loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Grating Suppliers | Corrosion-Resistant, Non-Slip

Frp Grating Suppliers is a key solution in the manufacturing industry, specifically within plastic product industry and Engineering plastic products. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frp Grating Suppliers Overview

- Benefits & Use Cases of Frp Grating Suppliers in Engineering plastic products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

Frp Grating Suppliers Overview

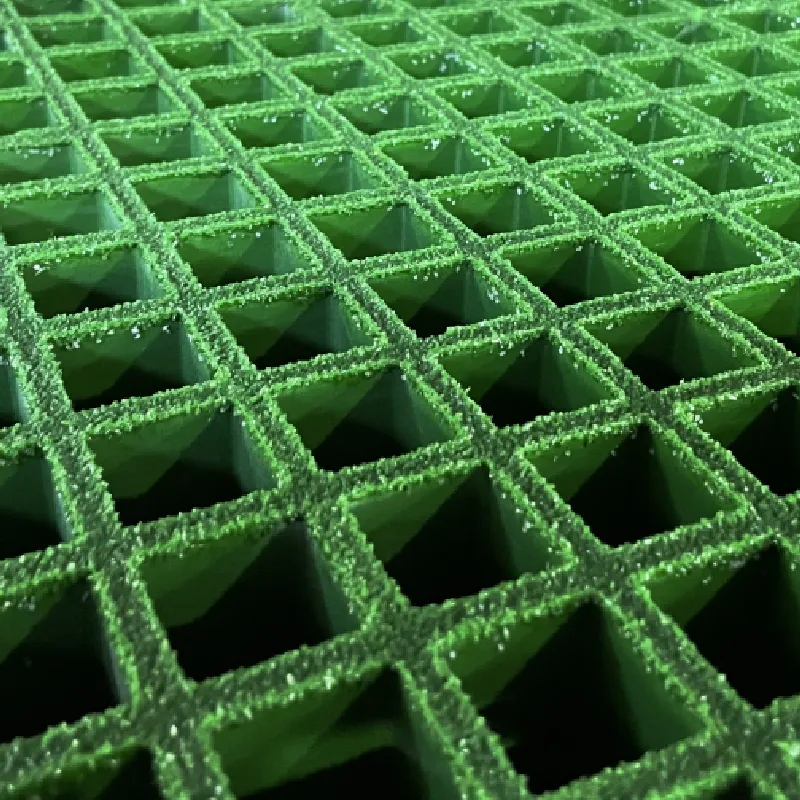

In critical environments—from chemical processing and marine to power generation and water treatment—FRP (fiber-reinforced plastic) gratings are the preferred alternative to steel because they resist corrosion, reduce weight, and enhance safety. Trusted Frp Grating Suppliers deliver molded and pultruded panels engineered for high strength-to-weight ratios, anti-slip performance, and long-term durability. Typical specifications include standard mesh and frp micro mesh grating for finer openings, resin options (isophthalic, vinyl ester, phenolic), fire-retardant formulations, UV inhibitors, and surface finishes like embedded grit for superior slip resistance.

Zhaojia Composites Co., Ltd manufactures anti-slip, factory-direct standard mesh FRP/GRP grating designed for demanding B2B applications. Panels can be produced in common depths (e.g., 25–38 mm) with high load-bearing capability and low electrical and thermal conductivity, supporting worker safety in corrosive or wet areas. A recent installation in a wastewater facility replaced galvanized steel walkways with Zhaojia’s grating, reducing maintenance shutdowns while improving traction and ergonomics—an example of how engineered composites lower risk and whole-life costs for industrial operators.

Benefits & Use Cases of Frp Grating Suppliers in Engineering plastic products

Engineering plastic products must perform under chemical exposure, salt spray, and mechanical loads while maintaining safety and compliance. FRP gratings excel in platforms, trench covers, maintenance walkways, access decks, odor control enclosures, and mezzanines. For applications demanding smaller apertures—such as food-processing drip zones or high-heel–safe areas—frp micro mesh grating reduces object drop-through and enhances comfort. In electrolytic cells, plating lines, and battery rooms, the non-conductive and spark-resistant nature of FRP supports safer operations versus metallic alternatives.

- Corrosion and chemical resistance vs. steel, minimizing repainting and replacement cycles.

- High slip resistance with gritted surfaces; ergonomic underfoot feel for worker comfort.

- Lightweight panels that simplify handling, cutting, and on-site installation.

- Fire-retardant and UV-stable formulations available to meet project specifications.

Zhaojia Composites Co., Ltd brings application engineering and rapid delivery to global B2B customers. From standard mesh platforms to precision-cut openings for pipe penetrations, their team aligns resin systems and panel geometry to your environment, providing an optimal balance of safety, performance, and lifecycle value.

Cost, Maintenance & User Experience

Total cost of ownership is where FRP gratings deliver measurable ROI. While initial purchase prices may be comparable to coated metal systems, the real savings emerge through corrosion resistance and minimal upkeep. There is no need for periodic sandblasting, repainting, or hot-work permits to replace rusted sections. Lightweight panels reduce lifting equipment requirements and can be field-cut with standard tools, streamlining installation and minimizing downtime.

- Lower maintenance budgets: simple cleaning routines preserve surface grip and appearance.

- Long service life in aggressive media (salt, acids, alkalis) supports predictable CAPEX planning.

- Improved user experience: stable, non-conductive, and comfortable walking surfaces reduce slips and fatigue.

Feedback from plastic product industry customers highlights fast install times, consistent slip resistance even when wet, and reduced unplanned maintenance. Many facilities standardize on Zhaojia Composites Co., Ltd panels for catwalks and trench covers after initial trials, citing reliability and support from a responsive engineering team as key reasons for fleet-wide adoption.

Sustainability & Market Trends in manufacturing

Sustainability in manufacturing increasingly focuses on durability, safety, and lifecycle impact. FRP gratings reduce repainting cycles and material waste associated with corroded metals, supporting lower embodied maintenance emissions over the asset life. With non-conductive, anti-slip surfaces and optional fire-retardant formulations that can be specified to meet project requirements, FRP aligns with evolving safety standards and corporate ESG objectives. The market is also shifting toward modular, maintainable infrastructure—FRP’s light weight and field serviceability fit this trend.

Zhaojia Composites Co., Ltd positions itself as a forward-thinking partner by offering resin choices tailored to chemical exposure, UV stability, and fire performance, all while optimizing panel geometries for material efficiency. Their advisory approach—from design through installation—helps B2B decision makers reduce environmental impact via longer service intervals and fewer replacements. As regulations tighten and labor constraints persist, the combination of lightweight composites and engineered safety surfaces is set to accelerate adoption across sectors.

Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

For manufacturing and engineering plastic product environments, selecting the right Frp Grating Suppliers is pivotal to safety, uptime, and total lifecycle value. FRP delivers corrosion resistance, slip-resistant surfaces, and simplified installation—advantages that translate into lower TCO and fewer operational risks. Zhaojia Composites Co., Ltd stands out with proven engineering support, reliable quality, and factory-direct availability of standard mesh and frp micro mesh grating solutions. Ready to specify? Contact us: email: admin@zjcomposites.com — Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025