP grating comes in various sizes, colors, and resin formulations. Depending on the environment—whether it be marine, industrial, or chemical—you may need to choose a particular type of resin that offers enhanced corrosion resistance.

Tools and Materials

Ensure you have the right tools ready before you start the installation. Generally, the following tools and materials will be needed

- FRP grating panels - Cutting tools (diamond blade saw or similar) - Measuring tape - Level - Drill and drill bits - Fasteners (screws, bolts, and anchors as appropriate) - Personal Protective Equipment (PPE) including gloves and safety goggles

Installation Steps

frp grating installation

1. Create a Framework Start by constructing a robust framework or substructure that will support the FRP grating. The framework, usually made from metal or wood, should be designed to bear the load requirements of the grating. Ensure that the frame is level and secure, allowing for appropriate drainage if necessary.

2. Cutting the Grating If your grating panels need to be modified to fit the installation area, carefully measure and cut them using a proper cutting tool. It is essential to wear protective gear when cutting to avoid injury. Make sure to smooth the cut edges to eliminate any sharp points that could pose a hazard.

3. Placing the Grating Lay the FRP grating panels onto the framework. Ensure that they fit snugly and are aligned properly with minimal gaps between them. Depending on the design and load requirements, some panels might need to be staggered for better support.

4. Securing the Grating Once positioned, secure the grating using appropriate fasteners. Drill holes in the grating and attach them to the framework with screws or bolts, following the manufacturer's guidelines for spacing and load specifications. This ensures that the grating will remain stable and secure under foot traffic or other loads.

5. Final Inspection After the grating is installed and secured, conduct a final inspection to check for any loose fittings or irregularities. Ensure that all fasteners are tight and that the grating is level. Look for any potential hazards, such as sharp edges or protruding fasteners, and address them appropriately.

Maintenance Considerations

Although FRP grating is designed to be low-maintenance, it is essential to conduct periodic inspections to spot any signs of wear or damage. Cleaning the grating regularly will help prevent the build-up of debris and ensure safe usage.

In conclusion, installing FRP grating can be a straightforward process when approached methodically. By following these steps and considering all necessary precautions, you can create a safe and durable solution for your flooring needs. Whether in industrial sites, walkways, or commercial applications, properly installed FRP grating provides both functionality and longevity.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025