loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ก.พ. . 15, 2025 00:28

Back to list

frp rod price

The cost of FRP (Fiber Reinforced Polymer) rods has garnered attention in various industries due to their increasing application in construction, manufacturing, and infrastructure projects. Understanding the factors influencing the price of FRP rods helps industry professionals make informed purchasing decisions.

Certifications and compliance with industry standards can influence FRP rod prices as well. Products that meet rigorous industry standards or possess certifications from recognized bodies often command higher prices due to their proven reliability and quality assurance. For companies seeking top-tier, certified solutions for critical applications, investing in certified FRP rods may be non-negotiable, despite the premium cost. In addition, the competitive landscape within the FRP rod market can influence prices. Large, established manufacturers may offer economies of scale, enabling them to price their products competitively. In contrast, niche or specialized manufacturers might focus on customization and unique offerings, which could result in higher pricing for tailored solutions. Lastly, macroeconomic factors, including currency fluctuations, trade policies, and global supply chain disruptions, can have an indirect yet substantial impact on FRP rod prices. Companies must navigate these complexities to maintain budgetary control over their projects and minimize the risk of unforeseen expenses. In conclusion, the price of FRP rods is shaped by a myriad of factors, including raw material costs, production processes, market demand, geographic considerations, certifications, and the competitive landscape. Understanding these elements allows companies to anticipate price changes and make strategic decisions that align with their budgetary and project goals. By remaining informed and adaptable, businesses can effectively manage the costs associated with incorporating FRP rods into their operations, ensuring a balance between quality, performance, and expense.

Certifications and compliance with industry standards can influence FRP rod prices as well. Products that meet rigorous industry standards or possess certifications from recognized bodies often command higher prices due to their proven reliability and quality assurance. For companies seeking top-tier, certified solutions for critical applications, investing in certified FRP rods may be non-negotiable, despite the premium cost. In addition, the competitive landscape within the FRP rod market can influence prices. Large, established manufacturers may offer economies of scale, enabling them to price their products competitively. In contrast, niche or specialized manufacturers might focus on customization and unique offerings, which could result in higher pricing for tailored solutions. Lastly, macroeconomic factors, including currency fluctuations, trade policies, and global supply chain disruptions, can have an indirect yet substantial impact on FRP rod prices. Companies must navigate these complexities to maintain budgetary control over their projects and minimize the risk of unforeseen expenses. In conclusion, the price of FRP rods is shaped by a myriad of factors, including raw material costs, production processes, market demand, geographic considerations, certifications, and the competitive landscape. Understanding these elements allows companies to anticipate price changes and make strategic decisions that align with their budgetary and project goals. By remaining informed and adaptable, businesses can effectively manage the costs associated with incorporating FRP rods into their operations, ensuring a balance between quality, performance, and expense.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

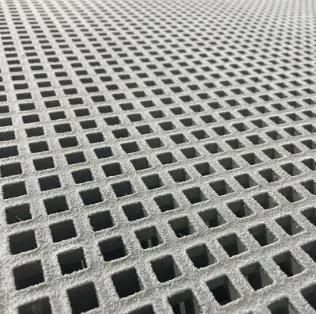

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025