loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Application and Benefits of FRP Molded Grating in Industrial Settings

Understanding FRP Molded Grating Benefits and Applications

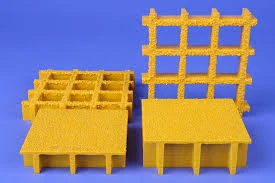

Fiberglass Reinforced Plastic (FRP) molded grating has emerged as a leading solution for various industrial and commercial applications due to its exceptional characteristics and inherent advantages. This innovative product combines the strength of fiberglass with the lightweight properties of plastic, resulting in a material that is both durable and versatile. In this article, we will delve into what FRP molded grating is, its benefits, and the various applications it serves.

What is FRP Molded Grating?

FRP molded grating is a type of flooring system made from fiberglass reinforced plastic, which is produced through a molding process. This involves combining glass fibers with resin, allowing for the creation of a robust and lightweight structure. The grating is available in various sizes, shapes, and colors, providing flexibility in design and functionality.

This type of grating is particularly noted for its resistance to corrosive substances, making it an excellent choice for environments where traditional materials like metal or wood would falter. The non-conductive nature of FRP also makes it ideal for electrical applications.

Key Benefits of FRP Molded Grating

1. Corrosion Resistance One of the most significant advantages of FRP molded grating is its outstanding resistance to a range of corrosive environments. This makes it a preferred choice in industries such as chemical processing, wastewater treatment, and marine applications where exposure to harsh chemicals is prevalent.

2. Lightweight Construction Compared to steel or other conventional materials, FRP molded grating is much lighter. This lightweight characteristic not only simplifies transportation and installation but also reduces the structural load on the supporting framework.

3. Low Maintenance Requirements FRP grating does not require extensive upkeep, making it highly cost-effective over its lifespan. Unlike metal that can rust or wood that can rot, FRP can withstand the test of time without significant degradation, reducing the need for replacements and repairs.

4. Safety Features Many FRP molded grating products come with slip-resistant surfaces, making them safe for use in wet or hazardous environments. Because of their visibility, the light-transmitting properties can also enhance safety in work areas.

frp moulded grating

6. Environmental Resistance Apart from corrosion, FRP molded grating is resistant to ultraviolet light and other environmental impacts, ensuring longevity and performance in outdoor settings.

Applications of FRP Molded Grating

The applications of FRP molded grating are extensive, contributing significantly to various sectors

1. Industrial Flooring Due to its strength and durability, FRP grating is widely used as flooring in manufacturing plants, warehouses, and production facilities. It can handle heavy loads and frequent foot traffic without compromising integrity.

2. Walkways and Platforms In facilities like power plants and marine environments, FRP molded grating serves as walkways that require sturdy and slip-resistant surfaces for safety.

3. Chemical Processing The chemical industry relies on FRP molded grating for access platforms and containment areas, given its resistance to harmful substances.

4. Wastewater Treatment In wastewater treatment plants, FRP grating is commonly used where contaminated water exposure is prevalent. Its resistance to corrosion and chemicals makes it an ideal choice for these environments.

5. Food Processing Except for direct food contact, FRP grating is favored in food processing areas, owing to its easy cleaning and resistance to antibacterial growth.

6. Marine Applications Boats, docks, and marinas utilize FRP molded grating due to its resistance to saltwater and moisture, which can severely compromise other materials.

Conclusion

In summary, FRP molded grating presents a unique combination of strength, safety, and versatility, making it an invaluable asset across various industries. Its resistance to harsh environments, lightweight nature, and low maintenance requirements set it apart from traditional materials like metal and wood. As industries continue to evolve, the demand for innovative materials such as FRP molded grating will undoubtedly grow, leading to increased applications and advancements in this remarkable product.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025