loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

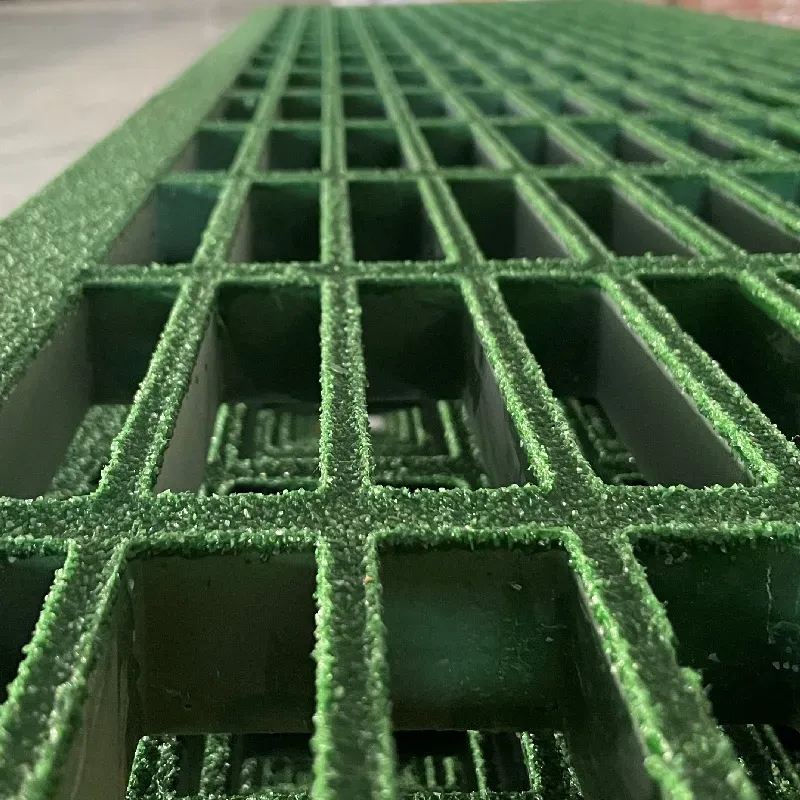

grp open mesh grating

The Importance of GRP Open Mesh Grating in Modern Applications

In recent years, the demand for advanced and versatile building materials has surged as industries strive for efficiency, safety, and durability. One such innovative material that has garnered significant attention is Glass Reinforced Plastic (GRP) open mesh grating. This composite material is becoming increasingly popular in various sectors, including construction, chemical processing, wastewater treatment, and even marine environments, due to its unique properties and advantages.

GRP open mesh grating consists of a grating structure made from fiberglass, reinforced with resin, that allows for a lightweight yet robust solution for flooring, walkways, and platforms. Its open design promotes excellent drainage while reducing surface water accumulation. One of the standout features of GRP grating is its non-corrosive nature—contrasted with traditional metal grating, which is prone to rust and deterioration over time. This property makes GRP ideal for environments that are exposed to moisture and chemicals, significantly extending the lifespan of the installations.

The Importance of GRP Open Mesh Grating in Modern Applications

Another crucial advantage of GRP open mesh grating is its versatility in design. Manufacturers can produce grating in different sizes, colors, and load capacities, catering to specific requirements. It can be customized to fit unique architectural features and functional needs, making it suitable for diverse applications—from pedestrian walkways to heavy-duty industrial platforms. The material can easily adapt to various load demands, providing solutions for both light and heavy traffic areas.

grp open mesh grating

In addition, GRP open mesh grating is environmentally friendly. During its production, it can be designed to use less energy compared to traditional materials. Moreover, its longevity reduces the frequency of replacements and maintenance, resulting in a lower environmental impact over time. GRP products are also fully recyclable, making them a sustainable choice for eco-conscious industries and consumers.

The applications of GRP open mesh grating are extensive. In marine environments, for instance, it serves as an excellent solution for docks and piers where saltwater corrosion is a concern. In chemical processing plants, GRP grating is used in areas where spills may occur, ensuring safety and efficiency in hazardous environments. Additionally, in municipal water treatment facilities, GRP’s resistance to harsh chemicals makes it a preferred choice for walkways and platforms.

Moreover, sectors involved in food production benefit significantly from GRP grating. It can be used in processing plants because it does not harbor bacteria, is easy to clean, and maintains a hygienic environment essential for food safety. Its non-absorbent surface prevents any contamination, making it ideal for industries where hygiene standards are critical.

In conclusion, GRP open mesh grating presents a wealth of advantages that cater to various industries’ needs, including durability, safety, and versatility. As businesses look towards more sustainable and efficient building materials, the relevance of GRP continues to grow. Its innovative properties not only enhance workplace safety and operational efficiency, but also promote environmental stewardship. As we advance into a future that increasingly prioritizes sustainability and safety in construction and industrial applications, GRP open mesh grating stands out as an essential solution that meets the demanding challenges of modern environments.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025