йөкләү ...

- No. 9, Синьцюан Көньяк урамы, Донгвайхуан юлы, Заокян округы, Хенгшуй, Хебей, Китай

- admin@zjcomposites.com

- +86 15097380338

- Безнең сайтка керергә рәхим итегез!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Инглиз

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

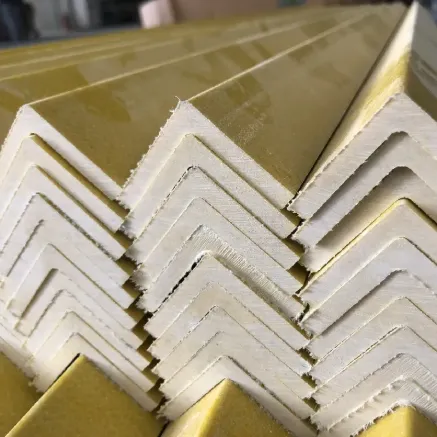

FRP Profiles: The Future of Strong and Durable Materials

Fiberglass Reinforced Polymer (FRP profiles) are a breakthrough in material science, offering superior strength, flexibility, and corrosion resistance compared to traditional materials like steel and aluminum. FRP profiles are widely used in construction, marine, automotive, and chemical industries due to their exceptional performance in extreme conditions. Unlike metals, FRP profiles do not corrode or degrade when exposed to water, chemicals, or harsh weather, making them an excellent choice for applications where longevity and reliability are key.

Manufactured using advanced pultrusion processes, FRP profiles are lightweight yet extremely strong, making them easy to transport and install. The material can be customized into various shapes and sizes, which allows it to meet the specific needs of any industry. Additionally, the high resistance to environmental factors like UV radiation, moisture, and temperature variations ensures that FRP profiles maintain their integrity for years. Whether it's for structural support, insulation, or aesthetic purposes, FRP profiles deliver unmatched durability, versatility, and cost-effectiveness.

FRP Pultruded Profiles: Perfect for Customized Applications

FRP pultruded profiles are made using a specialized process called pultrusion, where continuous fibers are pulled through a resin bath and then cured in a heated die. This process results in highly durable and customized shapes that offer superior strength-to-weight ratios. FRP pultruded profiles are widely used in a range of industries because they combine the best properties of fiberglass and polymer resins, such as excellent tensile strength, resistance to corrosion, and long-term durability.

The beauty of FRP pultruded profiles is their versatility. They can be produced in a wide range of shapes, including angles, channels, I-beams, and custom sections that are tailored to specific needs. Whether you are designing a structural component for a bridge, a railing for a commercial building, or a component for the automotive industry, FRP pultruded profiles provide the strength and flexibility required to handle demanding applications. Moreover, the pultrusion process allows for the creation of intricate designs and configurations that are not possible with traditional materials, making FRP pultruded profiles ideal for custom and specialized solutions.

FRP Pultruded Sections: Enhancing Structural Performance

FRP pultruded sections are an excellent choice for applications requiring strength, durability, and low maintenance. These sections can be made into various shapes such as beams, rods, tubes, and profiles, offering an ideal solution for industries ranging from construction to telecommunications. The key advantage of FRP pultruded sections is their ability to withstand extreme environmental conditions. They are highly resistant to corrosion, impact, and high temperatures, making them perfect for use in environments where traditional materials would degrade quickly.

In construction, FRP pultruded sections are used for support beams, decking, and other structural components. These sections provide superior load-bearing capabilities while being lightweight, which reduces the overall load on foundations and structures. FRP pultruded sections are also used in the marine industry for docks, piers, and boat building due to their resistance to seawater and their ability to perform under extreme pressure and weather conditions. This combination of performance and versatility makes FRP pultruded sections a valuable asset across many sectors.

Why Choose FRP Pultruded Profiles for Your Projects?

Choosing FRP pultruded profiles for your projects offers a range of benefits that make them an ideal alternative to traditional building materials. One of the key reasons why FRP pultruded profiles stand out is their remarkable strength-to-weight ratio. Despite being lightweight, FRP pultruded profiles are incredibly strong, making them easier to handle and install. Their resistance to rust, corrosion, and UV degradation also ensures they maintain their structural integrity and appearance for years, even in the most challenging environments.

Moreover, FRP pultruded profiles are customizable, allowing for a range of applications from industrial to architectural. Their non-conductive properties also make them ideal for electrical and telecommunications infrastructure, where grounding or electrical conductivity could pose a risk. The low thermal conductivity of FRP pultruded profiles also helps in environments where insulation and temperature control are essential. Whether used in extreme heat or freezing temperatures, these profiles offer exceptional performance and longevity.

The Future of Construction with FRP Pultruded Profiles

As industries continue to innovate and look for materials that offer both performance and sustainability, FRP pultruded profiles are becoming increasingly popular. With growing awareness of the environmental impact of traditional materials like steel and concrete, many industries are turning to FRP profiles for their energy efficiency, low environmental footprint, and recyclability. The ability of FRP pultruded sections to reduce overall material usage, transportation costs, and maintenance efforts makes them a smarter choice for long-term projects.

The continuous advancements in FRP pultruded profiles technology allow for even more precise manufacturing and customized solutions. From smart homes to advanced industrial projects, the integration of FRP pultruded profiles into construction and manufacturing is set to revolutionize the way we build and design. Their application in eco-friendly infrastructure, renewable energy projects, and durable, cost-effective materials ensures that FRP profiles will play a major role in shaping the future of construction and industry worldwide.

FRP Profiles FAQs

What are the main benefits of using FRP profiles in construction?

FRP profiles offer excellent corrosion resistance, strength, lightweight properties, and are highly customizable. They are ideal for use in harsh environments and can significantly reduce maintenance costs.

How are FRP pultruded profiles made?

FRP pultruded profiles are created using the pultrusion process, where continuous fibers are pulled through resin and cured under heat, resulting in strong, durable profiles that can be customized into various shapes.

Are FRP pultruded sections cost-effective for large projects?

Yes, while FRP pultruded sections may have a higher upfront cost compared to traditional materials, their durability, low maintenance, and reduced weight make them a cost-effective choice in the long run.

Can FRP pultruded profiles be used for structural applications?

Absolutely! FRP pultruded profiles are ideal for structural applications, including beams, channels, and support elements, offering high strength and durability while reducing overall load.

Where are FRP pultruded profiles commonly used?

FRP pultruded profiles are commonly used in industries such as construction, marine, automotive, and telecommunications due to their strength, corrosion resistance, and versatility in various applications.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingЯңалыкларNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersЯңалыкларNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessЯңалыкларNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesЯңалыкларNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectЯңалыкларNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesЯңалыкларNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingЯңалыкларNov.11,2025