loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp structural shapes

Understanding FRP Structural Shapes Innovations in Modern Construction

Fiber Reinforced Polymer (FRP) has emerged as a groundbreaking material in the construction industry, particularly for structural shapes. With its unique properties and advantages, FRP is reshaping how engineers and architects approach design and construction. This article explores the significance of FRP structural shapes, their applications, advantages, and the future trends in the industry.

What is FRP?

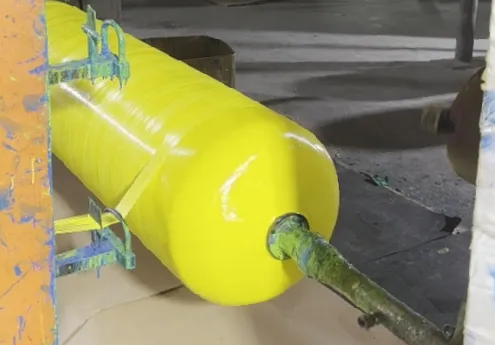

FRP is a composite material made from a polymer matrix reinforced with fibers. The most common types of fibers used in FRP are glass, carbon, and aramid. The combination of these fibers with a resin matrix results in a material that exhibits high strength-to-weight ratios, corrosion resistance, and durability. These attributes have made FRP an attractive option for various structural applications.

Applications of FRP Structural Shapes

FRP structural shapes are utilized in a wide array of applications across different sectors, including civil engineering, marine construction, and aerospace. In civil engineering, FRP is increasingly used for beams, columns, and panels, providing lightweight and durable alternatives to traditional steel and concrete structures. Its corrosion resistance makes it particularly useful for infrastructures subjected to harsh environments, such as bridges and marine facilities.

In the marine sector, FRP structural shapes are ideal for shipbuilding and offshore platforms. They offer significant advantages over traditional materials by reducing weight, which enhances fuel efficiency and performance. Additionally, FRP’s resistance to chemical exposure makes it suitable for environments such as oil rigs and wastewater treatment facilities.

Advantages of FRP Structural Shapes

1. Lightweight One of the most significant advantages of FRP is its lightweight nature. Structures built with FRP can reduce overall construction weight, allowing for easier handling, transportation, and installation. This property can lower transportation costs and accelerate project timelines.

frp structural shapes

2. Corrosion Resistance Unlike steel, which can rust and deteriorate when exposed to moisture and environmental elements, FRP materials do not corrode. This makes them ideal for applications in corrosive environments, reducing maintenance costs and extending the lifespan of structures.

3. High Strength-to-Weight Ratio FRP boasts a high strength-to-weight ratio, allowing for the construction of strong yet lightweight structures. This feature not only improves structural performance but also enables innovative architectural designs that were previously impossible with traditional materials.

4. Sustainability As the construction industry increasingly prioritizes sustainability, FRP materials offer environmental benefits. Many FRP products are made from recyclable materials, and their durability helps reduce the need for frequent replacements, contributing to a lower carbon footprint over time.

5. Thermal and Electrical Insulation FRP provides excellent thermal and electrical insulation, making it suitable for specific applications where these properties are essential, such as electrical poles and railways.

Future Trends

The future of FRP structural shapes appears promising, with continuous advancements in material technology and manufacturing processes. Innovations such as hybrid composites, which combine different types of fibers, are being explored to enhance performance further. Additionally, the development of automated manufacturing techniques, such as 3D printing, is expected to increase efficiency and reduce costs in FRP production.

Moreover, as regulatory bodies recognize the benefits of FRP, we can expect to see an increase in code approvals for its use in a wider variety of applications. This acceptance will drive research and development, leading to even more innovative uses and enhancements in structural design.

Conclusion

FRP structural shapes represent a significant advancement in construction materials, offering numerous benefits over traditional options. Their lightweight, corrosion-resistant, and strong nature makes them ideal for various applications, paving the way for more sustainable and innovative designs. As technology continues to evolve, FRP is likely to play an increasingly vital role in shaping the future of construction, revolutionizing the way we build and design our world. The embrace of FRP in structural engineering represents not just a shift in material choice but a profound change in how we approach the challenges of modern construction.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025