loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Fev . 15, 2025 05:30

Back to list

frp vessel for water treatment

Exploring the world of construction materials, one cannot overlook the evolution of reinforcing bars, especially the innovative FRP (Fiber Reinforced Polymer) reinforcement bars. These high-performance alternatives to traditional steel rebar have gained significant traction in various infrastructure projects globally. Implementing FRP reinforcement bars offers several advantages that align with modern construction demands for durability, sustainability, and reduced maintenance.

Expert opinions praise FRP reinforcement for its lifecycle longevity and reduced environmental impact. Unlike steel production, which is energy-intensive and emits significant CO2, the manufacture of FRP involves fewer emissions, aligning with global sustainability goals. An environmental engineer with expertise in sustainable construction advocates for the broader adoption of FRP bars, pointing to a study that demonstrates their lower carbon footprint over a 50-year infrastructure lifespan. Regarding authoritativeness, industry standards and certifications for FRP reinforcement bars are well established. Compliance with these standards ensures quality and reliability, as attested by leading construction firms who prioritize using certified FRP products. The growing body of research and academic endorsements further solidifies the standing of FRP bars in the construction sector. In terms of trustworthiness, the installed base of FRP-reinforced structures provides ample empirical data for performance evaluation. Consistent performance feedback from diverse geographical and climatic installations bolsters confidence in FRP technology among stakeholders. Overall, FRP reinforcement bars represent a forward-thinking approach to construction that addresses key industry challenges, offers unmatched benefits over traditional materials, and encapsulates the essence of modern engineering. Their integration into various projects worldwide underscores their growing significance in building robust, durable, and sustainable infrastructures for the future.

Expert opinions praise FRP reinforcement for its lifecycle longevity and reduced environmental impact. Unlike steel production, which is energy-intensive and emits significant CO2, the manufacture of FRP involves fewer emissions, aligning with global sustainability goals. An environmental engineer with expertise in sustainable construction advocates for the broader adoption of FRP bars, pointing to a study that demonstrates their lower carbon footprint over a 50-year infrastructure lifespan. Regarding authoritativeness, industry standards and certifications for FRP reinforcement bars are well established. Compliance with these standards ensures quality and reliability, as attested by leading construction firms who prioritize using certified FRP products. The growing body of research and academic endorsements further solidifies the standing of FRP bars in the construction sector. In terms of trustworthiness, the installed base of FRP-reinforced structures provides ample empirical data for performance evaluation. Consistent performance feedback from diverse geographical and climatic installations bolsters confidence in FRP technology among stakeholders. Overall, FRP reinforcement bars represent a forward-thinking approach to construction that addresses key industry challenges, offers unmatched benefits over traditional materials, and encapsulates the essence of modern engineering. Their integration into various projects worldwide underscores their growing significance in building robust, durable, and sustainable infrastructures for the future.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

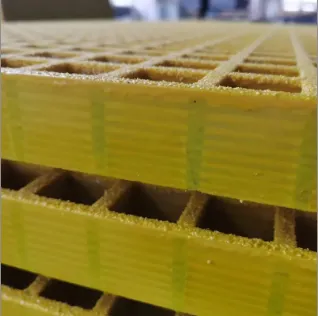

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025