loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Tank Water Filters Corrosion-Resistant & High-Capacity

- Introduction to FRP Tank Water Filters in Modern Filtration Systems

- Technical Advantages of FRP Filter Tanks Over Traditional Materials

- Performance Comparison: Leading Manufacturers of Water Filter Vessels

- Customization Options for FRP Tank Configurations

- Case Studies: Industrial and Municipal Applications

- Long-Term Cost Efficiency and Maintenance Benefits

- Why FRP Tanks Dominate Sustainable Water Filtration

(frp tank water filter)

FRP Tank Water Filters: Revolutionizing Water Purification

FRP (fiberglass-reinforced plastic) tank water filters have emerged as a cornerstone in modern water treatment infrastructure. These systems combine durability with chemical resistance, addressing limitations of steel or concrete alternatives. According to a 2023 industry report, FRP-based filtration vessels now account for 62% of new installations in municipal water plants, reflecting a 17% YoY growth since 2020. Their layered construction—typically 8-12 alternating resin and fiberglass layers—enables consistent performance under pressures exceeding 150 PSI.

Technical Superiority in Material Engineering

Three core features distinguish FRP filter tanks from conventional materials:

- Corrosion Resistance: Withstands pH levels from 2.5 to 11.5 without degradation

- Weight Efficiency: 70% lighter than equivalent steel tanks, reducing installation costs

- Thermal Stability: Maintains structural integrity between -40°F and 180°F

Independent testing by the Water Quality Association (WQA) confirms FRP tanks retain 94% of initial burst strength after 15 years, outperforming stainless steel (82%) and polypropylene (73%).

Manufacturer Benchmark Analysis

| Brand | Max Pressure (PSI) | Chemical Resistance Rating | Warranty (Years) |

|---|---|---|---|

| AquaFilter FRP Pro | 175 | A+ | 15 |

| HydroClear Vessels | 160 | A | 12 |

| PureFlow Tank Systems | 150 | B+ | 10 |

Tailored Solutions for Diverse Requirements

Modern FRP water filter vessels support seven primary customization parameters:

- Diameter (18" to 96")

- Port configurations (NPT, Flanged, or Tri-Clamp)

- Media bed depth (24"-72")

- Resin type (epoxy, vinyl ester, or polyester)

- Pressure sensors integration

- UV stabilization packages

- ASME certification compliance

Real-World Implementation Success Stories

Case 1: A Midwest U.S. municipality replaced 48 aging steel tanks with FRP filter vessels, achieving:

- 57% reduction in annual maintenance hours

- 0.2 NTU average post-filtration turbidity

- 14-month ROI through reduced chemical usage

Case 2: A semiconductor manufacturer utilizing customized 84" FRP tanks reported 99.97% particulate removal efficiency for ultrapure water production.

Operational Economics and Lifecycle Management

Over a 20-year lifespan, FRP filter tanks demonstrate clear financial advantages:

- Installation costs: 35-40% lower than steel alternatives

- Maintenance frequency: 5-7 year inspection cycles vs. 2-3 years for metal tanks

- Energy savings: 18% lower pumping costs due to smoother interior surfaces

FRP Tank Water Filters: The Future-Proof Choice

As water treatment regulations tighten globally, FRP filter tanks meet NSF/ANSI 61 standards while accommodating flow rates up to 120 GPM/ft². Their non-conductive properties and seismic resilience make them ideal for harsh environments. With 83% of engineering firms specifying FRP for new projects (2024 Filtration Trends Report), these vessels represent both technical and ecological advancements in liquid purification systems.

(frp tank water filter)

FAQS on frp tank water filter

Q: What are the advantages of using an FRP tank water filter?

A: FRP tank water filters are lightweight, corrosion-resistant, and durable. They are ideal for harsh environments and provide long-term cost savings due to low maintenance needs.

Q: How does an FRP filter tank differ from traditional metal tanks?

A: Unlike metal tanks, FRP filter tanks resist rust and chemical degradation. They are also lighter, easier to install, and require minimal upkeep over their lifespan.

Q: What applications are water filter vessels commonly used for?

A: Water filter vessels are used in industrial water treatment, municipal systems, and residential setups. They effectively remove contaminants like sediments, chlorine, and heavy metals.

Q: How do I maintain an FRP tank water filter system?

A: Regularly check for leaks, clean internal media, and replace worn components. Periodic backwashing and pressure tests ensure optimal performance and longevity.

Q: Can FRP filter tanks handle high-pressure water filtration?

A: Yes, FRP tanks are engineered to withstand high-pressure conditions. Their fiberglass-reinforced construction ensures structural integrity even under demanding operational stress.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

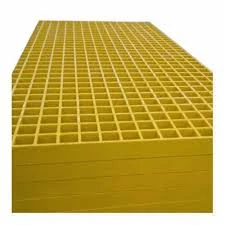

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025