loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Yan . 13, 2025 15:39

Back to list

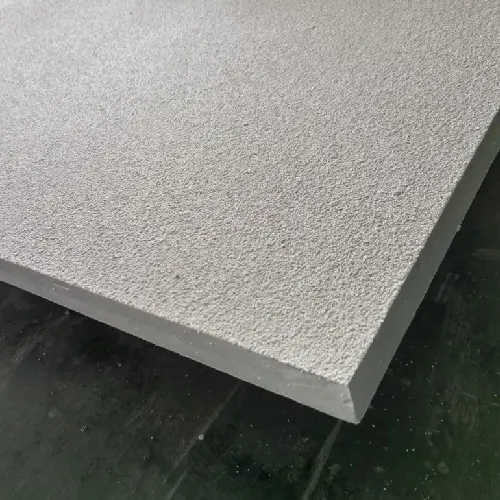

fibreglass grating price

Fibreglass grating is a versatile and durable product that finds extensive applications across diverse industries. This powerful material, known for its strength, longevity, and resistance to environmental factors, is especially valued in industries like maritime, chemical processing, and infrastructure projects. Yet, when exploring the fibreglass grating market, companies and project managers often have a common concern what factors influence its pricing?

Market conditions and supply chain elements also play a considerable role in fibreglass grating pricing. Global events, economic fluctuations, or changes in resin prices can affect supply and demand dynamics. Therefore, staying informed about the broader market trends can offer advantages in anticipating cost changes and securing better contracts. In terms of expertise, engaging with reputable suppliers who have established records of quality and reliability is critical. Suppliers with extensive industry experience are not only more likely to provide high-quality products but also offer additional services such as consulting, installation guidance, and after-sales support, ensuring the success and longevity of your project. Trust plays a vital role as well. Given the broad range of suppliers and the complexity of product specifications, ensuring that your supplier offers transparent pricing without hidden costs and stands by their product with robust warranties or guarantees is crucial in mitigating risks associated with long-term investments. Ultimately, the price of fibreglass grating is a reflection of multiple intersecting factors, including material quality, manufacturing technique, customization options, and prevailing market conditions. By understanding these elements, industry professionals can make decisions grounded in experience, expertise, and market authority, ensuring cost-effective and outcome-driven procurement. Always undertake thorough research, evaluate your project’s specific needs, and align them with what the market offers to achieve an optimal balance of cost and quality in fibreglass grating investments.

Market conditions and supply chain elements also play a considerable role in fibreglass grating pricing. Global events, economic fluctuations, or changes in resin prices can affect supply and demand dynamics. Therefore, staying informed about the broader market trends can offer advantages in anticipating cost changes and securing better contracts. In terms of expertise, engaging with reputable suppliers who have established records of quality and reliability is critical. Suppliers with extensive industry experience are not only more likely to provide high-quality products but also offer additional services such as consulting, installation guidance, and after-sales support, ensuring the success and longevity of your project. Trust plays a vital role as well. Given the broad range of suppliers and the complexity of product specifications, ensuring that your supplier offers transparent pricing without hidden costs and stands by their product with robust warranties or guarantees is crucial in mitigating risks associated with long-term investments. Ultimately, the price of fibreglass grating is a reflection of multiple intersecting factors, including material quality, manufacturing technique, customization options, and prevailing market conditions. By understanding these elements, industry professionals can make decisions grounded in experience, expertise, and market authority, ensuring cost-effective and outcome-driven procurement. Always undertake thorough research, evaluate your project’s specific needs, and align them with what the market offers to achieve an optimal balance of cost and quality in fibreglass grating investments.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025