loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

The Unseen Engine Beneath Your Feet Mini Mesh Grating

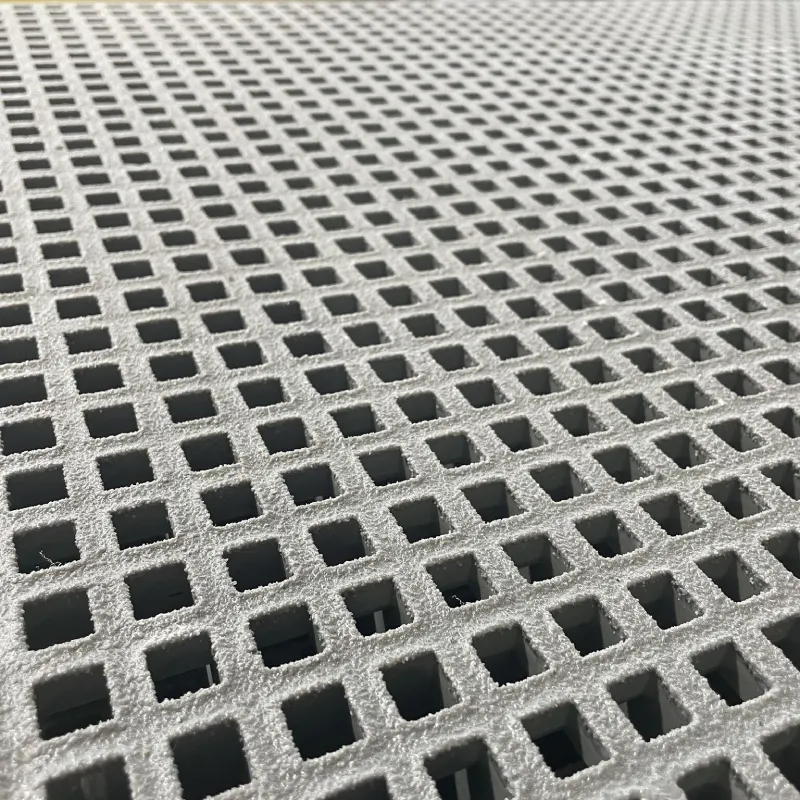

In the complex landscape of industrial specification and architectural design, the selection of underlying infrastructure often determines a project's long-term viability and safety performance. ZJ Composites introduces a critical solution engineered for environments where standard grating geometries present unacceptable risks—our advanced mini mesh grating system. This product represents a fundamental re-engineering of traditional grid patterns, specifically developed to address the challenge of containing smaller objects while maintaining all the renowned benefits of composite materials. The grp mini mesh grating we supply to our global wholesale partners embodies our core principle of "Better Composites, Better than Metal," delivering certified safety performance that meets rigorous international standards including BS EN 14122 Category B and the European 20mm Ball Falling Test requirement. This commitment to engineered excellence reflects our mission of revolutionizing composite materials through premium innovation, providing distributors with a technically superior product that builds client trust and fosters lasting brand loyalty through demonstrable performance in the field.

Precision Engineering in Mini Mesh Grating

The technological distinction of ZJ Composites' mini mesh decking lies in its mathematically optimized grid configuration, which reduces open space while maintaining structural integrity and drainage capabilities. This deliberate design transformation from conventional grating patterns creates a secure surface that prevents the passage of items that would otherwise fall through standard grids, addressing a significant safety concern across multiple industries. Our manufacturing process employs state-of-the-art pultrusion technology under strictly controlled parameters, ensuring consistent dimensional accuracy and mechanical properties throughout every production run. The frp mini mesh undergoes rigorous quality verification using our advanced testing equipment, with specialized technicians conducting methodical inspections to guarantee compliance with documented specifications. This systematic approach to manufacturing excellence ensures that our wholesale partners receive a product of uncompromising quality that performs precisely as engineered, project after project.

Diverse Applications for Mini Mesh Decking Systems

The unique characteristics of mini mesh decking make it an ideal solution across numerous industries where safety, durability, and specialized performance are paramount. In marine and waterfront applications, our grp mini mesh grating provides secure walking surfaces on docks, piers, and offshore platforms where traditional grating would allow small tools and equipment to fall into the water. The corrosion-resistant properties ensure long-term performance in saltwater environments where steel grating would rapidly deteriorate. The architectural and construction sectors increasingly specify mini mesh decking for high-profile projects requiring both safety and aesthetic appeal, including public walkways, transportation hubs, and commercial atriums where the fine mesh pattern provides security without visual obstruction. Industrial facilities with sensitive operational requirements—including food processing plants, pharmaceutical manufacturing areas, and electronic cleanrooms—utilize frp mini mesh for its non-shedding, non-corrosive properties that maintain strict hygiene standards. The infrastructure sector deploys these systems in utility tunnels, water treatment walkways, and electrical substation platforms where the material's dielectric properties provide essential worker protection. This diverse application spectrum demonstrates our commitment to developing engineered solutions that address specific operational challenges across global markets.

Performance Characteristics of Modern Mesh Solutions

The material advantages of ZJ Composites' frp mini mesh create compelling value propositions for wholesalers and their clients across multiple dimensions of performance. The composite construction delivers inherent corrosion immunity, completely eliminating rust-related degradation even in aggressive chemical environments or saltwater applications that rapidly destroy metallic alternatives. This chemical resistance translates directly to reduced lifetime costs through the elimination of protective coatings and associated maintenance, while the lightweight nature of the material significantly simplifies installation logistics and reduces structural support requirements. The manufactured surface of mini mesh grating provides consistent slip resistance under various conditions, enhancing workplace safety while the non-conductive properties protect against electrical hazards. These technical attributes combine to create a product that outperforms traditional materials on both operational and economic metrics, delivering the superior value proposition that underpins our brand promise of better composites.

Collaborative Partnership for Distribution Excellence

Engaging with ZJ Composites for your mini mesh grating requirements establishes a collaborative relationship built upon mutual success and shared objectives. Our organizational architecture uniquely positions us to support wholesale partners through two specialized teams working in concert—production specialists ensuring product excellence through meticulous quality control processes, and customer service professionals with international experience providing responsive support and technical guidance. This dual-capability structure ensures that our partners receive not only premium products but also comprehensive service throughout the procurement and implementation process. We maintain an active feedback system that continuously gathers insights from our distribution network, enabling ongoing product refinement and service enhancement aligned with market evolution. This partnership philosophy, centered on achieving win-win outcomes through quality products and thoughtful service, forms the foundation of our approach to cultivating enduring business relationships.

Mini Mesh Grating FAQ

What specific safety validation does your mini mesh grating possess?

Our mini mesh grating is formally validated to comply with BS EN 14122 Category B safety standards and successfully passes the 20mm Ball Test requirement, providing certified fall-through protection.

In which project scenarios does grp mini mesh grating deliver particular advantage?

Grp mini mesh grating provides distinct advantages in marine applications, architectural features, utility plants, and any setting requiring both safety containment and corrosion resistance.

How does frp mini mesh withstand harsh environmental conditions?

Frp mini mesh maintains structural integrity in harsh conditions through complete corrosion immunity, UV-resistant formulations, and material stability across temperature variations.

What load capacity can be expected from mini mesh decking installations?

Our mini mesh decking delivers substantial load-bearing capacity suitable for pedestrian traffic, equipment areas, and many industrial applications, with specific engineering data available for project planning.

What technical support accompanies orders for mini mesh grating?

We provide comprehensive technical support including specification guidance, installation recommendations, and project-specific engineering data to ensure successful implementation of mini mesh grating.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025