- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

More Language

Untranslated

Jan . 09, 2025 12:34

Back to list

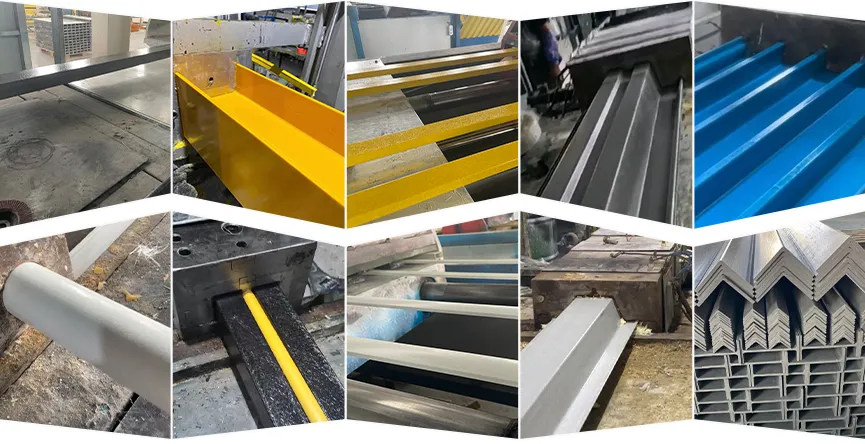

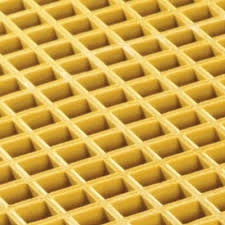

frp micro mesh grating

In the realm of modern construction and industrial applications, FRP grating panels have emerged as a revolutionary solution, offering unparalleled benefits in terms of durability, versatility, and safety. FRP, or Fiber Reinforced Plastic, grating panels are composed of a matrix of resin and fiberglass, which endows them with exceptional properties ideal for a variety of environments. Unlike traditional materials such as steel or aluminum, FRP grating panels are lightweight, non-corrosive, and extremely resilient to harsh environmental conditions including chemical exposure and extreme temperatures.

Authoritativeness in the field of FRP grating panels can be attributed to the rigorous testing protocols that these products undergo. Compliance with international standards such as ASTM and ISO ensures that each panel meets the highest quality benchmarks. Leading manufacturers in the industry are regularly audited and certified, providing end-users with the assurance that they are investing in a product that will not only meet but exceed regulatory and safety expectations. Trustworthiness of FRP grating panels is further reinforced by the positive feedback from users and industry experts. Testimonials from engineers and safety officers highlight the confidence they have in FRP panels for preventing workplace accidents and enhancing operational efficiency. Moreover, the environmental benefits of choosing FRP over traditional materials, due to their low carbon footprint and sustainable production processes, add an additional layer of trust from an ecological perspective. In conclusion, FRP grating panels represent a cutting-edge solution that embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. For industries looking to optimize their infrastructure with a focus on safety, durability, and cost-effectiveness, FRP grating panels stand out as an exceptional choice. As the demand for more sustainable and reliable construction materials continues to rise, the prominence of FRP grating panels is expected to bolster, setting a new standard in industrial applications across the globe.

Authoritativeness in the field of FRP grating panels can be attributed to the rigorous testing protocols that these products undergo. Compliance with international standards such as ASTM and ISO ensures that each panel meets the highest quality benchmarks. Leading manufacturers in the industry are regularly audited and certified, providing end-users with the assurance that they are investing in a product that will not only meet but exceed regulatory and safety expectations. Trustworthiness of FRP grating panels is further reinforced by the positive feedback from users and industry experts. Testimonials from engineers and safety officers highlight the confidence they have in FRP panels for preventing workplace accidents and enhancing operational efficiency. Moreover, the environmental benefits of choosing FRP over traditional materials, due to their low carbon footprint and sustainable production processes, add an additional layer of trust from an ecological perspective. In conclusion, FRP grating panels represent a cutting-edge solution that embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. For industries looking to optimize their infrastructure with a focus on safety, durability, and cost-effectiveness, FRP grating panels stand out as an exceptional choice. As the demand for more sustainable and reliable construction materials continues to rise, the prominence of FRP grating panels is expected to bolster, setting a new standard in industrial applications across the globe.

Share

Next:

Latest news

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025