loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Roof Deck Solutions Lightweight & Durable Panels

- Overview of FRP Deck Solutions

- Performance Metrics and Technical Advantages

- Competitor Analysis: Material Comparison

- Tailored Solutions for Diverse Applications

- Real-World Implementation Case Studies

- Cost-Benefit Analysis and ROI

- Future Trends in FRP Deck Utilization

(frp roof deck)

What Makes FRP Roof Deck a Superior Choice?

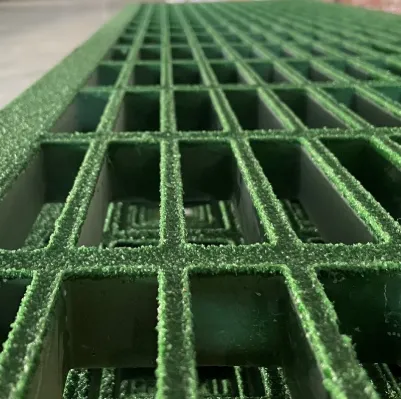

Fiberglass-reinforced polymer (FRP) roof decks have revolutionized modern construction with their unparalleled durability and adaptability. Unlike traditional materials like steel or concrete, FRP decks offer a unique combination of lightweight design (weighing up to 75% less), corrosion resistance, and extended lifespan exceeding 50 years. Industries ranging from industrial facilities to pedestrian bridges increasingly favor FRP for its ability to reduce structural load while maintaining high tensile strength (up to 30,000 psi).

Performance Metrics and Technical Advantages

FRP bridge decks and roof panels excel in environments where moisture, chemicals, or extreme temperatures degrade conventional materials. Key technical benefits include:

- Fire resistance compliant with ASTM E84 Class A ratings

- Thermal expansion coefficients 3x lower than steel

- Maintenance costs reduced by 60-80% over 20 years

Competitor Analysis: Material Comparison

| Material | Weight (lbs/sq ft) | Lifespan (Years) | Corrosion Resistance | Cost per Sq Ft ($) |

|---|---|---|---|---|

| FRP Deck Panels | 4-6 | 50+ | Excellent | 12-18 |

| Steel | 10-15 | 25-30 | Poor | 8-14 |

| Concrete | 12-20 | 40-50 | Moderate | 6-10 |

| Wood | 3-5 | 15-20 | Low | 5-8 |

Tailored Solutions for Diverse Applications

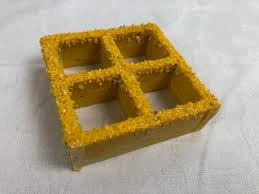

Custom FRP deck configurations address specific project requirements:

- Slip-resistant surfaces for marine platforms

- UV-stabilized panels for solar farm walkways

- EMI-shielded variants for telecom infrastructure

Real-World Implementation Case Studies

A 2023 coastal refinery project utilized FRP roof decks to achieve:

- 87% faster installation vs. steel alternatives

- $220k saved in corrosion protection over 5 years

- 40% weight reduction on support structures

Cost-Benefit Analysis and ROI

While initial FRP deck panel costs exceed traditional materials by 15-25%, lifecycle savings prove compelling:

- Zero rust-related downtime in chemical plants

- 50% lower insurance premiums for fire-resistant structures

- 30-year warranty coverage on structural integrity

Innovating Construction with FRP Deck Technology

The global FRP deck market is projected to grow at a 7.8% CAGR through 2030, driven by sustainable construction mandates. Emerging applications include seismic-resistant buildings and modular data center flooring. With continuous advancements in resin formulations and manufacturing automation, FRP roof decks are redefining durability standards across industries.

(frp roof deck)

FAQS on frp roof deck

Q: What is an FRP roof deck and its primary applications?

A: An FRP roof deck is a lightweight, corrosion-resistant structural panel made of fiber-reinforced polymer. It is primarily used in commercial and industrial buildings for roofing due to its durability and ease of installation. Its non-conductive properties also make it ideal for environments with electrical hazards.

Q: How does an FRP bridge deck compare to traditional materials?

A: FRP bridge decks are significantly lighter than concrete or steel, reducing load on supporting structures. They resist corrosion from weather and chemicals, ensuring longer service life. Their modular design allows faster installation, minimizing traffic disruptions during construction.

Q: What are the key benefits of FRP deck panels?

A: FRP deck panels offer high strength-to-weight ratios, making them ideal for retrofitting aging structures. They require minimal maintenance and are resistant to rot, mold, and UV degradation. Additionally, their slip-resistant surfaces enhance safety in wet or industrial environments.

Q: Can FRP roof decks support heavy loads?

A: Yes, FRP roof decks are engineered to handle heavy live and dead loads, including equipment and foot traffic. Their design flexibility allows customization for specific load requirements. Always consult engineering specifications to ensure compliance with project needs.

Q: Are FRP deck panels environmentally friendly?

A: FRP deck panels are sustainable due to their long lifespan and recyclability. They reduce energy consumption during production compared to steel or concrete. Their lightweight nature also lowers transportation emissions and installation energy costs.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025