loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Fev . 15, 2025 11:50

Back to list

chs steel tube

For businesses and engineers working in construction, automotive, and mechanical industries, selecting the right material is crucial for the durability and effectiveness of their projects. Behind the scenes of many successful projects is a material that often goes unnoticed but plays an essential role—CHS (Circular Hollow Section) steel tubes. These steel tubes offer a blend of strength, versatility, and cost-effectiveness that meets the rigorous demands of modern engineering and construction.

Trustworthiness in construction materials is non-negotiable, and CHS steel tubes deliver on this front through their compliance with international standards and testing. Certifications from recognized entities reassure engineers and architects of their quality and performance. For instance, many CHS steel tubes are produced to ASTM standards, assuring their mechanical properties and dimensional accuracy. The authority of CHS steel tubes in the market is underpinned by years of research, innovation, and development. Manufacturers invest in technological advancements, such as improved metallurgical processes and corrosion-resistant coatings. This continuous improvement cycle ensures that the tubes not only meet current industry standards but also anticipate future needs, thus reinforcing their standing. For anyone considering CHS steel tubes, real-world experience testifies to their efficacy. Case studies abound where these tubes have surpassed expectations, such as in rapid-build scenarios where time and efficiency dictate success. Projects that leverage the unique properties of CHS steel tubes often report enhanced performance, longevity, and client satisfaction, reinforcing their reputation as a material of choice. To sum up, the decision to use CHS steel tubes in a project should be informed by their proven benefits. Their structural strength, versatility, compliance with global standards, and aesthetic appeal make them an unparalleled choice for engineers and architects striving for optimal results. As industries continue to evolve with a focus on sustainability and innovation, CHS steel tubes will undoubtedly maintain their pivotal role in platforms where reliability is essential.

Trustworthiness in construction materials is non-negotiable, and CHS steel tubes deliver on this front through their compliance with international standards and testing. Certifications from recognized entities reassure engineers and architects of their quality and performance. For instance, many CHS steel tubes are produced to ASTM standards, assuring their mechanical properties and dimensional accuracy. The authority of CHS steel tubes in the market is underpinned by years of research, innovation, and development. Manufacturers invest in technological advancements, such as improved metallurgical processes and corrosion-resistant coatings. This continuous improvement cycle ensures that the tubes not only meet current industry standards but also anticipate future needs, thus reinforcing their standing. For anyone considering CHS steel tubes, real-world experience testifies to their efficacy. Case studies abound where these tubes have surpassed expectations, such as in rapid-build scenarios where time and efficiency dictate success. Projects that leverage the unique properties of CHS steel tubes often report enhanced performance, longevity, and client satisfaction, reinforcing their reputation as a material of choice. To sum up, the decision to use CHS steel tubes in a project should be informed by their proven benefits. Their structural strength, versatility, compliance with global standards, and aesthetic appeal make them an unparalleled choice for engineers and architects striving for optimal results. As industries continue to evolve with a focus on sustainability and innovation, CHS steel tubes will undoubtedly maintain their pivotal role in platforms where reliability is essential.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

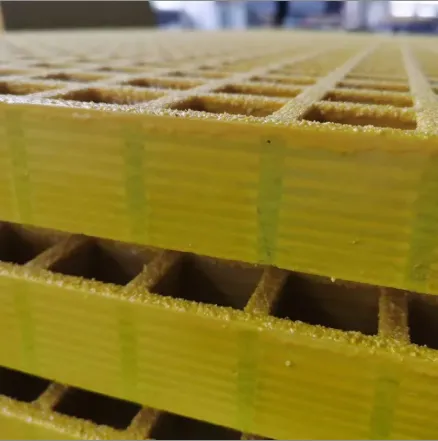

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025