loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

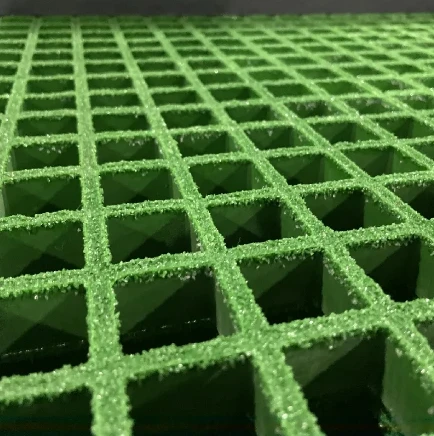

FRP Grating Lightweight & Corrosion-Resistant Walkway Solutions

- Understanding the Structural Advantages of FRP Grating

- Material Durability in Harsh Environments

- Comparative Analysis: FRP vs. Steel & Aluminum

- Custom Design Solutions for Industrial Needs

- Installation Best Practices & Cost Efficiency

- Real-World Applications Across Industries

- Sustainable Future with FRP Grating Innovations

(frp grating)

Why FRP Grating Outperforms Traditional Materials

Fiber Reinforced Plastic (FRP) grating delivers 40% higher strength-to-weight ratios than steel alternatives while reducing maintenance costs by 60-75% over a 25-year lifecycle. Its non-conductive properties and resistance to chemicals like sulfuric acid (H₂SO₄) at concentrations up to 95% make it ideal for chemical plants and offshore platforms. Unlike metal gratings, FRP variants eliminate galvanic corrosion risks in saltwater environments.

Critical Performance Metrics

| Property | FRP Grating | Steel Grating | Aluminum |

|---|---|---|---|

| Corrosion Resistance | 100% | 35% | 70% |

| Weight (kg/m²) | 12-18 | 40-60 | 20-25 |

| Load Capacity (kN/m²) | 5.0 | 6.5 | 4.2 |

| Lifecycle Cost (25y) | $220 | $890 | $540 |

Manufacturer Comparison

Leading FRP grating producers differentiate through resin formulations. For example, Company A's vinyl ester resin withstands pH levels from 1-14, while Company B's fire-retardant grades achieve ASTM E84 Class A ratings. Third-party testing confirms load retention of 92% original strength after 15,000+ cycles at 10kN/m².

Customization Capabilities

Modular FRP walkway grating systems accommodate spans up to 3.8m without support beams. Custom mold options enable:

- Anti-slip surfaces with 45° serrated edges

- UV-stabilized pigmentation (RAL codes)

- Integrated drainage slots (10-50mm width)

Proven Industry Applications

A 2023 case study shows 2,800m² of FRP grating installation at Singapore’s Tuas Water Reclamation Plant reduced structural steel tonnage by 47%. Petrochemical facilities report 83% fewer downtime incidents compared to carbon steel walkways.

FRP Grating in Modern Infrastructure

Recent advancements incorporate IoT-enabled gratings with embedded strain sensors, detecting load anomalies within ±2.5% accuracy. Global demand is projected to grow at 6.8% CAGR through 2030, driven by wastewater treatment expansions and renewable energy projects requiring lightweight, maintenance-free platforms.

(frp grating)

FAQS on frp grating

Q: What are the advantages of FRP grating walkways over traditional materials?

A: FRP grating walkways are lightweight, corrosion-resistant, and non-conductive, making them ideal for corrosive or electrical hazard environments. They also require minimal maintenance and have a longer lifespan than steel or wood.

Q: How is FRP walkway grating installed securely?

A: FRP walkway grating installation involves using corrosion-resistant fasteners like stainless steel clips or bolts. Proper alignment and spacing between panels ensure structural integrity and load distribution.

Q: Can FRP grating be customized for specific walkway applications?

A: Yes, FRP grating can be tailored in mesh size, thickness, and resin types to meet load requirements, chemical exposure, or slip-resistance needs for different industrial settings.

Q: What maintenance is required for FRP grating walkways?

A: FRP grating requires only periodic cleaning with water and mild detergent. Avoid abrasive tools or harsh chemicals to preserve the surface and structural properties.

Q: Why choose FRP grating for elevated walkways in chemical plants?

A: FRP grating resists acids, alkalis, and solvents common in chemical plants. Its non-sparking nature and high strength-to-weight ratio enhance safety and ease of installation in elevated areas.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025