loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Profiles: Lightweight, Corrosion-Resistant—Why Us?

Why FRP Profiles Are Replacing Steel In Tough Jobs

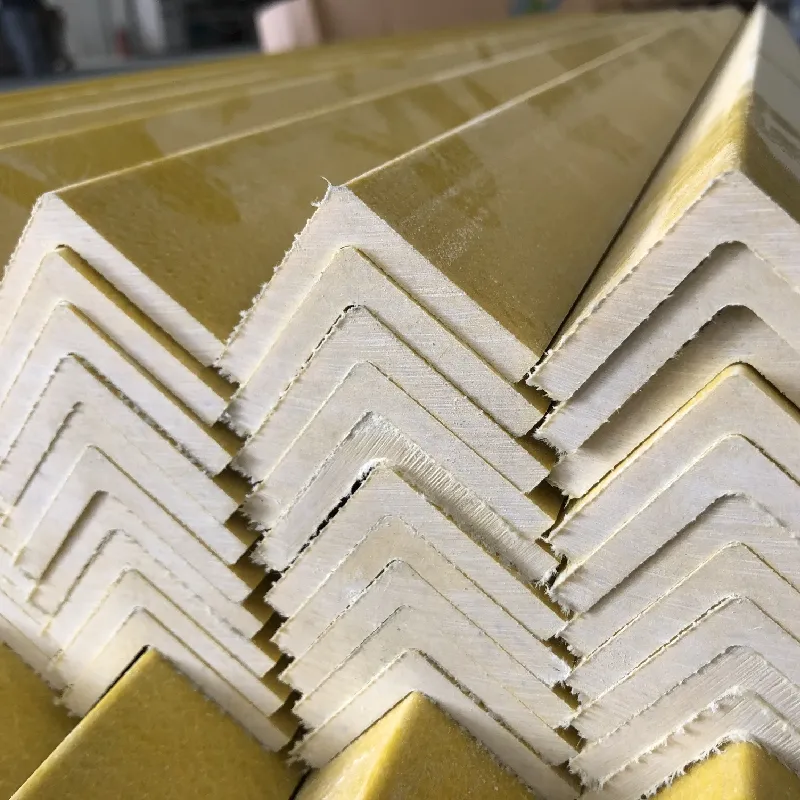

I’ve spent enough time on job sites to know: corrosion never sleeps. That’s why frp profiles are showing up everywhere—from coastal walkways to chemical plants. The High Strength FRP Pultruded Profile Fiberglass I Beam for Construction from ZJ Composites feels like the category distilled: strong, predictable, and surprisingly easy to work with. And yes, lighter than the guys expect the first time they lift an I-beam.

Industry trend check

Steel prices swing, maintenance budgets get cut, and uptime matters. A lot. That’s driving the shift to frp profiles in corrosive and remote sites. In fact, asset owners tell me their top triggers are: reduced repainting, faster install (no hot works, fewer lifts), and design flexibility. Adoption started in wastewater and marine; now it’s crossing into light industrial frames, platforms, and even rooftop structures where weight penalties hurt.

What’s inside an FRP I-beam (and why it matters)

Pultrusion is the method: continuous E-glass roving + stitched mats pulled through a resin bath (polyester or vinyl ester), aligned in a heated die, then cured, pulled, cut, and finished. ZJ Composites runs routine QC—tensile/flexural per ASTM D638/D790, resin content (ASTM D2584), water absorption (ASTM D570), and flame spread per ASTM E84 when specified. Profiles can meet EN 13706 (E23/E17 classes) for structural performance. Real-world service life? Around 25–50 years depending on UV, chemistry, and loading. Not eternal, but better than a rusty column, to be honest.

Typical product specs (I-beam)

| Property | Test Method | Typical Value ≈ |

|---|---|---|

| Tensile Strength | ASTM D638 | 300 MPa |

| Flexural Strength | ASTM D790 | 400 MPa |

| Flexural Modulus | ASTM D790 | 20 GPa |

| Density | ASTM D792 | 1.8–1.9 g/cm³ |

| Water Absorption (24h) | ASTM D570 | ≤0.5% |

| Flame Spread | ASTM E84 | Class 1 (optional) |

| UV Protection | QUV | Gelcoat/veil + additive |

Where these beams earn their keep

- Wastewater plants: platforms, ladders, and structural skids.

- Marine/coastal: boardwalk frames, fender systems—salt spray is a non-issue.

- Chemical processing: acid/alkali areas where steel coatings fail.

- Power & telecom: rooftop frames, cable supports—no RF interference.

- Food plants: low maintenance, non-sparking, easy washdown.

Installers say field cuts with diamond blades are clean, and bolting through web/flange is straightforward. Honestly, it’s more “carpentry” than welding.

Vendor snapshot (why ZJ Composites is on shortlists)

| Vendor | Certs | Testing | Lead Time ≈ | Notes |

|---|---|---|---|---|

| ZJ Composites (Hebei, China) | ISO 9001 | In-house ASTM/EN 13706 | 2–4 weeks | Strong on custom pultrusion; address: No. 9, Xingyuan South St., Zaoqiang |

| Vendor A | ISO 9001, ISO 14001 | Third-party only | 4–6 weeks | Higher price tier |

| Vendor B | ISO 9001 | Basic mechanicals | 3–5 weeks | Limited resin options |

Customization, compliance, and real-world wins

Customizations include vinyl ester systems for harsh chemicals, E84 Class 1 fire-retardant grades, UV gelcoats, and non-standard I-beam dimensions. Engineers often request datasheets aligned to EN 13706 and load tables for quick checks. One wastewater retrofit we followed swapped corroded steel frames for frp profiles and cut maintenance visits by roughly 60% in the first 18 months; the plant manager told me “the silence of not grinding rust is the best KPI.”

Another case: a coastal boardwalk rebuild used these I-beams to dodge over-water welding permits—install finished two weeks earlier than planned. Not glamorous, but budgets like that.

Buying notes

- Ask for mechanicals with test methods, not just numbers.

- Confirm UV package and fire rating where code requires.

- Request sample cut/finish to validate surface quality and fiber alignment.

- For structural design, use vendor load tables or test your exact span. Real-world use may vary.

Bottom line: If corrosion is eating your capex, frp profiles are not a niche anymore—they’re a practical default.

Authoritative references

- ASTM D638, D790, D570, D2584, E84: Standard tests for FRP mechanicals, absorption, resin content, and flame spread.

- EN 13706: Reinforced plastics composites — Specifications for pultruded profiles.

- ISO 9001: Quality management systems for manufacturing control.

- ACI 440 guides: Design with fiber-reinforced polymer composites for structures.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025