loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Designs and Applications of Grating Systems for Enhanced Performance and Efficiency

Exploring GRP Grating Systems Applications, Benefits, and Innovations

GRP (Glass Reinforced Plastic) grating systems have emerged as a revolutionary solution in various industries, offering exceptional benefits that traditional materials such as steel or wood cannot match. This article examines the advantages of GRP grating systems, their applications across different sectors, and the innovations that continue to enhance their functionality.

What is GRP Grating?

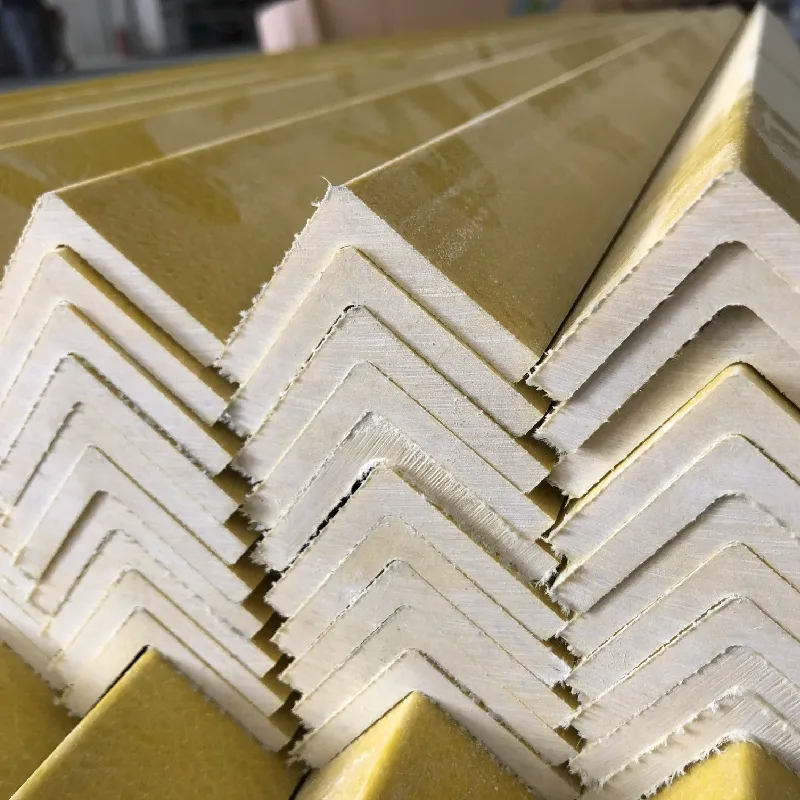

GRP grating is a composite material made from a combination of glass fibers and a polymer resin. This unique combination results in a lightweight, strong, and corrosion-resistant product that can withstand harsh environments. These gratings are produced in various forms, including standard panels, pultruded sections, and molded products, catering to specific needs in different applications.

Key Benefits of GRP Grating Systems

1. Corrosion Resistance One of the standout features of GRP grating is its resistance to corrosion. Unlike traditional materials that succumb to rust and decay when exposed to moisture and chemicals, GRP grating remains unaffected, making it suitable for use in environments such as wastewater treatment plants, chemical processing facilities, and marine applications.

2. Lightweight and Easy Installation GRP grating is significantly lighter than steel or aluminum, making it easier to handle and install. This property not only reduces labor costs but also allows for more efficient transportation and installation processes.

3. Safety Features GRP gratings are designed with safety in mind. They often come with high-slip resistance surfaces, making them suitable for use in areas where wet or slippery conditions are prevalent, such as in factories and outdoor platforms. Additionally, the non-conductive nature of GRP makes it ideal for electrical safety in industrial applications.

4. Durability Due to their inherent strength and resistance to a variety of environmental factors, GRP grating systems have an extended lifespan, which translates to lower long-term maintenance and replacement costs.

grp grating systems

5. Customizability GRP grating can be manufactured in various colors, sizes, and configurations, allowing for tailored solutions that meet the specific aesthetic and functional needs of different projects.

Applications of GRP Grating Systems

The versatility of GRP grating lends itself to a wide range of applications

- Industrial Flooring GRP grating is commonly used as flooring in factories, chemical plants, and warehouses where chemical spills and high foot traffic are concerns. - Walkways and Platforms Its lightweight nature and anti-slip surface make GRP an excellent choice for walkways and access platforms in construction sites and public areas. - Marine Applications GRP grating systems are ideal for piers, docks, and shipbuilding facilities due to their resistance to saltwater corrosion. - Wastewater Treatment The durability and chemical resistance of GRP gratings make them suitable for covering channels and walkways in wastewater treatment facilities.

Innovations in GRP Grating Technology

As technology advances, the capabilities of GRP grating systems continue to evolve. Current innovations focus on enhancing the mechanical properties of GRP through improved fiber reinforcement techniques, as well as developing new resin formulations to further increase resistance to chemicals and UV radiation. Additionally, advances in manufacturing processes, such as automated pultrusion techniques, are lowering production costs and improving quality control.

Conclusion

GRP grating systems represent a significant advancement in the field of industrial materials. Their numerous benefits, including resistance to corrosion, lightweight characteristics, and safety features, make them suitable for a plethora of applications across different sectors. As innovations in GRP technology continue to unfold, the future looks bright for this versatile material, positioning it as a leading choice in grating solutions for decades to come. By investing in GRP systems, industries can achieve enhanced efficiency, safety, and cost-effectiveness.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025