loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Янв . 25, 2025 04:58

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

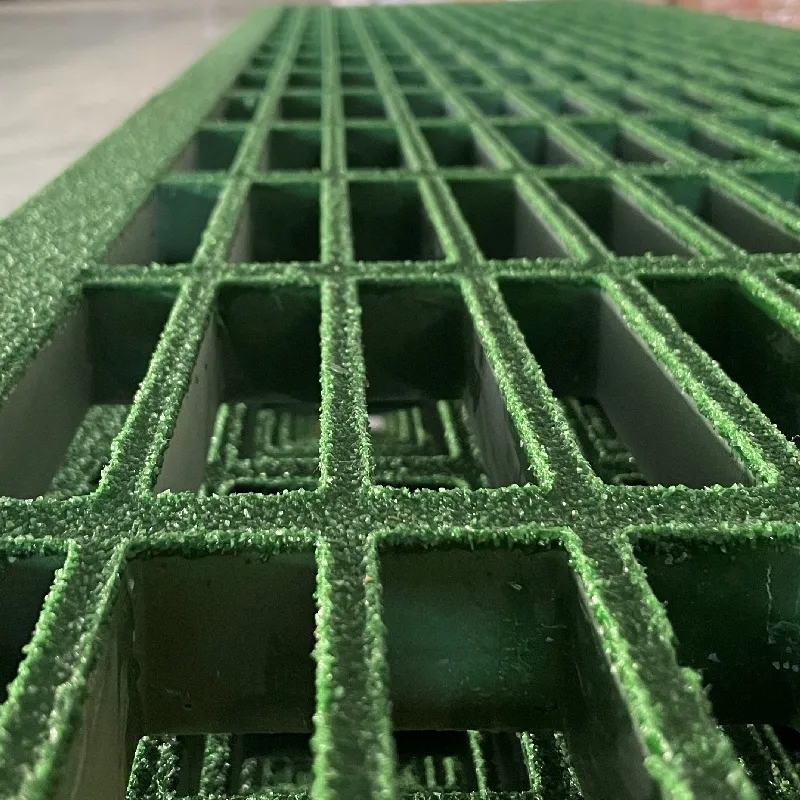

Fiberglass Reinforced Plastic (FRP) rectangular tubes have been gaining traction in various industries due to their unique properties and versatility. These composite materials offer solutions where traditional materials like wood, metal, or concrete fall short. This article delves into the realm of FRP rectangular tubes, focusing on the substantial benefits they provide, backed by expert opinions, user experiences, and their authoritative use in industry.

Moreover, the versatility and ease of fabrication associated with FRP rectangular tubes cannot be overstated. These materials can be easily molded and cut to fit specific design requirements, providing architects and designers with the creative freedom that traditional materials might restrict. This malleability, paired with the lightweight characteristic of FRP, facilitates easier transportation and installation, presenting a significant cost-saving advantage during large-scale projects. Construction professionals have repeatedly vouched for the time-efficiency and reduced labor costs observed when utilizing FRP rectangular tubes in comparison to metallic counterparts. In terms of environmental sustainability, FRP rectangular tubes are a favorable option. The manufacturing process of FRP involves less energy consumption compared to metal processing, contributing to lower carbon emissions. Additionally, innovations in the recycling of composite materials are paving the way for a more sustainable lifecycle of FRP products. Environmental experts advocate for the adoption of FRP materials for projects aiming to minimize their environmental footprint, thus adding another layer of trust in FRP's long-term viability. Despite the compelling advantages, some challenges with FRP rectangular tubes include the initial cost and limited awareness among certain industry sectors. However, as more case studies and successful implementations emerge, there is a growing acknowledgment of the cost-effectiveness of FRP over a project's lifecycle. This transition in perspective highlights the authoritative guidance provided by industry leaders who continue to educate and demonstrate the practical benefits of FRP rectangular tubes. In conclusion, FRP rectangular tubes present a blend of expertise, reliability, and innovation that aligns with the evolving demands of modern construction, infrastructure, and various specialized applications. Whether you’re an engineer, architect, or project manager, considering FRP rectangular tubes can lead to enhanced performance, sustained durability, and an overall reduction in the ecological footprint of your projects. As industries increasingly pivot towards sustainable and efficient materials, FRP stands out as a trustworthy choice backed by comprehensive expertise and proven results.

Moreover, the versatility and ease of fabrication associated with FRP rectangular tubes cannot be overstated. These materials can be easily molded and cut to fit specific design requirements, providing architects and designers with the creative freedom that traditional materials might restrict. This malleability, paired with the lightweight characteristic of FRP, facilitates easier transportation and installation, presenting a significant cost-saving advantage during large-scale projects. Construction professionals have repeatedly vouched for the time-efficiency and reduced labor costs observed when utilizing FRP rectangular tubes in comparison to metallic counterparts. In terms of environmental sustainability, FRP rectangular tubes are a favorable option. The manufacturing process of FRP involves less energy consumption compared to metal processing, contributing to lower carbon emissions. Additionally, innovations in the recycling of composite materials are paving the way for a more sustainable lifecycle of FRP products. Environmental experts advocate for the adoption of FRP materials for projects aiming to minimize their environmental footprint, thus adding another layer of trust in FRP's long-term viability. Despite the compelling advantages, some challenges with FRP rectangular tubes include the initial cost and limited awareness among certain industry sectors. However, as more case studies and successful implementations emerge, there is a growing acknowledgment of the cost-effectiveness of FRP over a project's lifecycle. This transition in perspective highlights the authoritative guidance provided by industry leaders who continue to educate and demonstrate the practical benefits of FRP rectangular tubes. In conclusion, FRP rectangular tubes present a blend of expertise, reliability, and innovation that aligns with the evolving demands of modern construction, infrastructure, and various specialized applications. Whether you’re an engineer, architect, or project manager, considering FRP rectangular tubes can lead to enhanced performance, sustained durability, and an overall reduction in the ecological footprint of your projects. As industries increasingly pivot towards sustainable and efficient materials, FRP stands out as a trustworthy choice backed by comprehensive expertise and proven results.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025